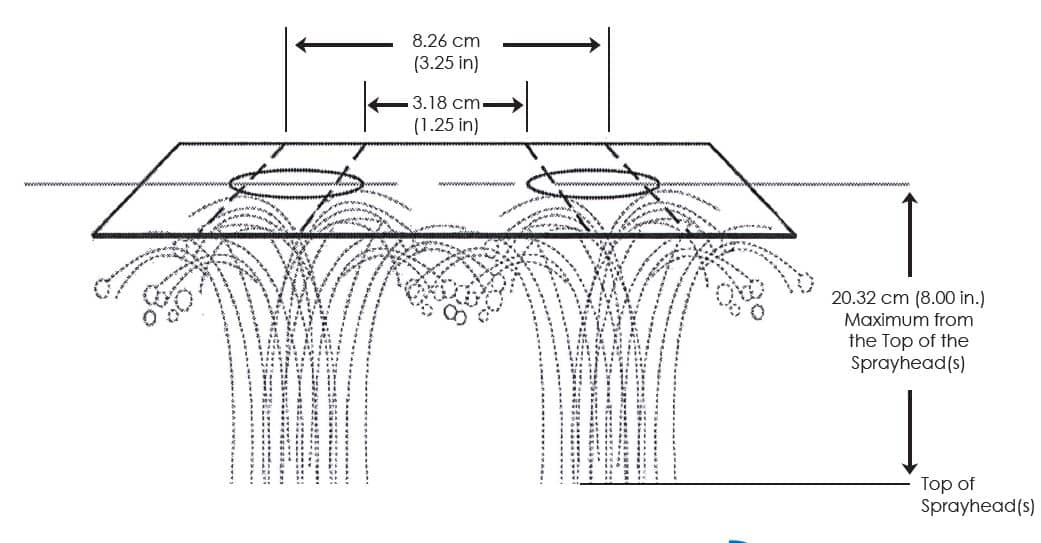

The ANSI Z358.1 Standard states that to determine a suitable eyewash pattern, the eyewash testing gauge should be a minimum of 4 inches in length with two sets of parallel lines equidistant from the center. The interior of the lines should be 3.25 inches apart. (Section 5.1.8)

1. Activate the eye/face wash. Note: If the eye/face wash is a part of a combination unit, ensure all other outlets are activated to confirm proper flow and simultaneous use. (Section 7.1)

2. Place the testing gauge in the streams of the eyewash. (Section 5.1.8)

3. The flushing fluid should cover the areas between the interior and exterior lines of the gauge at some point less than 8 inches above the eyewash nozzle. (Section 5.1.8)