Have emergency showers and eyewashes in your facility? Do you know if they are compliant with the most recent ISEA/ANSI Z358.1- 2014 Standard?

We are offering you a COMPLIMENTARY full day site inspection of you existing emergency response equipment, regardless of brand. And that’s not even the best part…

Once the physical equipment inspection is completed, we’ll provide you a full detailed report which will include the status of each piece of equipment, an executive summary, and…

A full recommendation report detailing what we recommend you need to do to upgrade your equipment to ensure ANSI compliance!

As if that’s not enough, all you have to do to take advantage of this offering is fill out a form! Then, a Haws Representative in your area will reach out to you to schedule the site visit.

Now, how in the world to you pass up an opportunity like this?? You just don’t. So go ahead and hit the pretty green button below to get started! (Restrictions apply)

Access is everything: Eyewash stations & showers must be ready when neededWritten by Sally Smart

Sally J. Smart is a Technical Safety Specialist for Grainger. She is a Board Certified Safety Professional® (CSP) and a Qualified Safety Sales Professional (QSSP). Sally is OSHA – 30-hour trained for both Construction and General Industry and is an OSHA Authorized Outreach Trainer for General Industry.

When working with corrosives, drenching facilities should be readily available. According to OSHA’s Medical and First Aid Standard 29 Code of Federal Regulations (CFR) 1910.151(c) “Where the eyes or body of any person may be exposed to injurious corrosive materials, suitable facilities for quick drenching or flushing of the eyes and body shall be provided within the work area for immediate emergency use.” These drenching facilities could include an eyewash, eye/face wash, shower or combination eye/face wash shower depending on the amount of possible exposure.

Since OSHA does not clarify what the minimum requirements for “suitable facilities” are, employers look to the voluntary American National Standards Institute (ANSI) Z358.1-2014 Standard for Emergency Eyewashes and Shower Equipment for guidance. ANSI Z358.1-2014 helps users select and install proper emergency equipment to meet OSHA requirements. Also, OSHA often uses ANSI Z358.1 as a guide during inspections and may elect to issue penalties for those found not to be in compliance.

ANSI Z358.1-2014 Requirements

To ensure that eyewash stations and showers are always ready when needed, it is important that the requirements for test procedures and maintenance set forth in Z358.1-2014 be followed.

ANSI Z358.1-2014 is divided into five sections and each section addresses how the equipment should perform, as well as testing procedures for ensuring proper operation, installation, maintenance and training.

The requirements for testing and maintaining eye, eye/face washes and showers are based on the manufacturer’s instructions and ANSI protocols. Generally, the manufacturer’s instructions state that the units should be inspected and tested and the results recorded weekly. Individual owner manuals should be reviewed for the specific manufacturer’s guidelines.

Plumbed and Self-Contained Emergency Showers, Eyewash Equipment, Eye/Face Wash Equipment and Combination Units Performance and Maintenance Criteria:

- Valve should easily activate in a second or less and remain open on its own until it is intentionally turned off

- If a potential for freezing exists, product specifically designed to avoid freezing should be used

- Plumbed units should be activated on a weekly basis long enough to ensure that flushing fluid is provided

- • Plumbed and self-contained showers must maintain a minimum flushing fluid of 20 gallons per minute (GPM) at 30 pounds per square inch (PSI) for 15 minutes

- Plumbed and Self-Contained Eyewash Equipment must maintain a minimum flushing fluid of 0.4 GPM at 30 psi for 15 minutes

- Eye/Face wash equipment must maintain a minimum flushing fluid of 3 GPM at 30 PSI for 15 minutes

- Determine that flushing fluid is tepid (between 60 – 100°F)

- Determine that flushing fluid is dispersed throughout the required pattern

- Showers, eyewashes, eye/face washes, and drench hoses all can be utilized in combination units and the requirements of each of these types of product categories must be met when utilized with other categories of emergency equipment

- Self-contained units should be visually inspected and needed fluid replacement determined

Supplemental Equipment

- Supplemental equipment is intended for immediate use and must be followed up by the usage of emergency product that can provide a minimum of 15 minutes of flushing fluid continuously

- Personal eyewash units and drench hoses are considered supplemental equipment

Annual inspections

Each year emergency products must be inspected to ensure they comply per the ANSI standard. While a fixture may be certified to meet the ANSI standard, once installed, it is important to make sure it is installed according to the standard’s requirements.

Weekly checklist

- Initial and date in the corresponding box verifying that the emergency eyewash/shower is checked weekly to ensure:

- Equipment is installed within 10 seconds from the hazard and on the same plane as the hazard

- Pathway is clear of obstructions

- Equipment is activated to ensure compliant operation and to clear any sediment

- Equipment is free of broken or missing parts

- Equipment is protected against freezing

- User is protected from scalding water

Save critical seconds

Always inspect and test emergency eyewashes and showers if there is any doubt about their dependability. Identify problems or concerns and establish a regular maintenance program. Consult the manufacturers’ operating manual and ANSI Z358.1-2014 for guidance on test procedures, maintenance, operation and training.

Inspection, testing and maintenance of the emergency eyewash/shower equipment helps ensure that it will function properly when needed. Studies show that the seconds immediately following an eye or body injury caused by a corrosive are often critical to minimize damage.

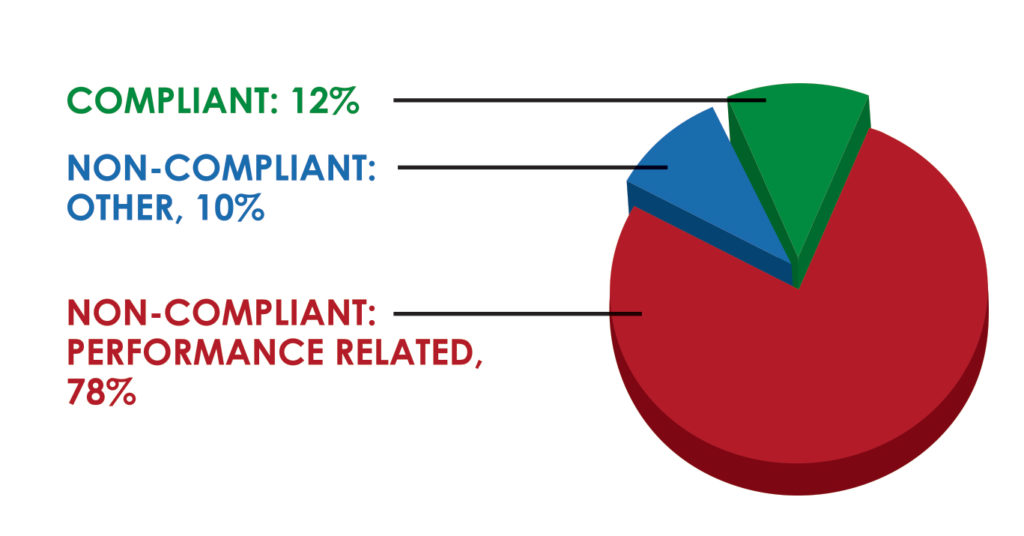

HAWS EMERGENCY SHOWER AND EYEWASH SITE SURVEY PROGRAM

As the industry leader, Haws can help bring awareness to the hidden dangers of inadequate emergency response by providing your facility the opportunity to receive a complimentary ANSI compliance emergency shower and eye/face wash survey. The onsite review includes a detailed inspection report, executive summary chart, summary of recommendations, and an interactive debriefing to review material.

By taking advantage of Haws’ ANSI Emergency Shower and Eye/Face Wash Survey Program, you will be able to ensure your facility not only meets the most recent ANSI Z358.1 Standards, but also provide proper functionality and appropriate first aid capabilities in the event of an emergency.

Learn more about the Haws Survey Program.

ANSI Site Survey Helps Leading Chemical Producer Meet Safety StandardsBACKGROUND

Assuring chemical products are disposed of safely, with human health and environment in mind, should be high priority for any chemical manufacturer. As one of the leading producers of olefin and polyolefin, a U.S. plant makes conducting business in a safe, injury free, and environmentally responsible manner more than just a way of doing business, but also an ethical principal actively demonstrated on a daily basis. Although this level of safety is thoroughly practiced throughout the company, hazards are still a reality, therefore a facility must be equipped with suitable emergency response equipment at all times.

OBJECTIVE

Within their Research Center resided over 30 outdated, non-compliant emergency showers and eyewashes. The units did not meet the ANSI Z358.1 standard due to their installation time and age, which was prior to the issuance of the original Z358.1 standard in 1981. And, as there is no grandfather clause within the standard, the onsite EHS Supervisor knew the units needed to be upgraded and brought up to current compliance, otherwise OSHA fines could ensue.

SOLUTION

When the Supervisor was offered a complimentary onsite ANSI-compliance survey of their emergency showers and eyewashes courtesy of a local Haws® representative, the Supervisor was introduced to the AXION® technology and took an immediate liking to its unique, comfortable water streams. In addition, the safety professional was drawn to the Haws products because they are the only product on the market with flushing capabilities consistent with EMT and emergency room procedures. After the survey debriefing, the Supervisor and Haws Representative created a detailed action item list for the multiple non-compliant units to be upgraded. Once the needed equipment and parts were received, all of the units were effortlessly converted to AXION for ANSI Z358.1 compliance.

RESULTS

With very little free time, the EHS Supervisor found the Haws ESEW Survey Program and process helpful and made things much easier to manage. The Research Center has also signed up to take advantage of Haws’ Annual Inspection offering, as a comprehensive annual test is required by ANSI. “Reviewing the process afterwards, we were not sold anything we didn’t need. It was a great experience working with such an honest company as Haws,” said the Supervisor.

ABOUT THE PROGRAM

As the industry leader, Haws can help bring awareness to the hidden dangers of inadequate emergency response by providing your facility the opportunity to receive a complimentary ANSI compliance emergency shower and eye/face wash survey. The onsite review includes a detailed inspection report, executive summary chart, summary of recommendations, and an interactive debriefing to review material.

By taking advantage of Haws’ ANSI Emergency Shower and Eye/Face Wash Survey Program, you will be able to ensure your facility not only meets the most recent ANSI Z358.1 Standards, but also provide proper functionality and appropriate first aid capabilities in the event of an emergency.

To learn more or sign up for the program, please visit www.hawsco.com/survey.

Are Your Emergency Showers and Eyewashes Properly Installed?The ANSI/ISEA Z358.1 Standard for emergency showers and eyewashes requires that all equipment needs to be installed in a location that is well lit. The standard also states all emergency showers and eyewashes are to “be located in an area identified with a highly visible sign positioned so the sign shall be visible within the area served by the emergency shower.”

These are considered low impact issues that don’t necessarily exclude the equipment from being able to provide proper first aid in the event of an emergency, but they are still liable to receive fines from OSHA for non-compliance with the standard.

Does your equipment meet this one of many requirements of the standard? If you’re unsure and would like to find out, Haws has various useful tools to assist you:

1. Upcoming free webinar: Your Simplified Guide to ANSI Z358.1-2014. Register now>>

2. Check out our ANSI Resources page on our website.

3. Contact us and let us get you to the appropriate person to conduct a site inspection.