With the winter holidays here, who better to warn you about the lurking dangers and offer safety solutions than Haws™.

Holiday Safety Statistics (according to the National Fire Protection Agency)

- From 2012-2016, an average of 170 home fires were started from Christmas trees per year.

- Christmas Day & Christmas Eve follow Thanksgiving as the peak days for home cooking fires.

- The leading factor in cooking fires and fire deaths is unattended cooking.

- Christmas Day, New Year’s Day, & New Year’s Eve are the top 3 days for home candle fires.

- Alcohol-impaired fatalities represent about one-third of the automobile fatalities on Christmas, Thanksgiving, & New Year’s. (Injury Facts 2017)

Safety Tips:

- Use a designated driver

- Check food regularly

- Keep children out of the kitchen

- Timers are a great way to remind yourself that the stove or oven is still on

- Keep trees away from any heating sources

- Have a functional fire extinguisher

- Be sure to turn off all appliances when done

- Never use water to put out a grease fire!

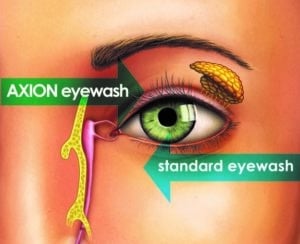

Additionally, the Haws Model 7620 AXION® eyePOD® is a convenient safety tool to keep in your home at all times in case of an emergency. The eyePOD® is an eyewash that is easily mounted onto your faucet to provide a Medically Superior Response consistent with all EMT, emergency room and doctor office protocols by sweeping contaminants away from the vulnerable nasal cavity. Find out more about the model 7620 and more Haws products by visiting the website at: https://www.hawsco.com.

Happy Holidays to all!

Post written by Hayden Del Dotto

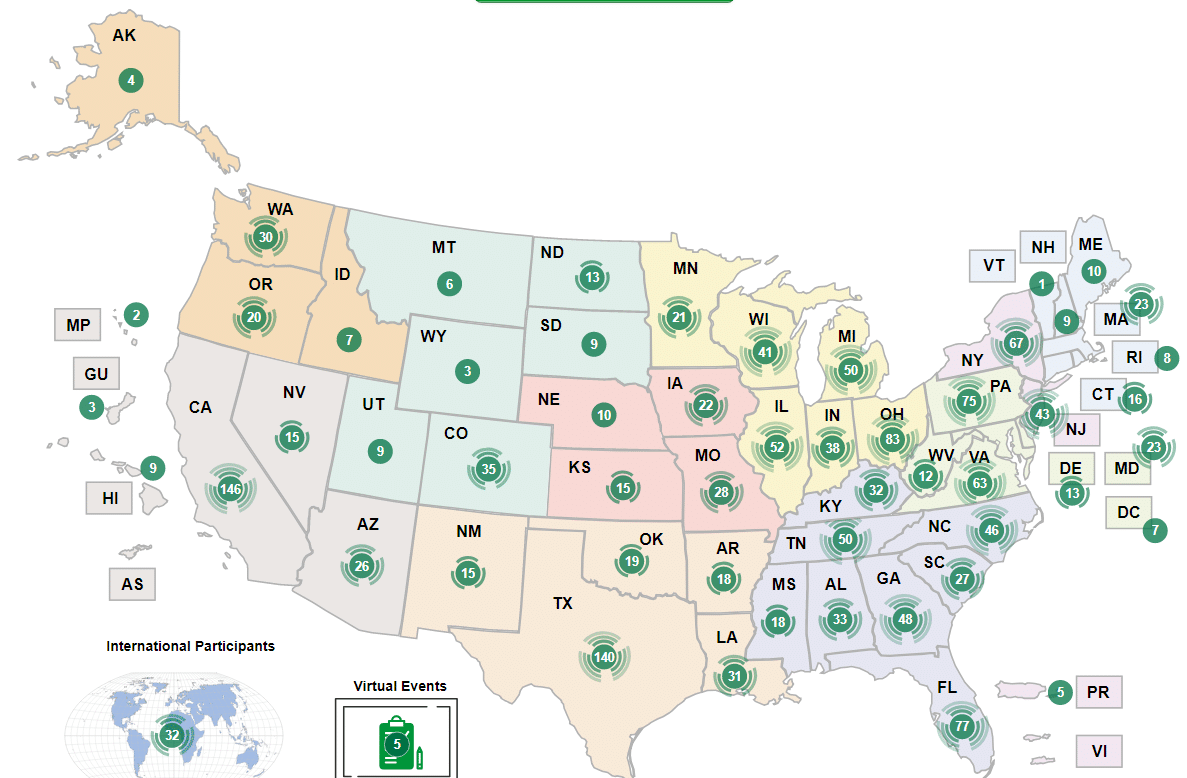

OSHA’s Safe + Sound Week

This nationwide event is taking place Aug. 13-19, 2018. Led by OSHA, Safe + Sound Week is meant to raise awareness and understanding of the value of safety and health programs that include management leadership, worker participation, and a systematic approach to finding and fixing hazards in workplaces. What are you doing to make your workplace as safe as can be? Want to see what others have done in the past? Click here to view a webinar put out by the US Department of Labor on YouTube.

Participant Numbers by State

Safety Equipment on College CampusesBy: Joanne Benz, Haws

Injuries caused during a chemical spill back in 2016 at Sacramento State College set off an alarm with officials at the California State Auditor’s office. The California State University Chancellor’s Office claimed that it does not consider itself as an oversight entity responsible for health and safety, but instead provides guidance, resource materials and collaboration. Most college campuses use hazardous material for instruction and research. Students and employees can be exposed to chemicals in laboratories, classrooms and stockrooms. The Auditor also found that campuses do not always conduct regular inspections of safety equipment such as emergency showers and/or emergency eye washes. After the auditor found that 46% of the 23 California State Universities do not seek input when assessing risk to employ health and safety in chemical stockrooms or laboratory areas. Since the audit, the CSU Chancellor’s office and university officials involved concurred and said they will comply with the auditor’s recommendation. The Chancellor’s Office now plans to conduct health and safety audits at all 23 campuses beginning in 2019. Four CSU Sacramento employees filed an $80 million claim against the university over the chemical spill.

Haws® Services is a warranty and service provider for all brands of emergency shower and eye/face wash products to ensure your emergency equipment is ANSI compliant and functioning properly. From startup and commissioning to annual inspections and preventative maintenance, Haws Services‘ experts specialize in emergency response equipment.

Learn more about our service offerings here. We take the burden off you and your employees so that you can rest assured that students and faculty get the help they need when they need it.

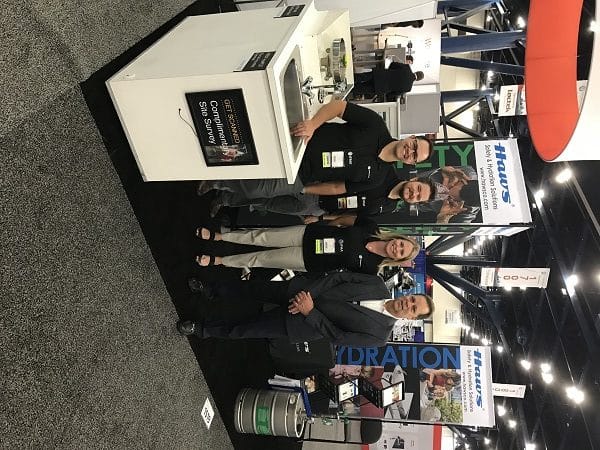

Haws® Attends IFMA & A+A in OctoberHaws® exhibited at the recent International Facility Management Association (IFMA) World Workplace Conference & Expo October 18-20, 2017 in Houston, Texas. The World Workplace expo is an event geared toward learning and relationship-building within the facility management field. Attendees were able to see hundreds of Facility Management toys, tools, and resources from the leading names in FM solutions, including Haws. The attendees were able to see product demonstrations, attend informational sessions, and have one-on-ones with exhibitors. Haws was in a unique position to be the only Emergency Response Equipment and Hydration Products manufacturer at this event.

Haws AG also displayed at the A+A in Dusseldorf Germany. All aspects of safety, security, and health at work were brought together October 17-20, 2017 at the international trade forum that is A+A. Haws was able to present our emergency equipment and safety solutions to a global and highly qualified expert audience of decision-makers.

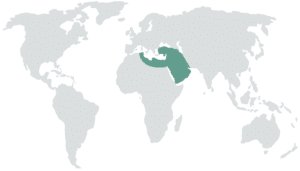

Haws – Switzerland announced its expansion into new markets in the Middle East, increasing its investment and presence to come closer to partners in key markets. This new extension will provide immediate access for customers in the region to help Haws better serve their needs and to develop stronger partnerships with local entities.

Haws – Switzerland announced its expansion into new markets in the Middle East, increasing its investment and presence to come closer to partners in key markets. This new extension will provide immediate access for customers in the region to help Haws better serve their needs and to develop stronger partnerships with local entities.

Recently, Haws welcomed two regional sales team members, Sampeep Verma and Michael Alex, as Business Development Managers – Middle East. Mr. Verma and Mr. Alex split territory coverage with specific regions assigned.

“Over the last 30 years, we have made tremendous progress in establishing Haws as a significant player in the EMEA safety equipment marketplace and expanding our reach to local markets. As one of the fastest growing markets globally, Middle East is an important and strategic region to continue our growth plans,” said Urs Weder, Manager Director of Haws – AG.

The Haws team will be showcasing new products and services at the A+A International Trade Fair and Congress in Dusseldorf in October in Hall 7A at Booth F13.

For more information, visit www.Haws.ch or [email protected].

OSHA and ANSI Requirements for Eyewash and Safety Showers

[via LabManager.com]

ANSI standard Z358.1 is detailed in terms of defining what is appropriate for safety showers and eyewash stations.

As lab managers and employees, we know that many inorganic chemicals (such as the mineral acids and alkalis) are corrosive to the skin and eyes. Likewise we are aware that many organic chemicals (such as acid halides, phenols, and so on) are corrosive and often toxic. Yet we Safety Guys are continually shocked by laissez-faire attitudes toward the use and maintenance of basic safety equipment by lab personnel, and the resultant unnecessary injuries.

One extreme example we constantly recall is the tragic UCLA accident just a few years ago, which resulted in a fatality from chemical burns.1 And we recently noticed a post on the American Industrial Hygiene Association pages for Lab Safety Chemical Exposure Incidents, where improper use of an eyewash resulted in a trip to the emergency room.2

The worker was using a fluorescent stain in the cytogenetics lab and felt something splash into his eyes. He was not wearing safety goggles or glasses. (D’oh!) Long story shortened, he flushed his eyes at the nearest eyewash, but they remained irritated and began to swell shut, necessitating a visit to the emergency room. Back at work a few days later, he noticed a coworker using the same eyewash to clean glassware and stainless steel trays, which were left resting in the sink in a cleaning solution. (What?!)

What does OSHA say?

In 29 CFR 1910.151 Medical Services and First Aid, it states that “where the eyes or body of any person may be exposed to injurious corrosive materials, suitable facilities for quick drenching or flushing of the eyes and body shall be provided within the work area for immediate emergency use.”3 OSHA doesn’t provide more specifics regarding what constitutes “suitable” or how “immediate” is defined. So how do we know if we are meeting the intent of the law?

Fortunately, we have the American National Standards Institute (ANSI), and their consensus standard Z358.1, last updated in 2014. This ANSI standard is very detailed in terms of defining what is appropriate for safety showers and eyewash stations. In fact, OSHA uses this reference as a guide when inspecting facilities. So let’s review what is “recommended” for acceptable safety equipment.

Safety shower specs

Begin by checking your facilities for the proper hardware, as recommended by Z358.1. Rest assured that OSHA will, should one or more agents show up for an inspection. For safety showers, the shower head must be capable of flowing 20 gallons per minute (gpm) at 30 psi and producing a 20-inch diameter spray pattern at 60 inches above the surface where the user stands. The center of the sprayhead pattern should be at least 16 inches from any wall, door, or obstruction. It is recommended that the shower head be mounted between 82 and 96 inches off the floor, with the valve no higher than 69 inches.

Eyewash specs

Eyewash stations target just the eyes and therefore have a lower flow requirement. ANSI Z358.1 recommends a flow of 0.4 gpm also at 30 psi. The nozzles should be at least six inches from any obstruction and mounted between 33 and 45 inches above the floor. An eyewash gauge should be used to verify and test the flow pattern.

Requirements for both

Both safety showers and eyewash stations must be able to provide the recommended flow for at least 15 minutes. This usually translates into having the equipment plumbed in with hard connections to the water supply. For example, a quick calculation for the safety shower at 20 gpm yields 300 gallons needed. Self-contained or personal wash devices are allowed, but they are considered supplemental units that can provide immediate flushing while transiting to the permanent fixture.

If the local climate presents potential for freezing conditions, the equipment must be designed to avoid freezing or protected against that situation. Activation valves must open within one second and remain open until intentionally closed or turned off. It goes without saying that these safety devices should be constructed of corrosion-resistant materials.

The 2014 update to Z358.1 added two important criteria. The first is that the requirement for tepid water is now defined as having a temperature of between 60 and 100 degrees Fahrenheit (15 to 37 degrees Celsius). The second change addresses simultaneous operation for combination units. This means that if you have a drench shower combined with an eyewash station, both devices must provide adequate flows and be fully operable at the same time.

Finally and most importantly, consider the location of equipment. We know you have the 10-second rule etched into your brain, as that is the most critical element when it comes to safety showers and eyewashes. This means that travel to the unit should be under 10 seconds for all hazardous areas that need this equipment. This equals about 55 feet. In addition, the drench shower or eyewash must be on the same level as the hazard and have a clear path for travel. We recommend painting or marking the floor area underneath the shower to help keep it clear. Z358.1 also recommends equipment be installed in a brightly lit area and marked with a highly visible safety sign.

Maintenance and training

The last thing you want is to rush to the eyewash or shower, only to be drenched with nasty, sediment-laden water. ANSI recommends flushing all equipment weekly to verify proper flow, and clearing the plumbing of any deposits. If your facility does not have floor drains installed, remember to bring a large, plastic trash can to catch the water. The weekly flushing can also provide a great training opportunity to refresh the operation and travel paths for your employees.

If you want to find out about the ANSI/ISEA Z358.1 significant requirements, attend our free 1-hour webinar on September 21st, 2017.

Register now and become subject matter experts of your emergency eyewash and shower equipment including weekly and annual testing. Request a certificate of attendance after the webinar.

This free webinar will cover:

• ANSI/ISEA Z358.1 significant requirements

• Important 2014 revision highlights

• Compliance best practices

• Live Q&A

WHAT: All You Need to Know About ANSI Z358.1 Webinar

WHEN: September 21, 2017 from 10am-11am PT / 1pm-2pm ET

PRESENTER: Justin Dunn, Product Specialist/Trainer and Samantha Hoch, Marketing Strategist

HOW: Register for free

Attendees will receive these complimentary materials after the webinar:

• OSHA white paper

• Weekly and Annual ANSI Checklist

• Access to On-Demand Webinar

References

1. “tert-Butyllithium Claims Fellow Chemist at UCLA,” Chemistry Blog, January 19, 2009, http://www.chemistry-blog.com/2009/01/20/tert-butyllithium-claims-fellow-chemist-at-ucla/.

2. “Lab Safety Chemical Exposures Incidents,” American Industrial Hygiene Association, https://www.aiha.org/get-involved/VolunteerGroups/LabHSCommittee/Incident%20Pages/Lab-Safety-Chemical-Exposures-Incidents.aspx.

3. “Medical Services and First Aid,” US Department of Labor, Occupational Health and Safety Administration, https://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=STANDARDS&p_id=9806.

Haws Receives Safety 2017 Attendee Choice Award

ISHN’s annual hands-on safety and health products and services awards – a complement to the Reader’s Choice Awards — are based on voting by attendees at the American Safety of Safety Engineers (ASSE) annual professional development conference.

Haws is proud to announce that our Tempered, Gravity-Fed, Portable Eyewash model 7501T is a winner in the category of Emergency Eyewashes at this year ASSE Safety 2017 conference Attendees Choice Award.

Model 7501T is a compact portable tempered eyewash and is ideal for remote locations. The 9-gallon (34 L), gravity-fed, eyewash uses a heated, insulated blanket to provide ANSI compliant tempered potable water in operating temperatures between -30° F (-34° C) and 100° F (38° C) for locations without access to a continuous potable water source. The self-contained heating blanket electrical system uses NEMA 3R rated components. 120V electrical requirement with supplied 8′ power cord.

- Featuring an FDA approved high-density green polyethylene tank easily activated by pulling the yellow activation arm down to the open position

- A wide-fill opening with threaded cap permits easy inspection, cleaning, and filling

- Relocation is simple due to the easily mounted bracket (included) and light design of this 9-gallon (34 L) portable

To see a complete line of Portable Eyewash solutions visit our website.

Haws exhibits at ASSE and SHE

In the month of June, Haws exhibited at two safety expo’s: Safety and Health Expo in London and the ASSE (American Society of Safety Engineers) Expo in Denver, Colorado. Below are some photos highlighting our displays at the successful shows.

How ASSE Safety 2017 Innovations Enhance Employee SafetyAuthors: Scott Francis, Midwest Regional Market Manager, Westex by Milliken and Samantha Hoch, Marketing Communications Strategist, Haws®

![]()

![]()

We believe when it comes to safety, you should not have to compromise. Leaders in the safety industry design innovative, yet functional, equipment to protect workers while on the job. From emergency response equipment to flame resistant (FR) fabrics, today’s safety programs incorporate leading technology to provide a multifaceted plan to combat job-related hazards.

Today, we partnered with Haws, a leading emergency response equipment manufacturer, to preview new safety innovations premiering at the upcoming ASSE Safety 2017 in Denver, June 19-21, 2017.

Westex by Milliken: UltraSoft® Flex

The Westex UltraSoft® line is one of our most popular FR fabrics and has a strong reputation for providing an excellent balance of protection, comfort, and value. Designed with both comfort and safety in mind, UltraSoft® offers arc flash and flash fire protection that you can trust.

At ASSE Safety 2017, booth 1525, we’re debuting the newest evolution of Westex UltraSoft®, UltraSoft® Flex FR fabric, which builds on this trusted line to offer even more flexibility – allowing for superior mobility and maximum comfort.

Westex UltraSoft® Flex provides 50% more stretch than other FR fabrics. According to a wear trial, three out of four workers prefer everyday FR apparel constructed with our new UltraSoft® Flex fabric when working on the job, as it allows them to move freely and comfortably despite the specific task at hand.

In addition to added flexibility, Westex UltraSoft® Flex also offers excellent softness, shrinkage control, and guaranteed flame resistance made possible with our advanced, proprietary engineering process

Westex UltraSoft® Flex is NFPA 2112 certified and provides NFPA 70E Category 2 protection – making it a leading choice for everyday arc flash or flash fire protection in a variety of industries.

UltraSoft® Flex is the FR fabric your employees will want to wear. Multi-hazard protection, increased mobility and superior comfort, Westex UltraSoft® Flex makes adopting everyday FR apparel simple. It removes the decision of protection or comfort on the job and makes both a fundamental benefit of daily FR workwear.

Haws: AXION® MSR

For more than 110 years, Haws has been committed to inventing, designing, and manufacturing hydration equipment as well as standardized and customized emergency response products.

For more than 110 years, Haws has been committed to inventing, designing, and manufacturing hydration equipment as well as standardized and customized emergency response products.

Haws’ core emergency equipment product line includes eyewashes, which remove contaminants from the eyes; eye/face washes, which remove contaminants from the eyes and the face; drench showers, which remove contaminants from the entire body; and an eye/face wash and a drench shower together, which is called a combination unit. They also offer all variations of configurations with stainless steel or ABS plastic options.

Traditional eyewash water flows from the outside-in, pushing contaminants toward the inner corners of the eyes – where susceptible tear ducts, glands, and canals are located. The ideal approach is to sweep contaminants away from the tear ducts to the outside of the eye. Haws’ innovative nature came forth to create the AXION MSR technology, with MSR standing for Medically Superior Response. AXION MSR is the only eye/face wash adhering to this preferred methodology, with inverted water streams gently flushing contaminants away from the sensitive glands and ducts that surround the eye.

The advanced technology process behind the eye/face wash was considered when redesigning emergency response showerheads. The AXION MSR showerhead has a hydrodynamic design to minimize strong physical pressure by releasing smaller, more discreet droplets. In addition, the engineering team improved the conventional showerhead design by spinning the water inlet, making the distribution even across the entire footprint of the flow. These inventive advancements allow for consistent, comfortable water pressure.

The advanced technology process behind the eye/face wash was considered when redesigning emergency response showerheads. The AXION MSR showerhead has a hydrodynamic design to minimize strong physical pressure by releasing smaller, more discreet droplets. In addition, the engineering team improved the conventional showerhead design by spinning the water inlet, making the distribution even across the entire footprint of the flow. These inventive advancements allow for consistent, comfortable water pressure.

To discover more cutting-edge innovations to protect employees while attending ASSE Safety 2017, visit Westex by Milliken at Booth 1525 and Haws at Booth 615.

For more information on the innovations discussed here, view the following resources:

TRADESHOW: Join us @ Safety & Health Expo in London. Your entry is on us!Haws Switzerland  AG invites you to join us at the Safety & Health Expo June 20-22, 2017 at Excel London.

AG invites you to join us at the Safety & Health Expo June 20-22, 2017 at Excel London.

Safety & Health Expo, organized by UBM EMEA, is the UK’s leading global health and safety event, providing visitors with CPD accredited education, the latest health and safety products and services, valuable networking opportunities and much more.

Are you interested in attending? If so, we’d like to offer you a free badge to the expo! Click on this link and fill out your information.

Don’t forget to stop by our Stand No. M215 to learn more about our various product offerings including our EN and ANSI compliant emergency eyewash and shower equipment.

We hope to see you there!

WHITE PAPER: The Value of Wireless Alarms and Monitoring Systems on Emergency EquipmentFederal safety regulations set forth by the Occupational Safety and Health Administration (OSHA) and The American National Standards Institute (ANSI) make the  importance of safety equipment in potentially dangerous working environments clear. However, the stringent guidelines for emergency showers and eyewashes don’t extend to the inclusion of mandatory alarm and electronic monitoring systems on this equipment. This oversight can create unsafe working conditions in even the most well equipped facilities. Not only is this dangerous, it’s also a potential liability.

importance of safety equipment in potentially dangerous working environments clear. However, the stringent guidelines for emergency showers and eyewashes don’t extend to the inclusion of mandatory alarm and electronic monitoring systems on this equipment. This oversight can create unsafe working conditions in even the most well equipped facilities. Not only is this dangerous, it’s also a potential liability.

Alarm and wireless monitoring systems are exactly what you’d imagine. An alarm system is intended to notify the management and personnel of a facility when and where safety equipment is being used.

Download the full white paper for free>>

Haws Receives ISO 9001:2015 Certification

November 4, 2016

[Sparks, Nevada USA] – Haws® is pleased to announce the awarding of its ISO 9001:2015 Certification. The certification was completed by SAI Global registrar who operates a Quality Management System that complies with the requirements of ISO 9001:2015. Organizations are granted a three-year transition period from the ISO 9001:2015 publish date, yet Haws passed the previous (2008) and current version  requirements concurrently. Haws’ scope of certification is for the design and manufacture of drinking fountains and safety equipment including drench showers, hose and spray units, eye/face washes and tempered water blending systems and the distribution of electric water coolers.

requirements concurrently. Haws’ scope of certification is for the design and manufacture of drinking fountains and safety equipment including drench showers, hose and spray units, eye/face washes and tempered water blending systems and the distribution of electric water coolers.

“By obtaining the ISO 9001:2015 certification we are demonstrating our continued dedication to customer satisfaction. The decision to seek this new certification so quickly after it was released emphasizes our commitment to be an innovative company on the front lines in both the hydration and emergency equipment sectors.” says Melanie Mayer, Safety Supervisor/ISO Coordinator.

ISO certification is based on quality management principles including an organization’s strong customer focus, motivation and commitment of top management, their process approach, and continual improvement review. The goal is to ensure customers receive consistently reliable quality products and services. The 2015 certification highlights key changes from the 2008 to the 2015 version which include:

- A stronger focus on risk management and customer satisfaction

- More emphasis on leadership and commitment

- Fewer prescriptive requirements

- More requirements on communication and strategic alignment

- Formal introduction of ‘interested parties’

Haws has been ISO 9001 certified since 1995 and continues to actively aspire to quality expectations for maximized customer experience.

For more information on Haws, visit www.Hawsco.com.