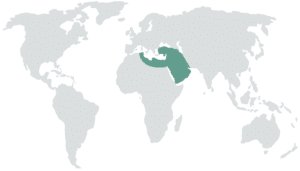

Haws – Switzerland announced its expansion into new markets in the Middle East, increasing its investment and presence to come closer to partners in key markets. This new extension will provide immediate access for customers in the region to help Haws better serve their needs and to develop stronger partnerships with local entities.

Haws – Switzerland announced its expansion into new markets in the Middle East, increasing its investment and presence to come closer to partners in key markets. This new extension will provide immediate access for customers in the region to help Haws better serve their needs and to develop stronger partnerships with local entities.

Recently, Haws welcomed two regional sales team members, Sampeep Verma and Michael Alex, as Business Development Managers – Middle East. Mr. Verma and Mr. Alex split territory coverage with specific regions assigned.

“Over the last 30 years, we have made tremendous progress in establishing Haws as a significant player in the EMEA safety equipment marketplace and expanding our reach to local markets. As one of the fastest growing markets globally, Middle East is an important and strategic region to continue our growth plans,” said Urs Weder, Manager Director of Haws – AG.

The Haws team will be showcasing new products and services at the A+A International Trade Fair and Congress in Dusseldorf in October in Hall 7A at Booth F13.

For more information, visit www.Haws.ch or [email protected].

OSHA and ANSI Requirements for Eyewash and Safety Showers

[via LabManager.com]

ANSI standard Z358.1 is detailed in terms of defining what is appropriate for safety showers and eyewash stations.

As lab managers and employees, we know that many inorganic chemicals (such as the mineral acids and alkalis) are corrosive to the skin and eyes. Likewise we are aware that many organic chemicals (such as acid halides, phenols, and so on) are corrosive and often toxic. Yet we Safety Guys are continually shocked by laissez-faire attitudes toward the use and maintenance of basic safety equipment by lab personnel, and the resultant unnecessary injuries.

One extreme example we constantly recall is the tragic UCLA accident just a few years ago, which resulted in a fatality from chemical burns.1 And we recently noticed a post on the American Industrial Hygiene Association pages for Lab Safety Chemical Exposure Incidents, where improper use of an eyewash resulted in a trip to the emergency room.2

The worker was using a fluorescent stain in the cytogenetics lab and felt something splash into his eyes. He was not wearing safety goggles or glasses. (D’oh!) Long story shortened, he flushed his eyes at the nearest eyewash, but they remained irritated and began to swell shut, necessitating a visit to the emergency room. Back at work a few days later, he noticed a coworker using the same eyewash to clean glassware and stainless steel trays, which were left resting in the sink in a cleaning solution. (What?!)

What does OSHA say?

In 29 CFR 1910.151 Medical Services and First Aid, it states that “where the eyes or body of any person may be exposed to injurious corrosive materials, suitable facilities for quick drenching or flushing of the eyes and body shall be provided within the work area for immediate emergency use.”3 OSHA doesn’t provide more specifics regarding what constitutes “suitable” or how “immediate” is defined. So how do we know if we are meeting the intent of the law?

Fortunately, we have the American National Standards Institute (ANSI), and their consensus standard Z358.1, last updated in 2014. This ANSI standard is very detailed in terms of defining what is appropriate for safety showers and eyewash stations. In fact, OSHA uses this reference as a guide when inspecting facilities. So let’s review what is “recommended” for acceptable safety equipment.

Safety shower specs

Begin by checking your facilities for the proper hardware, as recommended by Z358.1. Rest assured that OSHA will, should one or more agents show up for an inspection. For safety showers, the shower head must be capable of flowing 20 gallons per minute (gpm) at 30 psi and producing a 20-inch diameter spray pattern at 60 inches above the surface where the user stands. The center of the sprayhead pattern should be at least 16 inches from any wall, door, or obstruction. It is recommended that the shower head be mounted between 82 and 96 inches off the floor, with the valve no higher than 69 inches.

Eyewash specs

Eyewash stations target just the eyes and therefore have a lower flow requirement. ANSI Z358.1 recommends a flow of 0.4 gpm also at 30 psi. The nozzles should be at least six inches from any obstruction and mounted between 33 and 45 inches above the floor. An eyewash gauge should be used to verify and test the flow pattern.

Requirements for both

Both safety showers and eyewash stations must be able to provide the recommended flow for at least 15 minutes. This usually translates into having the equipment plumbed in with hard connections to the water supply. For example, a quick calculation for the safety shower at 20 gpm yields 300 gallons needed. Self-contained or personal wash devices are allowed, but they are considered supplemental units that can provide immediate flushing while transiting to the permanent fixture.

If the local climate presents potential for freezing conditions, the equipment must be designed to avoid freezing or protected against that situation. Activation valves must open within one second and remain open until intentionally closed or turned off. It goes without saying that these safety devices should be constructed of corrosion-resistant materials.

The 2014 update to Z358.1 added two important criteria. The first is that the requirement for tepid water is now defined as having a temperature of between 60 and 100 degrees Fahrenheit (15 to 37 degrees Celsius). The second change addresses simultaneous operation for combination units. This means that if you have a drench shower combined with an eyewash station, both devices must provide adequate flows and be fully operable at the same time.

Finally and most importantly, consider the location of equipment. We know you have the 10-second rule etched into your brain, as that is the most critical element when it comes to safety showers and eyewashes. This means that travel to the unit should be under 10 seconds for all hazardous areas that need this equipment. This equals about 55 feet. In addition, the drench shower or eyewash must be on the same level as the hazard and have a clear path for travel. We recommend painting or marking the floor area underneath the shower to help keep it clear. Z358.1 also recommends equipment be installed in a brightly lit area and marked with a highly visible safety sign.

Maintenance and training

The last thing you want is to rush to the eyewash or shower, only to be drenched with nasty, sediment-laden water. ANSI recommends flushing all equipment weekly to verify proper flow, and clearing the plumbing of any deposits. If your facility does not have floor drains installed, remember to bring a large, plastic trash can to catch the water. The weekly flushing can also provide a great training opportunity to refresh the operation and travel paths for your employees.

If you want to find out about the ANSI/ISEA Z358.1 significant requirements, attend our free 1-hour webinar on September 21st, 2017.

Register now and become subject matter experts of your emergency eyewash and shower equipment including weekly and annual testing. Request a certificate of attendance after the webinar.

This free webinar will cover:

• ANSI/ISEA Z358.1 significant requirements

• Important 2014 revision highlights

• Compliance best practices

• Live Q&A

WHAT: All You Need to Know About ANSI Z358.1 Webinar

WHEN: September 21, 2017 from 10am-11am PT / 1pm-2pm ET

PRESENTER: Justin Dunn, Product Specialist/Trainer and Samantha Hoch, Marketing Strategist

HOW: Register for free

Attendees will receive these complimentary materials after the webinar:

• OSHA white paper

• Weekly and Annual ANSI Checklist

• Access to On-Demand Webinar

References

1. “tert-Butyllithium Claims Fellow Chemist at UCLA,” Chemistry Blog, January 19, 2009, http://www.chemistry-blog.com/2009/01/20/tert-butyllithium-claims-fellow-chemist-at-ucla/.

2. “Lab Safety Chemical Exposures Incidents,” American Industrial Hygiene Association, https://www.aiha.org/get-involved/VolunteerGroups/LabHSCommittee/Incident%20Pages/Lab-Safety-Chemical-Exposures-Incidents.aspx.

3. “Medical Services and First Aid,” US Department of Labor, Occupational Health and Safety Administration, https://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=STANDARDS&p_id=9806.

Haws Receives Safety 2017 Attendee Choice Award

ISHN’s annual hands-on safety and health products and services awards – a complement to the Reader’s Choice Awards — are based on voting by attendees at the American Safety of Safety Engineers (ASSE) annual professional development conference.

Haws is proud to announce that our Tempered, Gravity-Fed, Portable Eyewash model 7501T is a winner in the category of Emergency Eyewashes at this year ASSE Safety 2017 conference Attendees Choice Award.

Model 7501T is a compact portable tempered eyewash and is ideal for remote locations. The 9-gallon (34 L), gravity-fed, eyewash uses a heated, insulated blanket to provide ANSI compliant tempered potable water in operating temperatures between -30° F (-34° C) and 100° F (38° C) for locations without access to a continuous potable water source. The self-contained heating blanket electrical system uses NEMA 3R rated components. 120V electrical requirement with supplied 8′ power cord.

- Featuring an FDA approved high-density green polyethylene tank easily activated by pulling the yellow activation arm down to the open position

- A wide-fill opening with threaded cap permits easy inspection, cleaning, and filling

- Relocation is simple due to the easily mounted bracket (included) and light design of this 9-gallon (34 L) portable

To see a complete line of Portable Eyewash solutions visit our website.

A Legacy of Innovation

By Stephanie Kilroy

One hundred and ten years ago, Luther Haws created a drinking solution that would become the first product for Haws Sanitary Drinking Faucet Company. Luther saw children drinking from a common cup on a playground at a public school; as a result, he invented a bubblerhead drinking faucet. This innovation sparked what would eventually be an enterprise business employing over two hundred employees globally.

The product innovation initiated by Luther Haws continued across generations. In the 1940’s, maintenance men from an oil refinery in Richmond, CA would come by the Haws plant in Berkeley to shop for parts: round ball type bubblers, flow regulator and fittings. After inquiring about the need for these spare parts instead of completed models, Haws was informed that these parts were being used to build equipment to flush eyes. Employees at Haws sought to understand the needs of the customer and began making these emergency eyewashes and drench showers for them. This was the unofficial launch of Haws emergency equipment products; the earliest drawings date back to 1949.

Haws employees have great pride in our innovative spirit which continues to thrive in 2017. One of Haws’ recent accomplishments has been the development of a professionalized R&D department. Under the leadership of Michael Joyer, new ideas are being generated regularly with many of these innovative ideas already introduced to the market. For example, the 7501T Tempered, Gravity-Fed, Portable Eyewash was one of the first products borne out of the R&D lab.

Haws employees have great pride in our innovative spirit which continues to thrive in 2017. One of Haws’ recent accomplishments has been the development of a professionalized R&D department. Under the leadership of Michael Joyer, new ideas are being generated regularly with many of these innovative ideas already introduced to the market. For example, the 7501T Tempered, Gravity-Fed, Portable Eyewash was one of the first products borne out of the R&D lab.

Haws is also called to innovate, not simply with new products, but in the way we do business. We are a stable, multigenerational family company, we are learning to change and improve processes. Haws employees are looking for internal efficiencies and ways in which we can best meet the needs of our customers. Recently, the Production team has developed a cross-training initiative aimed at flexing team work assignments to serve business demands.

These types of cross-functional, support teams are increasing and delivering impactful deliverables. In Q1, Marketing and Customer Service launched a Live Chat program on the Haws website to provide immediate access to customers. The Haws China website launch is another joint effort initiative intended to widen our global marketplace coverage. Launched in Q2 2017, this was a true collaboration between the Haws China and Corporate Marketing teams. And these are just a few of the examples of all the successful small and large activities that are helping drive change to redefine how we innovate, how we grow and how we foster a culture that is rewarding for all.

One hundred and ten years later, Haws continues our commitment to inventing, designing and manufacturing hydration products as well as standardized and customized emergency response products. With more than 8,000 distribution locations and 200 employees worldwide, we continually focus on quality, service, reliability and complete solution support. Headquartered in Sparks, Nevada, USA, Haws is globally represented with locations in Switzerland, Singapore, China, India, and Brazil. For more information on Haws, visit www.Hawsco.com.

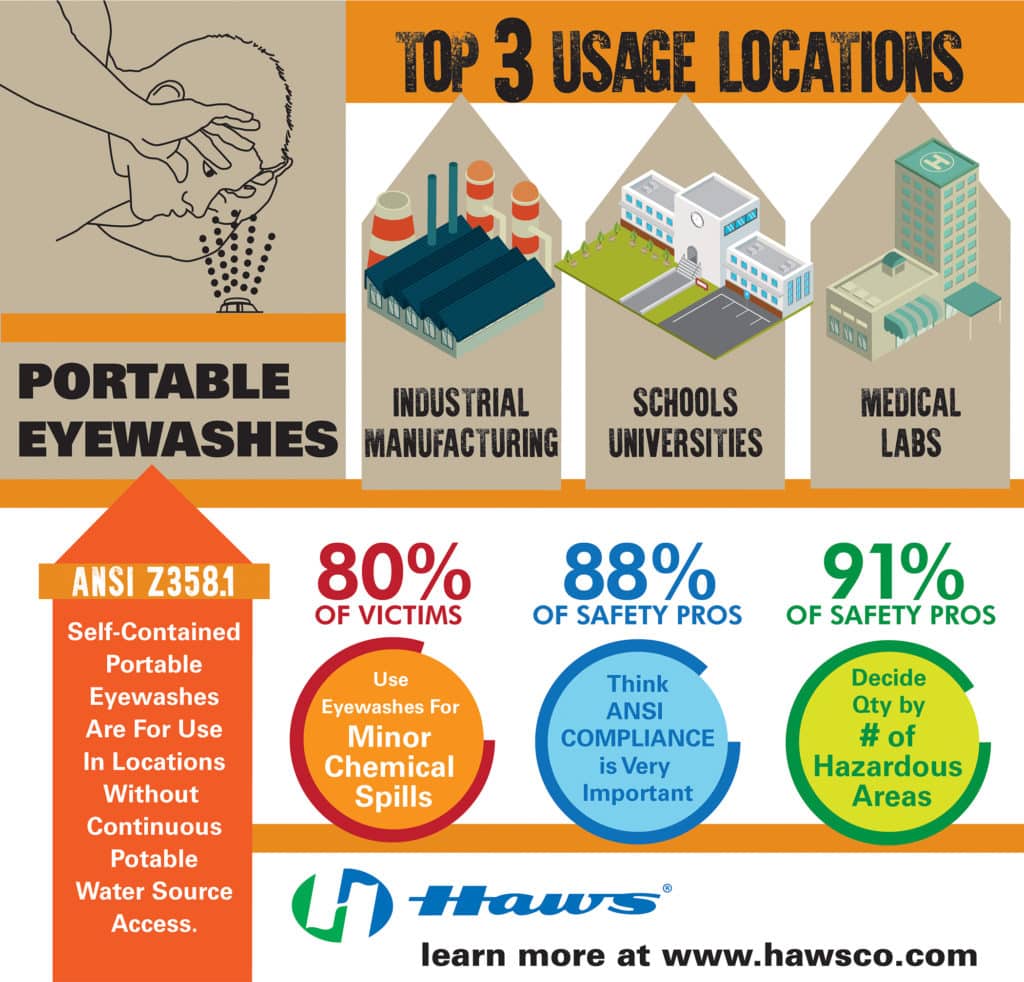

Infographic: Top 3 Usage Locations of Portable EyewashesWhat are portable eyewash stations?

A portable emergency eyewash is a self-contained ANSI Z358.1 compliant emergency response product that is needed for locations without access to water and can be moved at a moments notice to meet the rapidly evolving needs of a chemical, manufacturing, or construction environment.

When is a portable eyewash station needed?

A portable emergency eyewash can be used anywhere an emergency eyewash system is needed but does not have access to a continuous source of potable water. The advantage over plumbed units is the mobility feature. This allows safety professionals to relocate the equipment as needed to stay compliant with ANSI and OSHA emergency equipment distance requirements.

ANSI Z358.1 FAQ: What is the Weekly Test vs. the Annual Test?Are you unsure of when you should test the emergency showers and eyewashes in your facility? Do you know the difference between the weekly and annual testing requirements? In certain cases, a full 15-minute drench period is not required, however it is important to know what is required on a weekly basis versus annually.

ACTIVATE WEEKLY

Per the ANSI Z358.1 standard, you are required to activate the emergency equipment weekly to verify operation and to ensure there is a flushing fluid supply and clear the supply line of any sediment build-up that could prevent the flushing fluid from being delivered due to stagnant water.

How long do you activate for? ANSI states the duration of the weekly activation depends on the amount of water contained in the unit itself and all sections of pipework that are not a part of a constant circulation system, also known as the “dead leg” portions. The goal of the weekly activation is to flush out the stagnant water in the dead leg completely.

TEST ANNUALLY

All emergency eyewashes, eye/face washes, showers and combination units are required to be fully inspected annually to ensure conformance with the installation section of the Z358.1 standard for that type of equipment. The following some of the requirements that need to be met for the annual test:

- The equipment must be assembled and installed in accordance with the manufacturer’s instructions, including flushing fluid delivery requirement.

- Equipment must be accessible within 10 seconds, located on the same level as the potential hazard, and must be free of obstructions that may inhibit immediate use.

- Must be identified with well-lit, highly visible signage.

- Equipment must be connected to a supply of flushing fluid that can produce the required flush time of a full 15 minutes.

- Where the possibility of freezing conditions exists, equipment must be protected from freezing or freeze-protected equipment must be installed.

- Must deliver tepid flushing fluid for the full 15-minute drench period.

- Equipment must go from “off” to “one” in one second or less.

- Must provide a controlled flow of flushing fluid at a velocity low enough to be non-injurious to the user.

How long do you activate for? As stated above, you need to ensure the equipment is is delivering tepid flushing fluid for a full 15 minutes.

For full detailed information on the ANSI Z358.1 requirements for Emergency Eyewashes and Showers, watch the FREE on-demand webinar HERE.

For more ANSI resources such as a testing checklist, click here.

Preparation: The Best Guard to an EmergencyDo you know the protocol to flushing hazardous chemicals off of your body in an emergency? It’s always a good rule of thumb to be knowledgeable on how to properly execute safety shower and eyewash performance in an emergency situation. Take the time to get to know the mechanics of the emergency equipment in your facility before an accident takes place. Casey Hayes, director of Haws Integrated™, recommends the following:

- Get a proper training session on emergency equipment. Be aware of the location of the unit and how long it takes to arrive at the unit from your work space.

- Confirm that it should not take more than 10 seconds to arrive to the emergency equipment.

- Upon arrival to the shower, pull lever and remain in shower for a full 15 minutes. This is to ensure the prevention of chemical absorption while it also helps to cool burns and prevent hypothermia.

- When using an eyewash or eye/face wash, hold eyes open during the entire 15 minute flushing period.

- In some cases, it may be appropriate to have a partner with you during the state of emergency. If you work alone, you may not have the opportunity to have someone assist you. We recommend that if you are in a state of shock, have a co-worker assist you to the emergency shower and or eyewash station. If you are saturated in chemicals, it is best not to expose anyone else and to proceed to the emergency station alone.

- Always go to the emergency room following the use of the emergency shower and/or eyewash.

Furthermore, it’s essential to have functional emergency showers and eyewashes throughout your facility. Refer to our previous blog post ANSI Z358.1 FAQ: What is the Weekly vs. Annual Test for a break down on when it is appropriate to perform each test. We also offer a free webinar on the requirements for emergency eyewashes and showers. Click here to watch.

Social Frenzy: Emergency Showers & Eyewashes in Action

OSHA regulations vary for eyewash flushing & shower drenching

Written by: Wesley J. Maertz

Written by: Wesley J. Maertz

The question often comes up as to where OSHA calls out eyewash requirements. Emergency shower and eyewash station equipment needs are referenced in two different types of OSHA regulations. The first is applicable to all general industry or construction facilities that require the installation of emergency shower or eyewash station equipment. The second type is specific to certain industries.

Both regulation types specify where and when emergency eyewash and shower equipment must be available. Neither, however, specifies minimum selection, installation, operation or maintenance requirements. For the answers to these questions, organizations must turn to the American National Standards Institute (ANSI)/ International Safety Equipment Association (ISEA) American National Standard for Emergency Eyewash and Shower Equipment standard, (ANSI/ISEA Z358.1-2014).

General applicable regulations

When working with corrosives, drenching facilities must be readily available according to 29 Code of Federal Regulations (CFR) 1910.151(c) for general industry and 29 CFR 1926.50(g) for construction industry. Both state, “Where the eyes or body of any person may be exposed to injurious corrosive materials, suitable facilities for quick drenching or flushing of the eyes and body shall be provided within the work area for immediate emergency use.” These drenching facilities could include an eyewash, eye/face wash, shower or combination eye/face wash shower depending on the amount of possible exposure. Because OSHA does not clarify the minimum requirements for “suitable facilities,” employers often look to the ANSI/ISEA Z358.1 Standard for Emergency Eyewashes and Shower Equipment for guidance.

Specific industry applicable regulations

There are also industry specific regulations that address emergency drenching requirements. You must be familiar with these specific requirements if they apply to your workplace:

♦ Open Surface Tanks 29 CFR 1910.124(g)(2) and(3):

“An emergency shower and eye-wash station close to the dipping or coating operation. In place of this equipment, you may use a water hose that is at least 4 feet (1.22 m) long and at least 3/4 of an inch (18 mm) thick with a quick-opening valve and carrying a pressure of 25 pounds per square inch (1.62 k/cm2) or less; and at least one basin with a hot-water faucet for every 10 employees who work with such liquids.

♦ Anhydrous Ammonia 29 CFR 1910.111(b)(10)(iii)

“Stationary storage installations shall have an easily accessible shower or a 50-gallon drum of water.”

♦ Powered Industrial Trucks 29 CFR 1910.178(g)(2)

“Facilities shall be provided for flushing and neutralizing spilled electrolyte, for fire protection, for protecting charging apparatus from damage by trucks, and for adequate ventilation for dispersal of fumes from gassing batteries.”

♦ Pulp, Paper, and Paperboard Mills 29 CFR 1910.261(g)(5)

“…A deluge shower and eye fountain shall be provided to flush the skin and eyes to counteract lime or acid burns.”

♦ Telecommunications 29 CFR 1910.268(b)(2)(i)

“…Facilities for quick drenching or flushing of the eyes and body shall be provided unless the storage batteries are of the enclosed type and equipped with explosion proof vents, in which case sealed water rinse or neutralizing packs may be substituted for the quick drenching or flushing facilities. Employees assigned to work with storage batteries shall be instructed in emergency procedures such as dealing with accidental acid spills.”

♦ Formaldehyde 29 CFR 1910.1048(i)(3)

“If there is any possibility that an employee’s eyes may be splashed with solutions containing 0.1 percent or greater formaldehyde, the employer shall provide acceptable eyewash facilities within the immediate work area for emergency use.”

Consensus applicable regulation

ANSI/ISEA Z358.1-2014 is a voluntary national consensus standard that OSHA refers employers to as a recognized source for guidance. It helps users select, install, operate and maintain emergency eye wash and shower equipment. The standard is divided into five sections and each section addresses minimum performance and use requirements, as well as installation, testing procedures, maintenance and training requirements. OSHA often uses ANSI/ISEA Z358.1-2014 as a guide during inspections and may elect to issue penalties based on non-compliance.

To ensure that eyewash stations and showers are always ready when needed, it is important that the requirements for test procedures and maintenance set forth in ANSI/ISEA Z358.1-2014 be followed. The requirements for testing and maintaining eye, eye/face washes and showers are based on the manufacturer’s instructions and ANSI protocols. Generally, the manufacturer’s instructions state that the devices should be inspected tested and the results recorded weekly. Individual owners’ manuals should be looked at for the specific manufacturer’s guidelines.

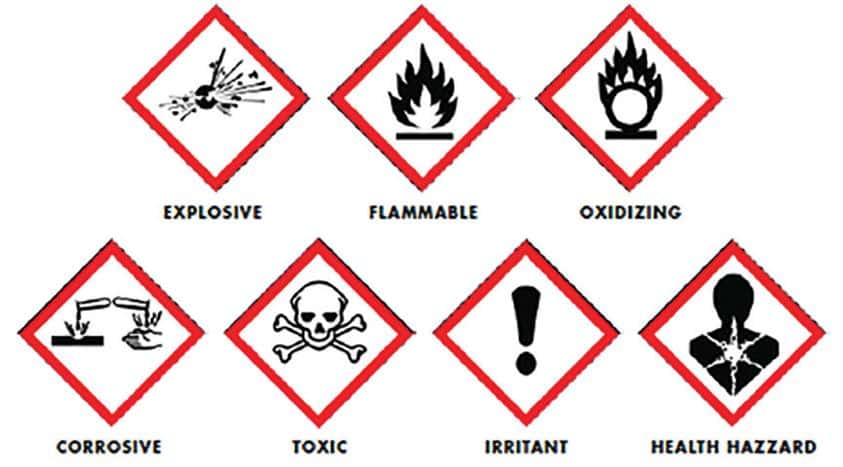

Determination of a corrosive material

Within the general guidelines, occasionally the question comes up as to whether OSHA requires eyewashes for anything other than injurious corrosive chemicals. In a May 5, 2004 letter of interpretation, OSHA states: “As the standard states, an eyewash and/or safety shower would be required where an employee’s eyes or body could be exposed to injurious corrosive materials. If none of the materials used in this work area is an injurious corrosive (as indicated by the Material Safety Data Sheet (MSDS) for each product), then an emergency eyewash or shower would not be required pursuant to 1910.151(c) and 1926(g)”

Corrosive material is present in many workplaces either by themselves or contained in other materials. It is a good idea to refer to several sources to determine if a chemical is considered a corrosive to OSHA’s definition as it applies to eyewashes.

One of the easiest ways to identify if a chemical has corrosive properties is to use OSHA’s Hazard Communication Standard (29 CFR 1910.1200) and the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) as a guide. The universal symbols/pictograms used on labels and containers provide clear indications if a chemical is a corrosive.

Another source to identify if a chemical is corrosive is the Safety Data Sheet (SDS). Section 2 of the SDS will quickly provide the same information found on the shipped container label including the pictogram and precautionary statements. Section 9 of the SDS provides more details about the physical properties of the chemical including pH, which is the measure of how basic or acidic the chemical is on a scale of 0-14. A rating below seven is more acidic and above seven is more basic.

One other source to reference is the NIOSH pocket guide. The pocket guide presents key information such as pH in abbreviated or tabular form for chemicals or substance groupings that are found in the work environment.

View Emergency Equipment Product Solutions here>>

[via ISHN]

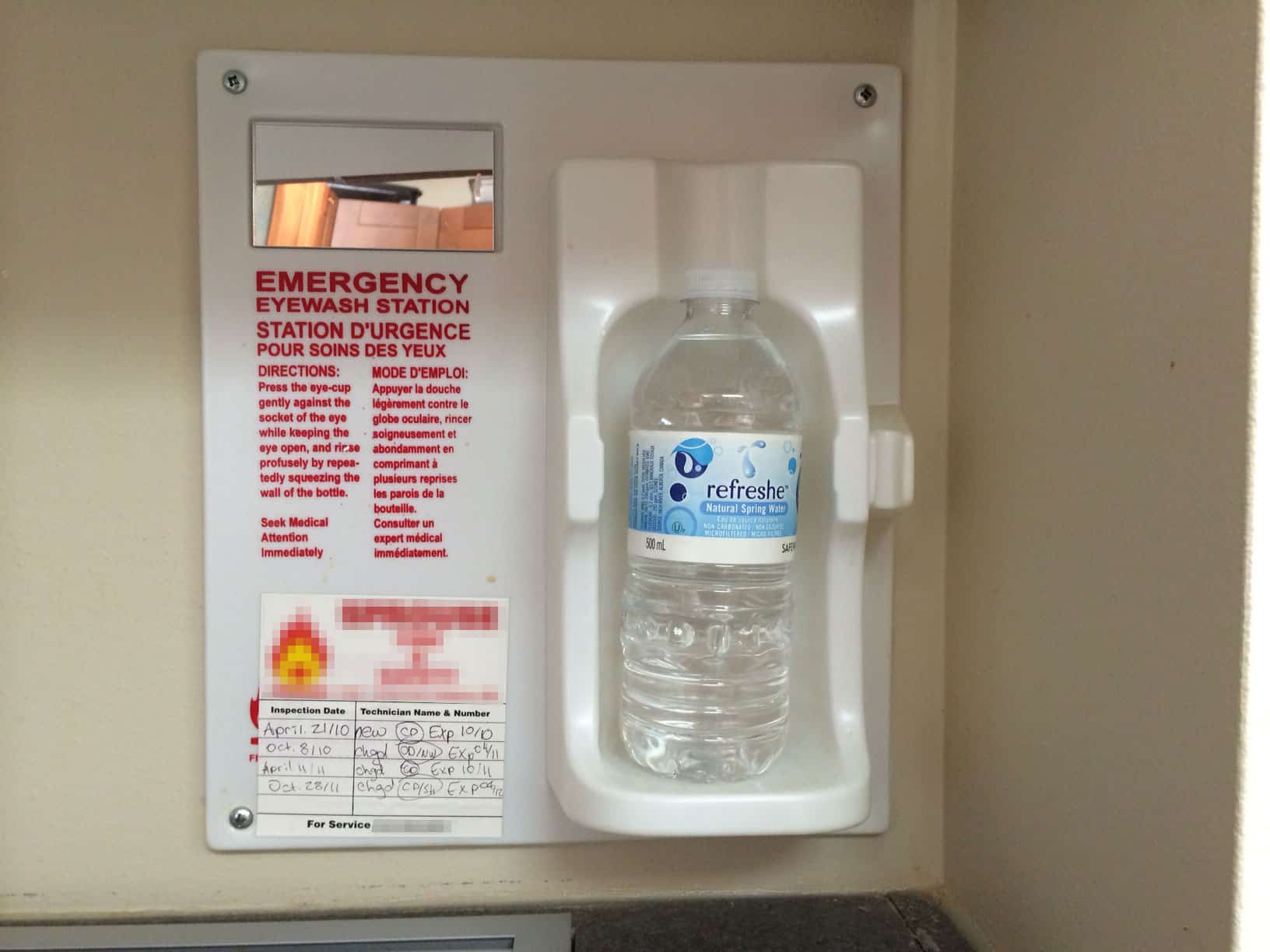

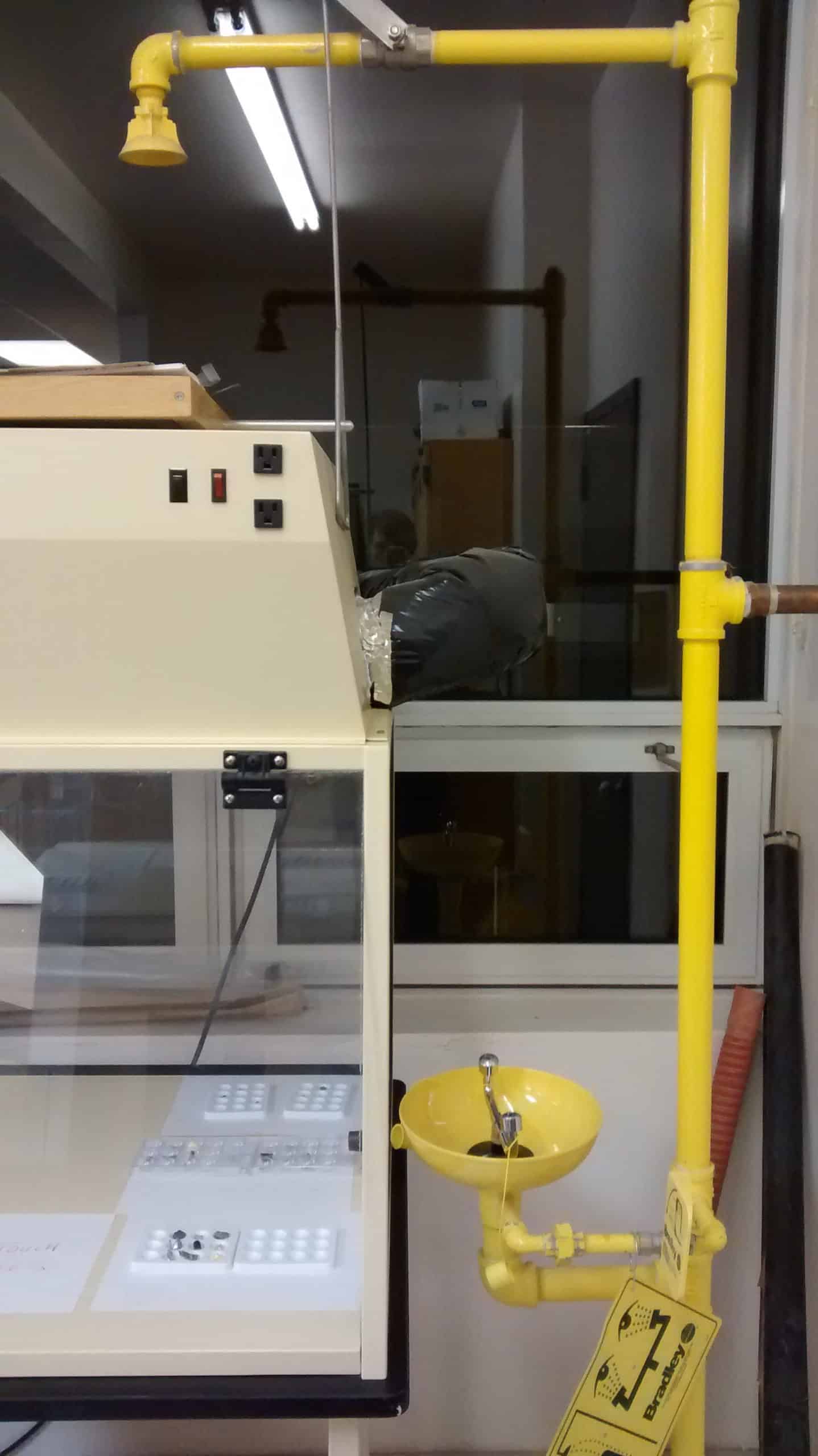

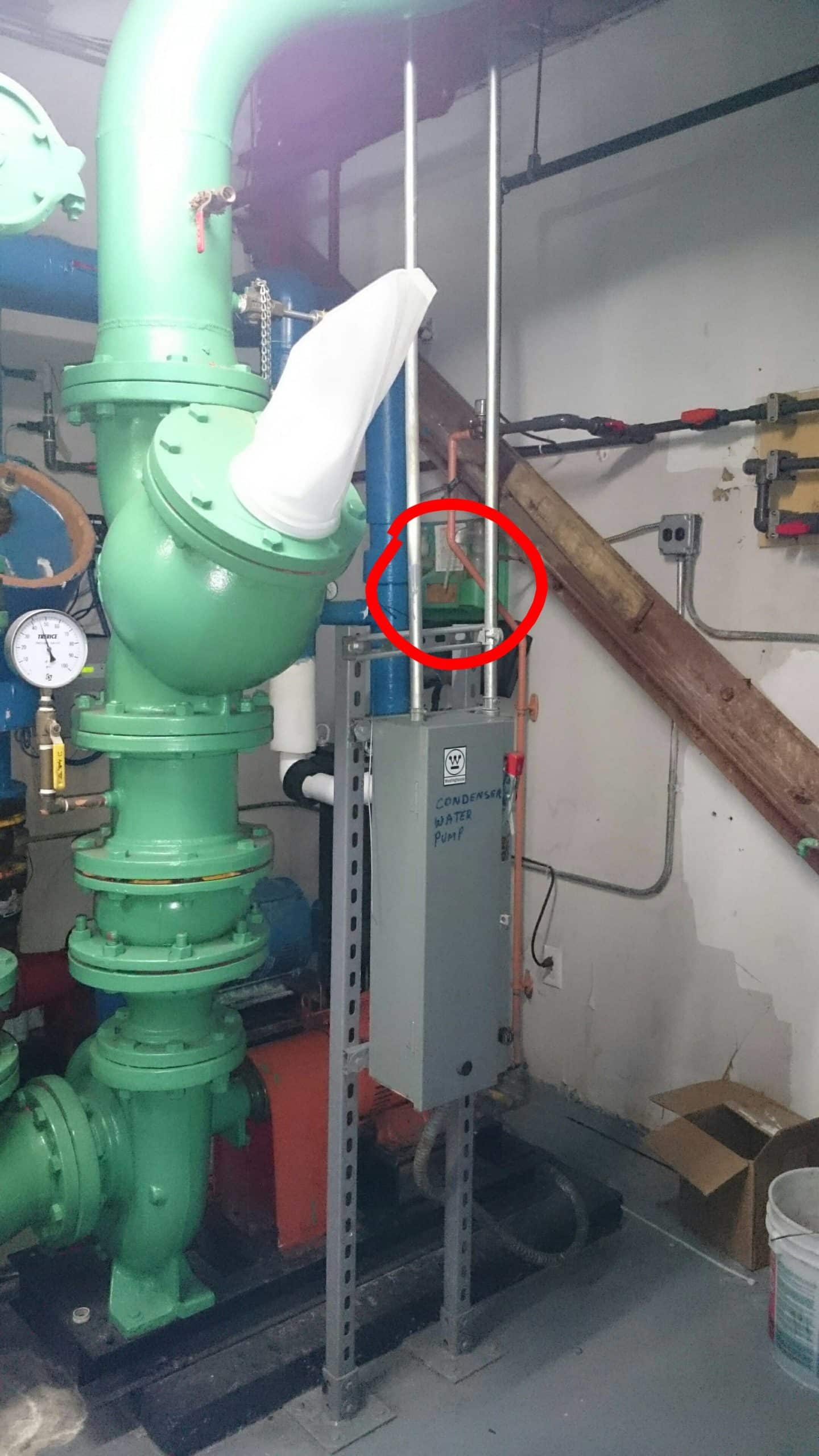

Monday Tip: Emergency Eyewash “No-No’s”It is interesting to see what some facilities consider to be sufficient in regards to providing proper emergency shower and eyewash equipment. Below are just a few of these not-so-compliant “solutions”.

Not only does this risk potential fines from OSHA for not complying with the ANSI Z358.1 Standard, but it also put workers, students, etc. at risk of not having proper functioning equipment to use in the event of an emergency.

Ummm… not quite an equivalent.

I wonder where the user is supposed to stand?

Ever seen a dual-functioning water cooler and eyewash station? Yeah, neither have we.

Can you spot the eyewash station?

Our tip: When installing an eyewash or shower unit, test out an emergency scenario to make sure you are giving a victim the required distance and access. Choose the path of least resistance to guarantee a victim the best treatment possible and to reduce potential injury damage.

For more information on ANSI installation requirements, visit www.hawsco.com/ANSI .

Don’t Miss Haws at the 2015 VPPPA Expo!Haws will be displaying at the Voluntary Protection Programs Participants Association Expo (VPPPA) which attracts some of the most innovative manufacturers of safety, health and environmental products and services. The 31st Annual National VPPPA Safety and Health conference will be held in Dallas, Texas on August 24-27.

Come to booth #1010 to learn more about our various product offerings including our emergency shower and eyewash retrofit kits: the AXION Advantage® upgrade systems.

We look forward to seeing you at booth #1010!

Your Guide to 2014 ANSI Z358.1 Revisions & Best Practices by Casey Hayes

Haws Integrated Director Casey Hayes, is featured in Industrial Safety & Hygiene News (ISHN) April issue with an article titled “Emergency Showers and Eyewash Stations: Your Guide to 2014 ANSI Z358.1 Revisions & Best Practices”. In the article, Hayes provides helpful insights on how to properly use emergency showers and eyewash stations, for maximum victim comfort and ANSI compliance.

Haws Integrated Director Casey Hayes, is featured in Industrial Safety & Hygiene News (ISHN) April issue with an article titled “Emergency Showers and Eyewash Stations: Your Guide to 2014 ANSI Z358.1 Revisions & Best Practices”. In the article, Hayes provides helpful insights on how to properly use emergency showers and eyewash stations, for maximum victim comfort and ANSI compliance.

In an effort to establish minimum performance and use requirements for emergency eyewash and shower equipment, the American National Standards Institute (ANSI) created industry standard ANSI Z358.1 in 1981.”

To view the complete article click here!