Freezing temperatures can be expected across many parts of the country, sometimes sooner or later in the season than expected. In some areas, exceptionally cold weather will linger indefinitely, while other regions will experience freeze-thaw cycles. If you haven’t already done so, take the time now to ensure that your emergency equipment is ready for the cold weather, no matter how long it’s expected to last.

In the event of an accident, frozen safety equipment that cannot be operated properly, or at all, will turn an emergency into a disaster. It’s precisely this scenario that drives many plant safety managers to inspect and re-inspect their respective emergency equipment environments all the more diligently at this time of year – as well they should. While the best approach to ensuring that safety equipment is always in prime operating condition is with proper product installation, preventative maintenance and routine inspection and testing, there are other methods that are often taken to remedy emergency equipment prone to freezing.

If you live and work in a part of a country in which it’s common to have long periods of time with the temperature staying firmly below freezing, consider these approaches to keeping your emergency equipment operating properly.

The Bury Valve

This approach has been used for years. It involves burying the HAWS MK8A Freeze-protection Bury Valve for the equipment beneath the frost line in the ground. A mechanical linkage connects the buried valve to a mechanical paddle or other method of point-of-use actuation. Also incorporated into this design is a pressure valve, which is located below the frost line as well, that releases all water above the pressure valve when it is not actuated. With this design configuration, all water is left below the frost line until it is needed and remaining water is drained to the ground below the frost line once the equipment is turned off. It is appropriate to test the bury valve, linkage and the pressure valve prior to the onset of winter. If the pressure valve is inoperative – allowing water to stand above the frost line – it may not be noticeable until it’s already too late.

This approach has been used for years. It involves burying the HAWS MK8A Freeze-protection Bury Valve for the equipment beneath the frost line in the ground. A mechanical linkage connects the buried valve to a mechanical paddle or other method of point-of-use actuation. Also incorporated into this design is a pressure valve, which is located below the frost line as well, that releases all water above the pressure valve when it is not actuated. With this design configuration, all water is left below the frost line until it is needed and remaining water is drained to the ground below the frost line once the equipment is turned off. It is appropriate to test the bury valve, linkage and the pressure valve prior to the onset of winter. If the pressure valve is inoperative – allowing water to stand above the frost line – it may not be noticeable until it’s already too late.

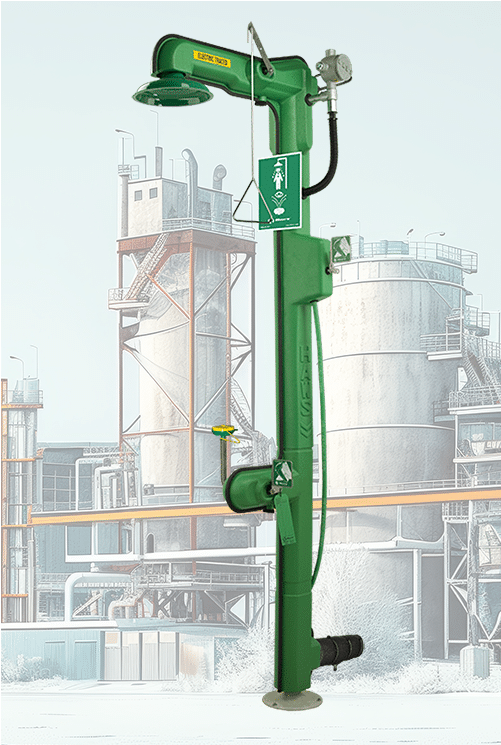

Electric Heat-Traced Tape

A popular technology set these days involves the use of electric heat-traced tape wrapped around the pipes and emergency equipment componentry above the frost line. With this alternative, water is available instantaneously, as it is resident in the equipment at all times. While we’ve seen many examples of plants in which standard emergency equipment was modified by the use of heat-traced tape in an effort to make it freeze-proof, it’s not always a recommended approach. The electric heat-traced tape systems use matched components specifically designed for that purpose, but the issue here is that you may have no idea that there’s a freeze problem until someone in dire need tries to use the equipment! Another method that can backfire extraordinarily involves “shade-tree” installations. In this set-up, steam pipes are run close to emergency equipment or emergency equipment supply pipes in an effort to prevent freezing. This presents two potential complications. Hot spots, or scalding hot water at the point of use, or freezing in areas not quite close enough to the warmth, both have the potential to create hidden problems – hidden, that is, until you use the equipment.

A popular technology set these days involves the use of electric heat-traced tape wrapped around the pipes and emergency equipment componentry above the frost line. With this alternative, water is available instantaneously, as it is resident in the equipment at all times. While we’ve seen many examples of plants in which standard emergency equipment was modified by the use of heat-traced tape in an effort to make it freeze-proof, it’s not always a recommended approach. The electric heat-traced tape systems use matched components specifically designed for that purpose, but the issue here is that you may have no idea that there’s a freeze problem until someone in dire need tries to use the equipment! Another method that can backfire extraordinarily involves “shade-tree” installations. In this set-up, steam pipes are run close to emergency equipment or emergency equipment supply pipes in an effort to prevent freezing. This presents two potential complications. Hot spots, or scalding hot water at the point of use, or freezing in areas not quite close enough to the warmth, both have the potential to create hidden problems – hidden, that is, until you use the equipment.

All of that said, heat-traced tape emergency equipment systems remain the most cost-effective answer in areas that experience significant below freezing periods. And in fact, the same heat-tracing technology that makes this approach effective (even if wrapping standard equipment with tape can mask potential problems) can be found on safety equipment that was designed specifically to withstand severe temperatures. The AXION® MSR Freeze-Protected Shower and Eye/Face Wash has safety features including insulation surrounding all piping and an outside jacket designed to prevent freezing. It will operate in temperatures as low as -30°F (-34.4°C). A system such as this effectively eliminates the need for modifications in the colder months – with proper maintenance, it will perform as well in the winter as it does in the summer. An all-weather model like Outdoor Tempered Shower and Eye/Face System is another option. This standard decontamination booth supplies tempered water to the heated shower and eye/face wash no matter how cold it gets outside.

What about parts of the country where prolonged periods of freezing are unlikely, but the occasional snap freeze is a likelihood? In that case, there is a range of anti-freeze valves available to suit varying equipment. These valves, each using a variety of different technologies, turn on a trickle of water during a snap freeze to minimize the possibility of freezing. For example, the Freeze Protection Bleed Valve is a fully engineered freeze-protection valve constructed of a single piece of brass. The automatic thermal actuator bleed valve opens when water temperatures drop below 35°F (1.7°C). It closes completely when the water temperature is above 42°F (5.6°C).

Products in this category are clearly aimed at snap-freeze environments only, due to both water waste with prolonged use and the possibility of pooling and then freezing in many applications. While there is no way of knowing what winter has in store this or any year, failure to prepare can mean significant problems in the event of an emergency. Maintain routine inspections and testing on your safety equipment, and consider alternatives that will ensure your plant’s ability to withstand freeze temperatures – just in case. As with many things, better safe than sorry.

More information on our full range of freeze-resistant equipment.

Download our white paper here>>