With the various uses of formaldehyde, eye and skin contact is a potential occurrence, therefore a safety shower or eyewash should be provided. Formaldehyde is just one of many chemical substances that could come in contact with the eyes or body, requiring emergency response equipment to be readily available.

by Clare Condon

[via EHS Daily Advisor]

Formaldehyde is back in the news now that the U.S. Environmental Protection Agency (EPA) has issued a new rule to control formaldehyde emissions from certain products. However, if your facility uses formaldehyde, as an environment, health, and safety (EHS) manager you have been required for a long time to safeguard your workers from formaldehyde exposure under Occupational Safety and Health Administration (OSHA) workplace safety requirements. Today we will offer some tips for working safely with formaldehyde.

Formaldehyde is a fairly common chemical substance. It’s used to make clothing, textiles, furniture, and building products. It’s also a by-product of some forms of combustion. Formaldehyde is well known as a preservative in medical laboratories, as an embalming fluid, and as a sterilizer. In addition, OSHA has found that some hair smoothing products may contain formaldehyde, may release formaldehyde at levels above OSHA’s permissible limits during use, and may be mislabeled, all of which can pose health risks to salon workers.

For airborne formaldehyde, the permissible exposure limit (PEL) is just 0.75 parts per million (ppm) of air over an 8-hour time-weighted average. Most protective measures have to be instituted at the OSHA action level of 0.5 ppm for an 8-hour time-weighted average and/or the short-term exposure limit (STEL) of 2 ppm for 15 minutes.

While formaldehyde’s most serious hazards relate to health, there are others. Exposing it to heat or flame can cause a fire or explosion, depending on how much formaldehyde a solution contains. Formaldehyde is also reactive with a number of substances. You risk a violent reaction if you mix it with strong oxidizers. In addition, you’ll get explosive compounds if you mix it with nitrogen oxide, nitromethane, perchloric acid and aniline, or peroxyformic acid.

Nine Tips for Working with Formaldehyde

Tip 1: Identify exposure risks. There are a number of ways to identify potential formaldehyde exposure risks. First, formaldehyde has a pungent odor that’s easy to recognize. It also often causes eye irritation. That’s one identifier, but you can’t depend on it. People often get used to the smell and eye irritation and stop noticing it.

Checking the label and safety data sheet (SDS) before using any substance will also alert you to formaldehyde. At the very least, it will be listed on the label. If the substance can release formaldehyde at levels above 0.5 ppm, the label must list all hazards, including respiratory sensitization and the words “May Cause Cancer.”

Tip 2: Wear the PPE. Always wear the personal protective equipment (PPE) that’s assigned, and inspect it carefully before use. If it gets contaminated, don’t take it home. It has to be cleaned or laundered before reuse. Remove it in the change room, and put it in a container labeled for formaldehyde.

Tip 3: Prevent releases. To prevent formaldehyde releases, OSHA also requires regular container inspections to look for leaks and spills. Potential spill areas have to be designed for containment and decontamination. Only trained, properly equipped people repair leaks and clean up spills. Dispose of contaminated waste and debris in sealed containers with formaldehyde hazard warning labels.

Tip 4: Prevent fires. Formaldehyde is extremely flammable. Do not use near open flames or in places where there is the potential for sparks. Do not smoke in areas where formaldehyde is used. In case of a fire, shut off supply. If possible and there is no risk to surroundings, let the fire burn itself out. In other cases extinguish with powder or carbon dioxide.

Tip 4: Prevent explosions. Formaldehyde mixes well with air and explosive mixtures are formed easily. You can prevent explosions by using formaldehyde only in a closed system with proper ventilation. Make sure the electrical equipment and lighting in areas where formaldehyde is used is explosionproof. In case of a fire in a cylinder holding formaldehyde, you can help avoid an explosion by keeping the cylinder cool by spraying with water.

Tip 5: Respond in case of inhalation. Get a formaldehyde inhalation victim to fresh air immediately. Rescuers must wear self-containing breathing apparatus (SCBA) to enter an area with very high formaldehyde concentrations. Keep the person warm and at rest and give artificial respiration if breathing has stopped. Get immediate medical attention. Serious coughing or upper respiratory irritation may require hospitalization for observation.

Tip 6: Respond in case of ingestion. Give a conscious victim milk or water to dilute the formaldehyde. Keep the person warm and at rest; for vomiting, keep the head below the hips. Get immediate medical attention.

Tip 7: Respond in case of skin contact. Remove contaminated clothing. Shower immediately after skin contact. Rinse with soap and lots of water for at least 15 minutes. Cover a skin or eye burn with a sterile bandage and get immediate medical attention. Also get checked if you have any notable eye or respiratory irritation.

[highlight]Tip 8: Respond in case of eye contact. Use eyewash immediately after eye contact. Use large amounts of water for at least 15 minutes. Remove contact lenses if easily possible. Get immediate medical attention.[/highlight]

Tip 9: Provide training. OSHA’s formaldehyde standard requires employers to train all employees who are assigned to work areas with the potential for formaldehyde exposure at or above 0.1 ppm. Employees must be trained at the time of initial assignment and at least once a year thereafter. They must also receive training whenever a new exposure to formaldehyde is introduced into the work area.

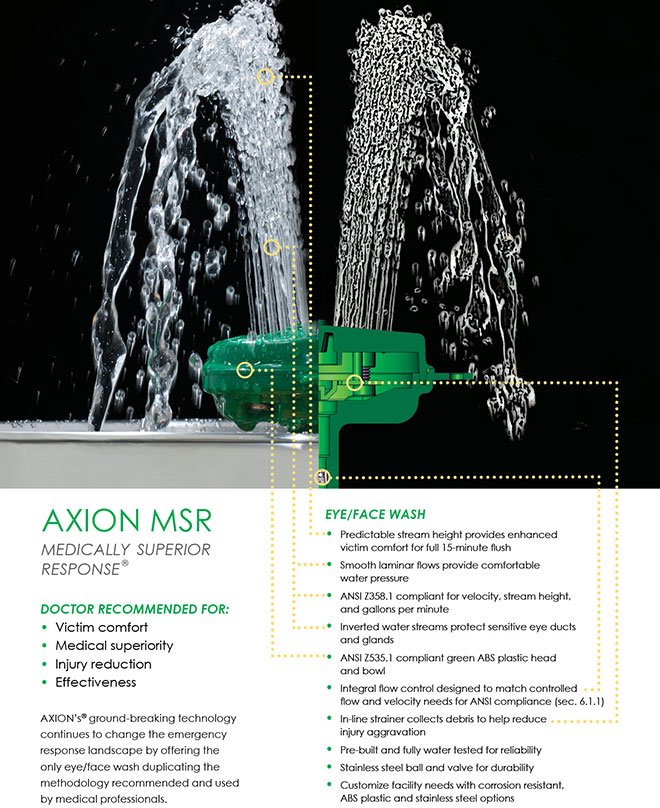

Why AXION MSR™ is truly a Doctor’s First ChoiceLearn from Ophthalmologist Dr. Robert S. Wolff, MD why the AXION MSR is the ideal eye/face wash for following standard healthcare protocols,

“I worked with the Haws Corporation® to launch AXION MSR emergency eye/face wash products. Haws recognized that traditional configurations for irrigating injured eyes were at odds with the protocols used by healthcare professionals. That is, traditional eyewash designs can actually sweep contaminants toward the inner corners of the eyes. AXION MSR eye/face wash features the only inverted flow streams specifically designed to operate in concert with standard healthcare protocols.“

The ideal approach in chemical or particulate eye injuries is to sweep contaminants away from the interior of the eye. This method is practiced in doctor’s office and hospitals yet was not followed in the safety industry. Haws® recognized this need to protect the human eye and other internal organs and reversed the water flow to flush from the inside out for maximum effectiveness, injury reduction and enhanced victim comfort.

The ideal approach in chemical or particulate eye injuries is to sweep contaminants away from the interior of the eye. This method is practiced in doctor’s office and hospitals yet was not followed in the safety industry. Haws® recognized this need to protect the human eye and other internal organs and reversed the water flow to flush from the inside out for maximum effectiveness, injury reduction and enhanced victim comfort.

AXION products are available on the most popular configurations: combination showers as well as wall-mounted and pedestal eye/face washes. Get your medically superior response product from AXION MSR™