[First seen in ISHN Magazine June 2018]

Introduce the flushing fluid at the inner corner of the eye

An injury can change life in an instant. According to the National Safety Council, occupational injuries occur every seven seconds in the United States. Luckily, through the years, stringent regulation and a growing concern for the health and well-being of employees has led to advancements in processes, safety procedures, and first aid protocols to treat the injured. This movement has had a profound impact on emergency equipment, including the eyewash industry.

In the early 1900s, it was said that a well-known energy company created the first emergency eyewash by taking two bubbler heads from drinking fountains and mounting them on opposite sides of a sink facing each other with plumbing run to both of the heads (see photo). When activated, the water streams formed a double arch that directed water from the outer perimeter of the sink to the center. An injured victim would place their face into the double streams and irrigate both eyes simultaneously. It was a great concept and one that took the safety industry to a new level over the subsequent years.

Yet, as medical advancements continued to evolve, the eye irrigation process in emergency situations did not quite follow suite. Irrigating with water streams that contact the eye at its outer corner, or canthus, and flow inward toward the nose is diametrically opposed to the way medical professionals irrigate eyes.

Think about how you use eye drops. The general practice is to tilt the head back and place the dropper near the inner corner for the drops to drain to the outside of the eye and down the outside of your cheek.

The Lacrimal System

To comprehend the logic behind how the medical communitytreats eye contamination situations you first should understand the eye’s lacrimal system. The human eye is equipped with an automatic lubricating and cleansing mechanism, called the lacrimal system (see illustration). It consists of the lacrimal gland which produces tears, the ducts that channel tears from the lacrimal gland to the ocular surface, and the lacrimal puncta which are drains that channel excess fluids out of the ocular surface.

Importantly, the lacrimal puncta drain excess fluids directly into the nasal cavity. This process is the reason why your nose runs when you cry.

The eyelid also plays a key role. As we blink, the eyelid wipes the cornea pushing contaminants and excess fluids toward the lacrimal puncta – or the ocular surface’s drains.

If a hazardous substance is introduced into the eye, nature’s own cleansing mechanism can serve to force the contaminant into the nasal cavity, where it can be breathed into the lungs or swallowed.

Eye irrigation: The medically consistent way

The medical profession teaches and practices irrigating eyes by introducing the flushing fluid at the inner corner of the eye – adjacent to the nose – and letting it run across the eye to the outer edge. In effect, irrigation is performed by moving the fluid away from the lacrimal puncta. This is opposite the flow direction of traditional eyewash products that flow water from the outside-in, pushing contaminants toward the inner corners of the eyes where these susceptible tear ducts, glands and canals are located. Pushing contaminants toward the nose not only risks introducing them into the nasal cavity, but also can allow the same contaminant to be introduced into the other eye.

The ideal method of irrigating eyes in any use is by using products that mirror approved medical protocols. Eyewash streams that are inverted contact the eyes at the inner canthus, or corner, adjacent to the bridge of the nose. Contaminants are thus swept away from the lacrimal system to the outside of the eye where gravity takes over and runs them into the eyewash bowl (see image). This added protection to valuable internal organs helps reduce unnecessary exacerbation of injuries.

Consistent laminar flow for victim comfort

Additionally, the use of laminar flow design in the eyewash streams is another medical recommendation. A laminar flow is one in which there is an absence of turbulence, because the stream is “built” in layers. Turbulence or inconsistencies in the flow stream can strike the eye as a change in total pressure, making the victim much less comfortable during the flushing process and less likely to stay in the water for the required duration. The best approach is to provide an even, comfortable, predictable stream height and circumference, accomplished by using laminar design principles.

Times are changing, as are the protocols and practices of emergency equipment manufacturers. Irrigating eyes in a manner that is consistent with medical procedures provides the ideal situation for a victim from a comfort and effectiveness standpoint in a circumstance that may not be so ideal.

OSHA regulations vary for eyewash flushing & shower drenching Written by: Wesley J. Maertz

Written by: Wesley J. Maertz

The question often comes up as to where OSHA calls out eyewash requirements. Emergency shower and eyewash station equipment needs are referenced in two different types of OSHA regulations. The first is applicable to all general industry or construction facilities that require the installation of emergency shower or eyewash station equipment. The second type is specific to certain industries.

Both regulation types specify where and when emergency eyewash and shower equipment must be available. Neither, however, specifies minimum selection, installation, operation or maintenance requirements. For the answers to these questions, organizations must turn to the American National Standards Institute (ANSI)/ International Safety Equipment Association (ISEA) American National Standard for Emergency Eyewash and Shower Equipment standard, (ANSI/ISEA Z358.1-2014).

General applicable regulations

When working with corrosives, drenching facilities must be readily available according to 29 Code of Federal Regulations (CFR) 1910.151(c) for general industry and 29 CFR 1926.50(g) for construction industry. Both state, “Where the eyes or body of any person may be exposed to injurious corrosive materials, suitable facilities for quick drenching or flushing of the eyes and body shall be provided within the work area for immediate emergency use.” These drenching facilities could include an eyewash, eye/face wash, shower or combination eye/face wash shower depending on the amount of possible exposure. Because OSHA does not clarify the minimum requirements for “suitable facilities,” employers often look to the ANSI/ISEA Z358.1 Standard for Emergency Eyewashes and Shower Equipment for guidance.

Specific industry applicable regulations

There are also industry specific regulations that address emergency drenching requirements. You must be familiar with these specific requirements if they apply to your workplace:

♦ Open Surface Tanks 29 CFR 1910.124(g)(2) and(3):

“An emergency shower and eye-wash station close to the dipping or coating operation. In place of this equipment, you may use a water hose that is at least 4 feet (1.22 m) long and at least 3/4 of an inch (18 mm) thick with a quick-opening valve and carrying a pressure of 25 pounds per square inch (1.62 k/cm2) or less; and at least one basin with a hot-water faucet for every 10 employees who work with such liquids.

♦ Anhydrous Ammonia 29 CFR 1910.111(b)(10)(iii)

“Stationary storage installations shall have an easily accessible shower or a 50-gallon drum of water.”

♦ Powered Industrial Trucks 29 CFR 1910.178(g)(2)

“Facilities shall be provided for flushing and neutralizing spilled electrolyte, for fire protection, for protecting charging apparatus from damage by trucks, and for adequate ventilation for dispersal of fumes from gassing batteries.”

♦ Pulp, Paper, and Paperboard Mills 29 CFR 1910.261(g)(5)

“…A deluge shower and eye fountain shall be provided to flush the skin and eyes to counteract lime or acid burns.”

♦ Telecommunications 29 CFR 1910.268(b)(2)(i)

“…Facilities for quick drenching or flushing of the eyes and body shall be provided unless the storage batteries are of the enclosed type and equipped with explosion proof vents, in which case sealed water rinse or neutralizing packs may be substituted for the quick drenching or flushing facilities. Employees assigned to work with storage batteries shall be instructed in emergency procedures such as dealing with accidental acid spills.”

♦ Formaldehyde 29 CFR 1910.1048(i)(3)

“If there is any possibility that an employee’s eyes may be splashed with solutions containing 0.1 percent or greater formaldehyde, the employer shall provide acceptable eyewash facilities within the immediate work area for emergency use.”

Consensus applicable regulation

ANSI/ISEA Z358.1-2014 is a voluntary national consensus standard that OSHA refers employers to as a recognized source for guidance. It helps users select, install, operate and maintain emergency eye wash and shower equipment. The standard is divided into five sections and each section addresses minimum performance and use requirements, as well as installation, testing procedures, maintenance and training requirements. OSHA often uses ANSI/ISEA Z358.1-2014 as a guide during inspections and may elect to issue penalties based on non-compliance.

To ensure that eyewash stations and showers are always ready when needed, it is important that the requirements for test procedures and maintenance set forth in ANSI/ISEA Z358.1-2014 be followed. The requirements for testing and maintaining eye, eye/face washes and showers are based on the manufacturer’s instructions and ANSI protocols. Generally, the manufacturer’s instructions state that the devices should be inspected tested and the results recorded weekly. Individual owners’ manuals should be looked at for the specific manufacturer’s guidelines.

Determination of a corrosive material

Within the general guidelines, occasionally the question comes up as to whether OSHA requires eyewashes for anything other than injurious corrosive chemicals. In a May 5, 2004 letter of interpretation, OSHA states: “As the standard states, an eyewash and/or safety shower would be required where an employee’s eyes or body could be exposed to injurious corrosive materials. If none of the materials used in this work area is an injurious corrosive (as indicated by the Material Safety Data Sheet (MSDS) for each product), then an emergency eyewash or shower would not be required pursuant to 1910.151(c) and 1926(g)”

Corrosive material is present in many workplaces either by themselves or contained in other materials. It is a good idea to refer to several sources to determine if a chemical is considered a corrosive to OSHA’s definition as it applies to eyewashes.

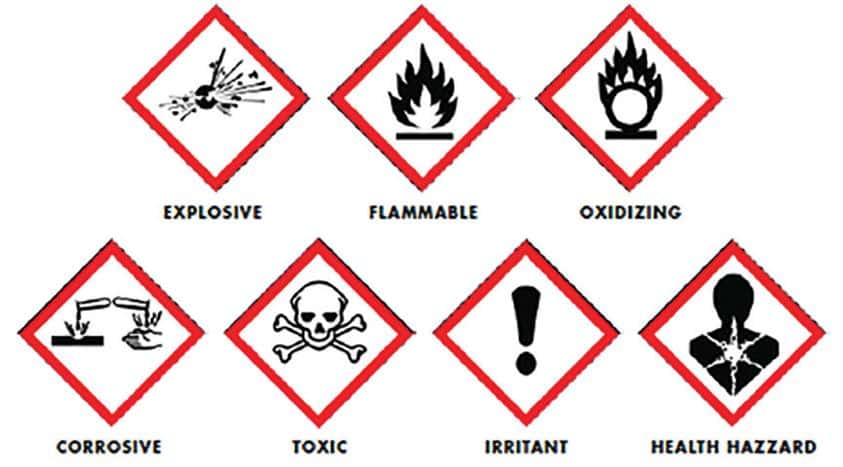

One of the easiest ways to identify if a chemical has corrosive properties is to use OSHA’s Hazard Communication Standard (29 CFR 1910.1200) and the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) as a guide. The universal symbols/pictograms used on labels and containers provide clear indications if a chemical is a corrosive.

Another source to identify if a chemical is corrosive is the Safety Data Sheet (SDS). Section 2 of the SDS will quickly provide the same information found on the shipped container label including the pictogram and precautionary statements. Section 9 of the SDS provides more details about the physical properties of the chemical including pH, which is the measure of how basic or acidic the chemical is on a scale of 0-14. A rating below seven is more acidic and above seven is more basic.

One other source to reference is the NIOSH pocket guide. The pocket guide presents key information such as pH in abbreviated or tabular form for chemicals or substance groupings that are found in the work environment.

View Emergency Equipment Product Solutions here>>

[via ISHN]

Readying Emergency Equipment For The ColdFreezing temperatures can be expected across many parts of the country, sometimes sooner or later in the season than expected. In some areas, exceptionally cold weather will linger indefinitely, while other regions will experience freeze-thaw cycles. If you haven’t already done so, take the time now to ensure that your emergency equipment is ready for the cold weather, no matter how long it’s expected to last.

In the event of an accident, frozen safety equipment that cannot be operated properly, or at all, will turn an emergency into a disaster. It’s precisely this scenario that drives many plant safety managers to inspect and re-inspect their respective emergency equipment environments all the more diligently at this time of year – as well they should. While the best approach to ensuring that safety equipment is always in prime operating condition is with proper product installation, preventative maintenance and routine inspection and testing, there are other methods that are often taken to remedy emergency equipment prone to freezing.

If you live and work in a part of a country in which it’s common to have long periods of time with the temperature staying firmly below freezing, consider these approaches to keeping your emergency equipment operating properly.

The Bury Valve

This approach has been used for years. It involves burying the HAWS MK8A Freeze-protection Bury Valve for the equipment beneath the frost line in the ground. A mechanical linkage connects the buried valve to a mechanical paddle or other method of point-of-use actuation. Also incorporated into this design is a pressure valve, which is located below the frost line as well, that releases all water above the pressure valve when it is not actuated. With this design configuration, all water is left below the frost line until it is needed and remaining water is drained to the ground below the frost line once the equipment is turned off. It is appropriate to test the bury valve, linkage and the pressure valve prior to the onset of winter. If the pressure valve is inoperative – allowing water to stand above the frost line – it may not be noticeable until it’s already too late.

This approach has been used for years. It involves burying the HAWS MK8A Freeze-protection Bury Valve for the equipment beneath the frost line in the ground. A mechanical linkage connects the buried valve to a mechanical paddle or other method of point-of-use actuation. Also incorporated into this design is a pressure valve, which is located below the frost line as well, that releases all water above the pressure valve when it is not actuated. With this design configuration, all water is left below the frost line until it is needed and remaining water is drained to the ground below the frost line once the equipment is turned off. It is appropriate to test the bury valve, linkage and the pressure valve prior to the onset of winter. If the pressure valve is inoperative – allowing water to stand above the frost line – it may not be noticeable until it’s already too late.

Electric Heat-Traced Tape

A popular technology set these days involves the use of electric heat-traced tape wrapped around the pipes and emergency equipment componentry above the frost line. With this alternative, water is available instantaneously, as it is resident in the equipment at all times. While we’ve seen many examples of plants in which standard emergency equipment was modified by the use of heat-traced tape in an effort to make it freeze-proof, it’s not always a recommended approach. The electric heat-traced tape systems use matched components specifically designed for that purpose, but the issue here is that you may have no idea that there’s a freeze problem until someone in dire need tries to use the equipment! Another method that can backfire extraordinarily involves “shade-tree” installations. In this set-up, steam pipes are run close to emergency equipment or emergency equipment supply pipes in an effort to prevent freezing. This presents two potential complications. Hot spots, or scalding hot water at the point of use, or freezing in areas not quite close enough to the warmth, both have the potential to create hidden problems – hidden, that is, until you use the equipment.

A popular technology set these days involves the use of electric heat-traced tape wrapped around the pipes and emergency equipment componentry above the frost line. With this alternative, water is available instantaneously, as it is resident in the equipment at all times. While we’ve seen many examples of plants in which standard emergency equipment was modified by the use of heat-traced tape in an effort to make it freeze-proof, it’s not always a recommended approach. The electric heat-traced tape systems use matched components specifically designed for that purpose, but the issue here is that you may have no idea that there’s a freeze problem until someone in dire need tries to use the equipment! Another method that can backfire extraordinarily involves “shade-tree” installations. In this set-up, steam pipes are run close to emergency equipment or emergency equipment supply pipes in an effort to prevent freezing. This presents two potential complications. Hot spots, or scalding hot water at the point of use, or freezing in areas not quite close enough to the warmth, both have the potential to create hidden problems – hidden, that is, until you use the equipment.

All of that said, heat-traced tape emergency equipment systems remain the most cost-effective answer in areas that experience significant below freezing periods. And in fact, the same heat-tracing technology that makes this approach effective (even if wrapping standard equipment with tape can mask potential problems) can be found on safety equipment that was designed specifically to withstand severe temperatures. The AXION® MSR Freeze-Protected Shower and Eye/Face Wash has safety features including insulation surrounding all piping and an outside jacket designed to prevent freezing. It will operate in temperatures as low as -30°F (-34.4°C). A system such as this effectively eliminates the need for modifications in the colder months – with proper maintenance, it will perform as well in the winter as it does in the summer. An all-weather model like Outdoor Tempered Shower and Eye/Face System is another option. This standard decontamination booth supplies tempered water to the heated shower and eye/face wash no matter how cold it gets outside.

What about parts of the country where prolonged periods of freezing are unlikely, but the occasional snap freeze is a likelihood? In that case, there is a range of anti-freeze valves available to suit varying equipment. These valves, each using a variety of different technologies, turn on a trickle of water during a snap freeze to minimize the possibility of freezing. For example, the Freeze Protection Bleed Valve is a fully engineered freeze-protection valve constructed of a single piece of brass. The automatic thermal actuator bleed valve opens when water temperatures drop below 35°F (1.7°C). It closes completely when the water temperature is above 42°F (5.6°C).

Products in this category are clearly aimed at snap-freeze environments only, due to both water waste with prolonged use and the possibility of pooling and then freezing in many applications. While there is no way of knowing what winter has in store this or any year, failure to prepare can mean significant problems in the event of an emergency. Maintain routine inspections and testing on your safety equipment, and consider alternatives that will ensure your plant’s ability to withstand freeze temperatures – just in case. As with many things, better safe than sorry.

More information on our full range of freeze-resistant equipment.

Download our white paper here>>

AXION Advantage® Upgrade System: 3x Award Winner!

2014 was a successful year for Haws’ AXION Advantage Upgrade Systems! These systems offer safety professionals a medically superior response for upgrading existing emergency equipment.

The AXION® MSR design and technology improves existing emergency equipment with the optimal victim comfort system while maintaining ANSI compliance.

Your facility will have the tools to upgrade older Haws products, replace ineffective products and test for continued ANSI compliance. Each system includes: an AXION MSR eye/face wash or and AXION MSR eye/face wash and showerhead, connecting hardware options and accessories, ANSI eyewash testing gauge and tape measure, complete install instructions, and ANSI Z358.1 compliance and testing guidelines. Upgrading to the Advantage system is easy; simply remove the existing head, select one of the supplied connectors, and attach the AXION Advantage head.

2014 ISHN Readers’ Choice Award

2014 OH&S-Canada’s Readers’ Choice Award

2014 ASSE Safety Expo Attendee’s Choice Award

AXION Advantage™: New Product of the Year2013 and 2014 have been great years as we launched various products including the Model 1900 Bottle Filler, the 9400 Steam Water Heat Exchanger, and the AXION Advantage™ System which have all received strong recognition within the industry. The AXION Advantage™ system offers health and safety professionals a medically superior response for upgrading existing emergency eyewash and shower equipment while exceeding ANSI compliance. With four Advantage kits providing the necessary pieces to convert 80% of existing eyewashes and showers, facilities will have the tools to upgrade older Haws® products, replace ineffective products and test for continued ANSI compliance.

Since it’s launch, AXION® MSR products new product has received numerous award for its ingenuity and ability. In fact, this new AXION Advantage™ System has recently received several occupational safety awards including the 2014 ISHN Readers’ Choice Award, the 2014 American Society of Safety Engineers – Safety Show’s Attendee Choice Award, the ISHN New Product of the Year Award, and the OH&S New Product of the Year Award. To learn about more of our innovative products, visit our Smart Innovation pages.