Written by: Wesley J. Maertz

Written by: Wesley J. Maertz

The question often comes up as to where OSHA calls out eyewash requirements. Emergency shower and eyewash station equipment needs are referenced in two different types of OSHA regulations. The first is applicable to all general industry or construction facilities that require the installation of emergency shower or eyewash station equipment. The second type is specific to certain industries.

Both regulation types specify where and when emergency eyewash and shower equipment must be available. Neither, however, specifies minimum selection, installation, operation or maintenance requirements. For the answers to these questions, organizations must turn to the American National Standards Institute (ANSI)/ International Safety Equipment Association (ISEA) American National Standard for Emergency Eyewash and Shower Equipment standard, (ANSI/ISEA Z358.1-2014).

General applicable regulations

When working with corrosives, drenching facilities must be readily available according to 29 Code of Federal Regulations (CFR) 1910.151(c) for general industry and 29 CFR 1926.50(g) for construction industry. Both state, “Where the eyes or body of any person may be exposed to injurious corrosive materials, suitable facilities for quick drenching or flushing of the eyes and body shall be provided within the work area for immediate emergency use.” These drenching facilities could include an eyewash, eye/face wash, shower or combination eye/face wash shower depending on the amount of possible exposure. Because OSHA does not clarify the minimum requirements for “suitable facilities,” employers often look to the ANSI/ISEA Z358.1 Standard for Emergency Eyewashes and Shower Equipment for guidance.

Specific industry applicable regulations

There are also industry specific regulations that address emergency drenching requirements. You must be familiar with these specific requirements if they apply to your workplace:

♦ Open Surface Tanks 29 CFR 1910.124(g)(2) and(3):

“An emergency shower and eye-wash station close to the dipping or coating operation. In place of this equipment, you may use a water hose that is at least 4 feet (1.22 m) long and at least 3/4 of an inch (18 mm) thick with a quick-opening valve and carrying a pressure of 25 pounds per square inch (1.62 k/cm2) or less; and at least one basin with a hot-water faucet for every 10 employees who work with such liquids.

♦ Anhydrous Ammonia 29 CFR 1910.111(b)(10)(iii)

“Stationary storage installations shall have an easily accessible shower or a 50-gallon drum of water.”

♦ Powered Industrial Trucks 29 CFR 1910.178(g)(2)

“Facilities shall be provided for flushing and neutralizing spilled electrolyte, for fire protection, for protecting charging apparatus from damage by trucks, and for adequate ventilation for dispersal of fumes from gassing batteries.”

♦ Pulp, Paper, and Paperboard Mills 29 CFR 1910.261(g)(5)

“…A deluge shower and eye fountain shall be provided to flush the skin and eyes to counteract lime or acid burns.”

♦ Telecommunications 29 CFR 1910.268(b)(2)(i)

“…Facilities for quick drenching or flushing of the eyes and body shall be provided unless the storage batteries are of the enclosed type and equipped with explosion proof vents, in which case sealed water rinse or neutralizing packs may be substituted for the quick drenching or flushing facilities. Employees assigned to work with storage batteries shall be instructed in emergency procedures such as dealing with accidental acid spills.”

♦ Formaldehyde 29 CFR 1910.1048(i)(3)

“If there is any possibility that an employee’s eyes may be splashed with solutions containing 0.1 percent or greater formaldehyde, the employer shall provide acceptable eyewash facilities within the immediate work area for emergency use.”

Consensus applicable regulation

ANSI/ISEA Z358.1-2014 is a voluntary national consensus standard that OSHA refers employers to as a recognized source for guidance. It helps users select, install, operate and maintain emergency eye wash and shower equipment. The standard is divided into five sections and each section addresses minimum performance and use requirements, as well as installation, testing procedures, maintenance and training requirements. OSHA often uses ANSI/ISEA Z358.1-2014 as a guide during inspections and may elect to issue penalties based on non-compliance.

To ensure that eyewash stations and showers are always ready when needed, it is important that the requirements for test procedures and maintenance set forth in ANSI/ISEA Z358.1-2014 be followed. The requirements for testing and maintaining eye, eye/face washes and showers are based on the manufacturer’s instructions and ANSI protocols. Generally, the manufacturer’s instructions state that the devices should be inspected tested and the results recorded weekly. Individual owners’ manuals should be looked at for the specific manufacturer’s guidelines.

Determination of a corrosive material

Within the general guidelines, occasionally the question comes up as to whether OSHA requires eyewashes for anything other than injurious corrosive chemicals. In a May 5, 2004 letter of interpretation, OSHA states: “As the standard states, an eyewash and/or safety shower would be required where an employee’s eyes or body could be exposed to injurious corrosive materials. If none of the materials used in this work area is an injurious corrosive (as indicated by the Material Safety Data Sheet (MSDS) for each product), then an emergency eyewash or shower would not be required pursuant to 1910.151(c) and 1926(g)”

Corrosive material is present in many workplaces either by themselves or contained in other materials. It is a good idea to refer to several sources to determine if a chemical is considered a corrosive to OSHA’s definition as it applies to eyewashes.

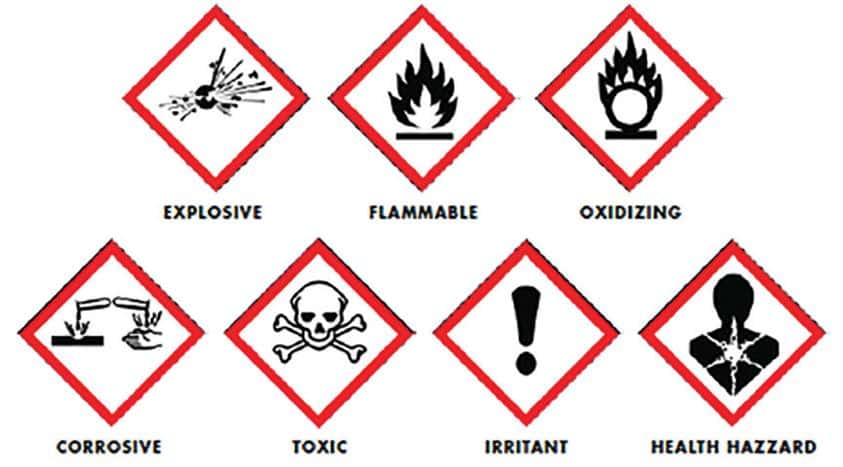

One of the easiest ways to identify if a chemical has corrosive properties is to use OSHA’s Hazard Communication Standard (29 CFR 1910.1200) and the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) as a guide. The universal symbols/pictograms used on labels and containers provide clear indications if a chemical is a corrosive.

Another source to identify if a chemical is corrosive is the Safety Data Sheet (SDS). Section 2 of the SDS will quickly provide the same information found on the shipped container label including the pictogram and precautionary statements. Section 9 of the SDS provides more details about the physical properties of the chemical including pH, which is the measure of how basic or acidic the chemical is on a scale of 0-14. A rating below seven is more acidic and above seven is more basic.

One other source to reference is the NIOSH pocket guide. The pocket guide presents key information such as pH in abbreviated or tabular form for chemicals or substance groupings that are found in the work environment.

View Emergency Equipment Product Solutions here>>

[via ISHN]