ANSI/ISEA Z358.1 Emergency Shower & Eye Wash Testing

Haws Sightings. We’re (almost) Famous. Whether you’re taking a stroll through Central Park or chasing your kids through The Happiest Place on Earth, most likely you’ve come across a Haws drinking fountain and didn’t even know it. Or maybe you did.

We are everywhere, and below are a few images to prove it.

Around Disneyland

Throughout New York City

Did you know that Haws can create custom drinking fountains? We can customize the color, materials, coating, and much more. A great example is the gold-colored fountain at the Guggenheim Museum, or the shiny coating on the fountain at the One World Trade Center, both shown above. Learn more here

Even on TV

Can you guess the show? Here’s a hint the answer: Netflix’s The OA (season 2, episode 7)

Even our emergency equipment has been spotted on Alcatraz Island.

The next time you’re out, take a look at the fountains in your path. Find a Haws product? Submit it to [email protected] for a social share on our Facebook or Twitter page!

Haws® Attends IFMA & A+A in October Haws® exhibited at the recent International Facility Management Association (IFMA) World Workplace Conference & Expo October 18-20, 2017 in Houston, Texas. The World Workplace expo is an event geared toward learning and relationship-building within the facility management field. Attendees were able to see hundreds of Facility Management toys, tools, and resources from the leading names in FM solutions, including Haws. The attendees were able to see product demonstrations, attend informational sessions, and have one-on-ones with exhibitors. Haws was in a unique position to be the only Emergency Response Equipment and Hydration Products manufacturer at this event.

Haws AG also displayed at the A+A in Dusseldorf Germany. All aspects of safety, security, and health at work were brought together October 17-20, 2017 at the international trade forum that is A+A. Haws was able to present our emergency equipment and safety solutions to a global and highly qualified expert audience of decision-makers.

Haws Corporation expands access in Middle East  Haws – Switzerland announced its expansion into new markets in the Middle East, increasing its investment and presence to come closer to partners in key markets. This new extension will provide immediate access for customers in the region to help Haws better serve their needs and to develop stronger partnerships with local entities.

Haws – Switzerland announced its expansion into new markets in the Middle East, increasing its investment and presence to come closer to partners in key markets. This new extension will provide immediate access for customers in the region to help Haws better serve their needs and to develop stronger partnerships with local entities.

Recently, Haws welcomed two regional sales team members, Sampeep Verma and Michael Alex, as Business Development Managers – Middle East. Mr. Verma and Mr. Alex split territory coverage with specific regions assigned.

“Over the last 30 years, we have made tremendous progress in establishing Haws as a significant player in the EMEA safety equipment marketplace and expanding our reach to local markets. As one of the fastest growing markets globally, Middle East is an important and strategic region to continue our growth plans,” said Urs Weder, Manager Director of Haws – AG.

The Haws team will be showcasing new products and services at the A+A International Trade Fair and Congress in Dusseldorf in October in Hall 7A at Booth F13.

For more information, visit www.Haws.ch or [email protected].

OSHA and ANSI Requirements for Eyewash and Safety Showers

[via LabManager.com]

ANSI standard Z358.1 is detailed in terms of defining what is appropriate for safety showers and eyewash stations.

As lab managers and employees, we know that many inorganic chemicals (such as the mineral acids and alkalis) are corrosive to the skin and eyes. Likewise we are aware that many organic chemicals (such as acid halides, phenols, and so on) are corrosive and often toxic. Yet we Safety Guys are continually shocked by laissez-faire attitudes toward the use and maintenance of basic safety equipment by lab personnel, and the resultant unnecessary injuries.

One extreme example we constantly recall is the tragic UCLA accident just a few years ago, which resulted in a fatality from chemical burns.1 And we recently noticed a post on the American Industrial Hygiene Association pages for Lab Safety Chemical Exposure Incidents, where improper use of an eyewash resulted in a trip to the emergency room.2

The worker was using a fluorescent stain in the cytogenetics lab and felt something splash into his eyes. He was not wearing safety goggles or glasses. (D’oh!) Long story shortened, he flushed his eyes at the nearest eyewash, but they remained irritated and began to swell shut, necessitating a visit to the emergency room. Back at work a few days later, he noticed a coworker using the same eyewash to clean glassware and stainless steel trays, which were left resting in the sink in a cleaning solution. (What?!)

What does OSHA say?

In 29 CFR 1910.151 Medical Services and First Aid, it states that “where the eyes or body of any person may be exposed to injurious corrosive materials, suitable facilities for quick drenching or flushing of the eyes and body shall be provided within the work area for immediate emergency use.”3 OSHA doesn’t provide more specifics regarding what constitutes “suitable” or how “immediate” is defined. So how do we know if we are meeting the intent of the law?

Fortunately, we have the American National Standards Institute (ANSI), and their consensus standard Z358.1, last updated in 2014. This ANSI standard is very detailed in terms of defining what is appropriate for safety showers and eyewash stations. In fact, OSHA uses this reference as a guide when inspecting facilities. So let’s review what is “recommended” for acceptable safety equipment.

Safety shower specs

Begin by checking your facilities for the proper hardware, as recommended by Z358.1. Rest assured that OSHA will, should one or more agents show up for an inspection. For safety showers, the shower head must be capable of flowing 20 gallons per minute (gpm) at 30 psi and producing a 20-inch diameter spray pattern at 60 inches above the surface where the user stands. The center of the sprayhead pattern should be at least 16 inches from any wall, door, or obstruction. It is recommended that the shower head be mounted between 82 and 96 inches off the floor, with the valve no higher than 69 inches.

Eyewash specs

Eyewash stations target just the eyes and therefore have a lower flow requirement. ANSI Z358.1 recommends a flow of 0.4 gpm also at 30 psi. The nozzles should be at least six inches from any obstruction and mounted between 33 and 45 inches above the floor. An eyewash gauge should be used to verify and test the flow pattern.

Requirements for both

Both safety showers and eyewash stations must be able to provide the recommended flow for at least 15 minutes. This usually translates into having the equipment plumbed in with hard connections to the water supply. For example, a quick calculation for the safety shower at 20 gpm yields 300 gallons needed. Self-contained or personal wash devices are allowed, but they are considered supplemental units that can provide immediate flushing while transiting to the permanent fixture.

If the local climate presents potential for freezing conditions, the equipment must be designed to avoid freezing or protected against that situation. Activation valves must open within one second and remain open until intentionally closed or turned off. It goes without saying that these safety devices should be constructed of corrosion-resistant materials.

The 2014 update to Z358.1 added two important criteria. The first is that the requirement for tepid water is now defined as having a temperature of between 60 and 100 degrees Fahrenheit (15 to 37 degrees Celsius). The second change addresses simultaneous operation for combination units. This means that if you have a drench shower combined with an eyewash station, both devices must provide adequate flows and be fully operable at the same time.

Finally and most importantly, consider the location of equipment. We know you have the 10-second rule etched into your brain, as that is the most critical element when it comes to safety showers and eyewashes. This means that travel to the unit should be under 10 seconds for all hazardous areas that need this equipment. This equals about 55 feet. In addition, the drench shower or eyewash must be on the same level as the hazard and have a clear path for travel. We recommend painting or marking the floor area underneath the shower to help keep it clear. Z358.1 also recommends equipment be installed in a brightly lit area and marked with a highly visible safety sign.

Maintenance and training

The last thing you want is to rush to the eyewash or shower, only to be drenched with nasty, sediment-laden water. ANSI recommends flushing all equipment weekly to verify proper flow, and clearing the plumbing of any deposits. If your facility does not have floor drains installed, remember to bring a large, plastic trash can to catch the water. The weekly flushing can also provide a great training opportunity to refresh the operation and travel paths for your employees.

If you want to find out about the ANSI/ISEA Z358.1 significant requirements, attend our free 1-hour webinar on September 21st, 2017.

Register now and become subject matter experts of your emergency eyewash and shower equipment including weekly and annual testing. Request a certificate of attendance after the webinar.

This free webinar will cover:

• ANSI/ISEA Z358.1 significant requirements

• Important 2014 revision highlights

• Compliance best practices

• Live Q&A

WHAT: All You Need to Know About ANSI Z358.1 Webinar

WHEN: September 21, 2017 from 10am-11am PT / 1pm-2pm ET

PRESENTER: Justin Dunn, Product Specialist/Trainer and Samantha Hoch, Marketing Strategist

HOW: Register for free

Attendees will receive these complimentary materials after the webinar:

• OSHA white paper

• Weekly and Annual ANSI Checklist

• Access to On-Demand Webinar

REGISTER NOW>>

References

1. “tert-Butyllithium Claims Fellow Chemist at UCLA,” Chemistry Blog, January 19, 2009, http://www.chemistry-blog.com/2009/01/20/tert-butyllithium-claims-fellow-chemist-at-ucla/.

2. “Lab Safety Chemical Exposures Incidents,” American Industrial Hygiene Association, https://www.aiha.org/get-involved/VolunteerGroups/LabHSCommittee/Incident%20Pages/Lab-Safety-Chemical-Exposures-Incidents.aspx.

3. “Medical Services and First Aid,” US Department of Labor, Occupational Health and Safety Administration, https://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=STANDARDS&p_id=9806.

Reduction of Lead in Drinking Water and the Installation of Emergency Eyewashes and Showers  SAFE DRINKING WATER ACT SUMMARY

SAFE DRINKING WATER ACT SUMMARY

Since 1986, the Safe Drinking Water Act (“SDWA” or “the Act”) has prohibited the use of certain items that are not lead free, and since 1996 the Act has made it unlawful for anyone to introduce into commerce items that are not lead free.

Section 1417(a)(1) prohibits the “use of any pipe, any pipe or plumbing fitting or fixture, any solder, or any flux, after June 1986, in the installation or repair of (i) any public water system; or (ii) any plumbing in a residential or non-residential facility providing water for human consumption, that is not lead free” as defined in Section 1417(d).

The 2011 Reduction of Lead in Drinking Water Act revised Section 1417 to:

(1) Redefine lead free in SDWA Section 1417(d) to:

- Lower the maximum lead content of the wetted surfaces of plumbing products such as pipes, pipe fittings, plumbing fittings and fixtures from 8.0% to a weighted average of 0.25%;

- Establish a statutory method for the calculation of lead content; and

- Eliminate the requirement that lead free products be in compliance with voluntary standards established in accordance with SDWA 1417(e) for leaching of lead from new plumbing fittings and fixtures.

(2) Create exemptions in SDWA Section 1417(a)(4) from the prohibitions on the use or introduction into commerce for:

- “pipes, pipe fittings, plumbing fittings or fixtures, including backflow preventers, that are used exclusively for nonpotable services such as manufacturing, industrial processing, irrigation, outdoor watering, or any other uses where the water is not anticipated to be used for human consumption;” (SDWA 1417(a)(4)(A))

- “toilets, bidets, urinals, fill valves, flushometer valves, tub fillers, shower valves, service saddles, or water distribution main gate valves that are 2 inches in diameter or larger.” (SDWA 1417(a)(4)(B))

The amendments became effective on January 4, 2014.

SDWA AND EMERGENCY EQUIPMENT EXEMPTION

Emergency eyewash devices or emergency drench showers are not subject to the prohibitions in Section 1417 of the Safe Drinking Water Act whether they are separate devices or single units that combine an emergency drench shower and emergency eyewash devices, either with or without dedicated piping. Section 1417(a)(4)(A) exempts pipes, fittings, and fixtures used exclusively for nonpotable services. As explained in the EPA’s Summary of the Reduction of Lead in Drinking Water Act and Frequently Asked Questions, the EPA interprets the phrase “potable services” in this context to be services or applications that provide water suitable for human ingestion, e.g. drinking, teeth brushing, food preparation, dishwashing, maintaining oral hygiene.

An eyewash device and its dedicated piping would be exempt under Section 1417(a)(4)(A) because it is used exclusively for services that are considered nonpotable for purposes of Section 1417 of SDWA – eye washing. Similarly, showering is a nonpotable service for the purpose of interpreting Section 1417. In addition, “shower valves” are exempt under Section 1417 (a)(4)(B). Therefore, an emergency drench shower and any dedicated piping would not be subject to the prohibitions in Section 1417 of SDWA.

Haws exhibits at ASSE and SHE In the month of June, Haws exhibited at two safety expo’s: Safety and Health Expo in London and the ASSE (American Society of Safety Engineers) Expo in Denver, Colorado. Below are some photos highlighting our displays at the successful shows.

Six Emergency Response Habits Employees Need to Develop [via OHS Online]

Six Emergency Response Habits Employees Need to Develop

Six Emergency Response Habits Employees Need to Develop

Employees need to refresh their training and have drills regularly so they will be able to rely on both their knowledge and their experience when emergencies happen.

By Karen D. Hamel Jul 01, 2017

If safety glasses, ear plugs, and steel-toed shoes are required in a production area, most employees who work there every day will eventually get into the habit of wearing them—especially when they receive coaching and positive reinforcement for remembering them. When the same start-up procedure is used at the beginning of the shift every day, it will become habitual, too.

Developing good safety habits can help reduce the chance of injuries. But what happens when there is an emergency or something out of the normal happens? Employees need to be just as prepared for the unexpected as they are for routine operations.

Training employees on the types of emergencies that could happen at or around the facility and what their role is during those emergencies are essential first steps in preparing them to respond appropriately. In some cases, the training may be even be required by OSHA regulations. Drills help everyone to apply what they have learned and actually walk through the response process so that it becomes familiar. The trick is having drills often enough that employees can develop emergency response habits.

Many professional responders agree that when there is an emergency, people’s actions don’t rise to the occasion—they fall back to their highest level of training. This happens because it is what they know, which makes them comfortable with the actions they need to take. That’s one of the reasons why even the most seasoned responders train and drill regularly, so that they know what they are going to do, which makes them ready to act instinctively when the need arises.

Given that even professional responders continually train and drill so that they will be prepared to act, it is wrong to assume that employees will instinctively know what to do when there is an emergency. Just like the firefighters, hazmat team, ambulance crew, or anyone else who may be called for assistance, employees need to refresh their training and have drills regularly so that they will be able to rely on both their knowledge and their experience when emergencies happen.

While it is probably not realistic to train every employee to be a contingency planner who is prepared for any time of emergency that could ever happen, each employee needs to specifically know what they are expected to do during different types of emergencies. Here are a few of the basic emergency response habits every employee can develop.

Exit Routes

Some facilities have multiple types of alarms, but for many facilities, an alarm means that something is wrong and everyone should evacuate. Each employee should know where the exit routes are and where the closest exit is. In addition, they should also be able to leave the building at least two different ways.

Be sure that evacuation drills allow employees to practice using both primary and alternative routes so that they are less likely to panic if they aren’t able to use their primary route in an emergency. Employees also should know where to go after they leave the building and whom to report to after they have evacuated.

Chemical Splashes

Under OSHA’s Hazard Communication Standard, hazardous chemical containers need to be properly labeled. The information on the label provides basic information about a chemical’s hazard. But when an employee has been splashed or unsafely exposed to a hazardous chemical, Safety Data Sheets (SDS) can provide more details to better help the affected employee. Knowing where to locate SDS and how to quickly find the one that is needed allows faster response and can lessen the extent of an injury.

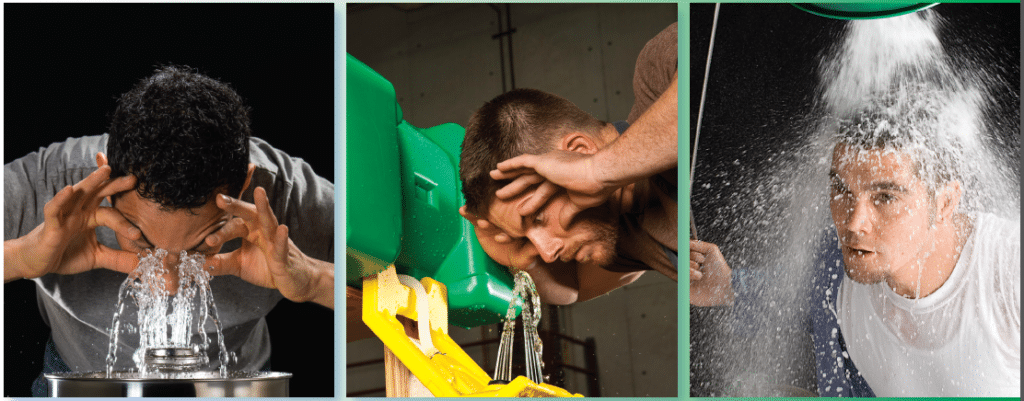

Eyewash Stations and Drench Showers

In areas where corrosive chemicals are used, knowing how to get to eyewash stations and drench showers quickly can literally mean the difference between a first aid incident and a recordable injury with a long recovery time. Try blindfolding employees to see whether they can reach the nearest eyewash or drench shower in less than 10 seconds.

Fire Extinguishers

Most building codes require fire extinguishers; because they need to be checked monthly, most are fully charged and ready to use. However, whether or not employees should actually use them is sometimes a debate. Some facilities develop “do not use” policies because they feel that having an employee attempt to put out an incipient fire with an extinguisher is too big of a risk. Instead, they want their employees to pull the fire alarm and exit the building.

For facilities that do not have this type of policy, annual fire extinguisher drills can help them to remember to pull, aim, squeeze, and sweep. Be sure that these drills also include instruction on exiting the building if they have exhausted an extinguisher but have failed to put out the fire.

Spill Response

Most spills that happen in fixed facilities are small and can be safely cleaned up by employees in the immediate area. OSHA calls these “incidental spills.” When a spill creates an unsafe atmosphere or threatens the health of employees, it is most likely an “emergency spill” and needs to be cleaned up by employees who have been trained to OSHA’s Hazardous Waste Operations and Emergency Response (HAZWOPER) Standard.

All employees need to be taught how to quickly determine whether they are capable of cleaning up a spill or need to call in trained emergency spill responders. Volume, location, chemical properties, and levels of training are all factors that need to be taken into consideration when training employees how to determine whether a spill is incidental.

Injury Response and Reporting

Facilities that are not located in close proximity to hospitals or infirmaries need to have employees who are trained to administer first aid. While it is not necessary for every employee to receive first aid training, it is important for every employee to know what to do when someone is injured. At a minimum, every employee should know whom to report an injury to, as well as the process that will be used to investigate the root cause of an incident. Even elementary skills such as being able to retrieve the first aid kit or AED, or being able to meet the ambulance at the door and direct them to an injured employee, are helpful.

Few people ever reach the point where responding to emergencies is as instinctive as tying their shoes. But without regular emergency training and drills, response actions will never become familiar, let alone become habits. The more comfortable employees are with their roles in emergency response, the more likely they will be to follow established plans and avoid injuries.

This article originally appeared in the July 2017 issue of Occupational Health & Safety.

A Legacy of Innovation By Stephanie Kilroy

One hundred and ten years ago, Luther Haws created a drinking solution that would become the first product for Haws Sanitary Drinking Faucet Company. Luther saw children drinking from a common cup on a playground at a public school; as a result, he invented a bubblerhead drinking faucet. This innovation sparked what would eventually be an enterprise business employing over two hundred employees globally.

The product innovation initiated by Luther Haws continued across generations. In the 1940’s, maintenance men from an oil refinery in Richmond, CA would come by the Haws plant in Berkeley to shop for parts: round ball type bubblers, flow regulator and fittings. After inquiring about the need for these spare parts instead of completed models, Haws was informed that these parts were being used to build equipment to flush eyes. Employees at Haws sought to understand the needs of the customer and began making these emergency eyewashes and drench showers for them. This was the unofficial launch of Haws emergency equipment products; the earliest drawings date back to 1949.

Haws employees have great pride in our innovative spirit which continues to thrive in 2017. One of Haws’ recent accomplishments has been the development of a professionalized R&D department. Under the leadership of Michael Joyer, new ideas are being generated regularly with many of these innovative ideas already introduced to the market. For example, the 7501T Tempered, Gravity-Fed, Portable Eyewash was one of the first products borne out of the R&D lab.

Haws employees have great pride in our innovative spirit which continues to thrive in 2017. One of Haws’ recent accomplishments has been the development of a professionalized R&D department. Under the leadership of Michael Joyer, new ideas are being generated regularly with many of these innovative ideas already introduced to the market. For example, the 7501T Tempered, Gravity-Fed, Portable Eyewash was one of the first products borne out of the R&D lab.

Haws is also called to innovate, not simply with new products, but in the way we do business. We are a stable, multigenerational family company, we are learning to change and improve processes. Haws employees are looking for internal efficiencies and ways in which we can best meet the needs of our customers. Recently, the Production team has developed a cross-training initiative aimed at flexing team work assignments to serve business demands.

These types of cross-functional, support teams are increasing and delivering impactful deliverables. In Q1, Marketing and Customer Service launched a Live Chat program on the Haws website to provide immediate access to customers. The Haws China website launch is another joint effort initiative intended to widen our global marketplace coverage. Launched in Q2 2017, this was a true collaboration between the Haws China and Corporate Marketing teams. And these are just a few of the examples of all the successful small and large activities that are helping drive change to redefine how we innovate, how we grow and how we foster a culture that is rewarding for all.

One hundred and ten years later, Haws continues our commitment to inventing, designing and manufacturing hydration products as well as standardized and customized emergency response products. With more than 8,000 distribution locations and 200 employees worldwide, we continually focus on quality, service, reliability and complete solution support. Headquartered in Sparks, Nevada, USA, Haws is globally represented with locations in Switzerland, Singapore, China, India, and Brazil. For more information on Haws, visit www.Hawsco.com.

TRADESHOW: Join us @ Safety & Health Expo in London. Your entry is on us! Haws Switzerland  AG invites you to join us at the Safety & Health Expo June 20-22, 2017 at Excel London.

AG invites you to join us at the Safety & Health Expo June 20-22, 2017 at Excel London.

Safety & Health Expo, organized by UBM EMEA, is the UK’s leading global health and safety event, providing visitors with CPD accredited education, the latest health and safety products and services, valuable networking opportunities and much more.

Are you interested in attending? If so, we’d like to offer you a free badge to the expo! Click on this link and fill out your information.

Don’t forget to stop by our Stand No. M215 to learn more about our various product offerings including our EN and ANSI compliant emergency eyewash and shower equipment.

We hope to see you there!

Haws AG- Switzerland provides tempering solution for Belgium facility Haws AG – Switzerland recently hosted an onsite Factory Acceptance Test (FAT) for a large oil & gas company from Belgium. Testing was held onsite in the Burgdorf office with the Haws engineering and production teams as well as the Belgium distributor, Vandeputte – Safety Experts, and the customer project team members. Testing included electrical, alarms, tempering, and system functionality validation. All (10) of the customized model 8721 units passed the stringent requirements and are en route to their new home in Belgium.

Emergency Response is a Matter of Time Written and published by: Ryan Pfund, Occupational Health & Safety Magazine

January 1, 2017

In an emergency, the faster the response, the better the outcome.

An emergency safety plan that anticipates every work site emergency and improves emergency response time is every facility manager’s and employee’s best protection. It’s difficult to think clearly and logically in a crisis, so having a well-orchestrated strategy in place that can be properly and quickly executed by employees makes all the difference.

When an employee at a work site is exposed to hazardous chemicals, taking these pre-emptive actions will help ensure the most positive outcome:

1) Providing a well-organized work site equipped with easily accessible eyewashes or drench showers

2) Minimizing the length of response time for accessing emergency equipment and drenching the employee’s affected area(s)

3) Employing emergency signaling systems to ensure immediate help is on the way, including emergency medical care

Time is clearly of the essence in stopping the exposure, alleviating discomfort and pain, and preventing further or permanent facial and bodily damage. For example, an eyewash or drench shower must be located within 10 seconds of the hazard, so the injured person can quickly and easily reach the plumbed fixture to immediately drench affected areas. Time is also a factor in the length of time one stays in the flushing fluid, which should be for a full 15 minutes as required by the ANSI/ISEA Z358.1 standard. Reaction time of emergency response personnel to swiftly gain access to the injured party is also critical in halting further injury and getting the exposed user proper medical attention.

For proper and expedient execution of a safety plan, it’s important to carefully review with employees the basics on placing and using emergency safety equipment and what to do following a co-worker’s accident. Consider these elements of emergency planning and response preparedness:

Why Use Emergency Fixtures?

Emergency safety showers and eyewashes prevent permanent eye and skin damage from chemical burns or foreign substances generated by grinding, hammering, chipping, testing, pouring, storing, transporting, and disposing operations. Proper selection, placement, and maintenance of this equipment will minimize risk of exposure while reducing the chances of catastrophic employee health impacts, work productivity, or even legal costs for the facility.

Eyewash and drench shower fixtures are placed throughout hazardous environments wherever there is risk of exposure to eye or bodily contaminants. Environments also may include inclement conditions such as heat, freezing, and airborne chemicals. Plumbed, portable, and self contained/stand-alone units should be matched to work site needs.

Where Are Proper Locations for Placement?

Each unit should be stationed close to a hazard, easily seen, and in immediate good working order. It is highly recommended to conduct a walk-through of the facility with a health or safety expert to determine proper locations and types of fixtures for each location.

Here are some fundamental placement guidelines:

- Emergency shower fixtures must be within 55 feet of a potential hazard and must take no more

than 10 seconds to access. In addition, the path to the fixture must not be obstructed by debris or other hazards that could interfere with the fixture’s use.

than 10 seconds to access. In addition, the path to the fixture must not be obstructed by debris or other hazards that could interfere with the fixture’s use.

- The area around the fixture should be well lit to optimize visibility, and each fixture should be identified with a highly visible sign.

- If a potential chemical spill in an area is likely to affect multiple workers, a sufficient number of fixtures should be made available.

- If the worker’s ability to walk or move could be impacted by the chemical exposure, the fixture should be placed closer to the worker.

- The equipment must be on the same level on which the user is working.

When Is an Eyewash Needed vs. a Drench Shower?

After potential hazards throughout a work site are identified, consider how the types of fixtures can best address the risk:

- Emergency eyewash stations

- effective for spills, splashes, dust, or debris likely to affect only the eyes

- provides a controlled flow of water to both eyes simultaneously

- delivers an uninterrupted, 15-minute supply of tepid water; plumbed units can supply a greater volume of water available to the user—between 7.5 and 19.0 liters (2.0 and 5.0 gallons) per minute

- Emergency eye/face wash stations

- used when the entire face is at risk from spills, splashes, dust, and debris

- irrigates the eyes and face simultaneously

- provides a large distribution pattern of water (minimum 11.4 lpm/3.0 gpm) to effectively rinse the entire face

- Drench showers

- used when larger areas of the body are at risk

- flushes a larger portion of the body but is not appropriate for the eyes (a combination eyewash and drench shower may be used to simultaneously flush the eyes and rinse larger areas of the body)

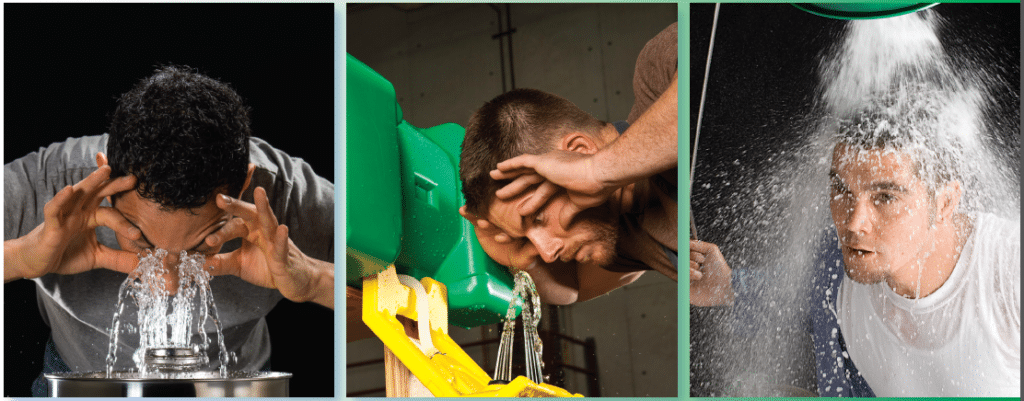

Drench showers work by simply pulling down on the drench shower handle while standing directly underneath the shower head. New technology will effectively drench the entire body without needing to move around in the spray pattern. Eye and eye/face washes work by pushing a handle or lifting a bowl cover. The face is then positioned directly in the flushing fluid, while the user holds their eyelids open with their fingers. The user should roll his or her eyes around while positioned directly in the eyewash streams to effectively rinse the entire eye. Ensuring employees are trained on the proper and expeditious use of equipment is essential to worker safety.

For both eyewashes and drench showers, it’s essential to have direct and on-demand access to tepid water—per ANSI requirements—to encourage a full and effective flush of the affected area. ANSI Z358.1-2014 stipulates that an injured worker remains beneath the drench shower and/or flush his eyes/face for a minimum of 15 minutes to increase the likelihood of a complete and successful treatment and minimize the possibility of inadvertently spreading hazardous material to other areas.

What Is the Response Protocol After Someone Uses an Emergency Fixture?

Each employee should be trained on what action to take in assisting the affected employee(s) and how to report emergencies to emergency medical personnel. To help with the notification process, it is essential to have the ability to immediately send a clearly recognizable signal of an emergency that notifies others to help and/or send help. Using new signaling technology that works in tandem with each emergency fixture will quickly notify on-site workers and medical personnel and expedite the emergency response and recovery process.

Using a signaling system along with emergency fixtures is important because of common hindrances in the work site to alerting others. For example, industrial work environments don’t always allow for several people to be in the immediate area of a work site hazard. One person could be working outside alone or only a few people could be working within an expansive area or during third shift. These situations can affect co-workers’ capacities to be aware that an emergency is even happening and, therefore, impede their abilities to help the injured get follow-up medical care.

Another obstacle in providing immediate emergency response and post-medical care is the time it takes for emergency responders to be dispatched to a work site. According to NEDARC (the National EMSC Data Analysis Resource Center), the average emergency medical services response time in the United States is 9.4 minutes. The sooner EMS teams are alerted, the sooner they can attend to a work site emergency.

While all employees should be trained on what to do if a co-worker has been exposed to hazardous chemicals, they should not be relied upon to completely abate the emergency. It’s best to ensure proper medical response is provided in such a dynamic and emergent situation, and an emergency signaling system is a clear method to communicate when and where medical assistance is needed.

How Do Emergency Signaling Systems Work?

Signaling devices are connected to emergency showers and eyewashes. Upon activation of the fixtures, the signaling devices are automatically triggered to turn on a highly visible flashing light and a loud sound designed to cut through ambient noise. The signaling systems call others to help, draw attention to the precise location of need, alert management to contact first responders, and provide remote monitoring of safety equipment.

Installing an emergency signaling system is a much faster and efficient way to alert those in the immediate area, as well as managers or safety personnel in other locations, that an employee is in need of help. It’s important to make sure various alarms in the facility are highly distinctive and recognized by all employees as a signal to response actions identified in your plan.

The first seconds following eye and skin exposure are absolutely critical to minimizing worker injury, which is always the main goal of any worker safety program. Instituting a well-devised safety plan, having access to proper emergency equipment, and providing a reliable emergency signaling system can expedite response and improve the outcome of the emergency.

Six Emergency Response Habits Employees Need to Develop

Six Emergency Response Habits Employees Need to Develop

Haws employees have great pride in our innovative spirit which continues to thrive in 2017. One of Haws’ recent accomplishments has been the development of a professionalized R&D department. Under the leadership of Michael Joyer, new ideas are being generated regularly with many of these innovative ideas already introduced to the market. For example, the

Haws employees have great pride in our innovative spirit which continues to thrive in 2017. One of Haws’ recent accomplishments has been the development of a professionalized R&D department. Under the leadership of Michael Joyer, new ideas are being generated regularly with many of these innovative ideas already introduced to the market. For example, the