[via LabManager.com]

ANSI standard Z358.1 is detailed in terms of defining what is appropriate for safety showers and eyewash stations.

As lab managers and employees, we know that many inorganic chemicals (such as the mineral acids and alkalis) are corrosive to the skin and eyes. Likewise we are aware that many organic chemicals (such as acid halides, phenols, and so on) are corrosive and often toxic. Yet we Safety Guys are continually shocked by laissez-faire attitudes toward the use and maintenance of basic safety equipment by lab personnel, and the resultant unnecessary injuries.

One extreme example we constantly recall is the tragic UCLA accident just a few years ago, which resulted in a fatality from chemical burns.1 And we recently noticed a post on the American Industrial Hygiene Association pages for Lab Safety Chemical Exposure Incidents, where improper use of an eyewash resulted in a trip to the emergency room.2

The worker was using a fluorescent stain in the cytogenetics lab and felt something splash into his eyes. He was not wearing safety goggles or glasses. (D’oh!) Long story shortened, he flushed his eyes at the nearest eyewash, but they remained irritated and began to swell shut, necessitating a visit to the emergency room. Back at work a few days later, he noticed a coworker using the same eyewash to clean glassware and stainless steel trays, which were left resting in the sink in a cleaning solution. (What?!)

What does OSHA say?

In 29 CFR 1910.151 Medical Services and First Aid, it states that “where the eyes or body of any person may be exposed to injurious corrosive materials, suitable facilities for quick drenching or flushing of the eyes and body shall be provided within the work area for immediate emergency use.”3 OSHA doesn’t provide more specifics regarding what constitutes “suitable” or how “immediate” is defined. So how do we know if we are meeting the intent of the law?

Fortunately, we have the American National Standards Institute (ANSI), and their consensus standard Z358.1, last updated in 2014. This ANSI standard is very detailed in terms of defining what is appropriate for safety showers and eyewash stations. In fact, OSHA uses this reference as a guide when inspecting facilities. So let’s review what is “recommended” for acceptable safety equipment.

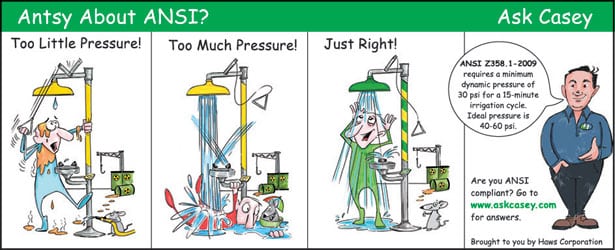

Safety shower specs

Begin by checking your facilities for the proper hardware, as recommended by Z358.1. Rest assured that OSHA will, should one or more agents show up for an inspection. For safety showers, the shower head must be capable of flowing 20 gallons per minute (gpm) at 30 psi and producing a 20-inch diameter spray pattern at 60 inches above the surface where the user stands. The center of the sprayhead pattern should be at least 16 inches from any wall, door, or obstruction. It is recommended that the shower head be mounted between 82 and 96 inches off the floor, with the valve no higher than 69 inches.

Eyewash specs

Eyewash stations target just the eyes and therefore have a lower flow requirement. ANSI Z358.1 recommends a flow of 0.4 gpm also at 30 psi. The nozzles should be at least six inches from any obstruction and mounted between 33 and 45 inches above the floor. An eyewash gauge should be used to verify and test the flow pattern.

Requirements for both

Both safety showers and eyewash stations must be able to provide the recommended flow for at least 15 minutes. This usually translates into having the equipment plumbed in with hard connections to the water supply. For example, a quick calculation for the safety shower at 20 gpm yields 300 gallons needed. Self-contained or personal wash devices are allowed, but they are considered supplemental units that can provide immediate flushing while transiting to the permanent fixture.

If the local climate presents potential for freezing conditions, the equipment must be designed to avoid freezing or protected against that situation. Activation valves must open within one second and remain open until intentionally closed or turned off. It goes without saying that these safety devices should be constructed of corrosion-resistant materials.

The 2014 update to Z358.1 added two important criteria. The first is that the requirement for tepid water is now defined as having a temperature of between 60 and 100 degrees Fahrenheit (15 to 37 degrees Celsius). The second change addresses simultaneous operation for combination units. This means that if you have a drench shower combined with an eyewash station, both devices must provide adequate flows and be fully operable at the same time.

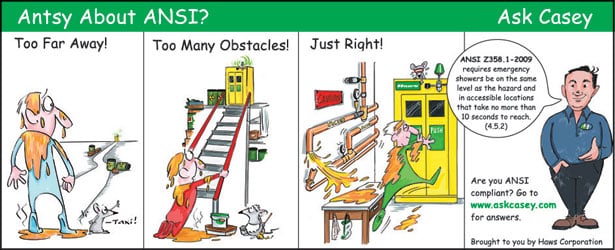

Finally and most importantly, consider the location of equipment. We know you have the 10-second rule etched into your brain, as that is the most critical element when it comes to safety showers and eyewashes. This means that travel to the unit should be under 10 seconds for all hazardous areas that need this equipment. This equals about 55 feet. In addition, the drench shower or eyewash must be on the same level as the hazard and have a clear path for travel. We recommend painting or marking the floor area underneath the shower to help keep it clear. Z358.1 also recommends equipment be installed in a brightly lit area and marked with a highly visible safety sign.

Maintenance and training

The last thing you want is to rush to the eyewash or shower, only to be drenched with nasty, sediment-laden water. ANSI recommends flushing all equipment weekly to verify proper flow, and clearing the plumbing of any deposits. If your facility does not have floor drains installed, remember to bring a large, plastic trash can to catch the water. The weekly flushing can also provide a great training opportunity to refresh the operation and travel paths for your employees.

If you want to find out about the ANSI/ISEA Z358.1 significant requirements, attend our free 1-hour webinar on September 21st, 2017.

Register now and become subject matter experts of your emergency eyewash and shower equipment including weekly and annual testing. Request a certificate of attendance after the webinar.

This free webinar will cover:

• ANSI/ISEA Z358.1 significant requirements

• Important 2014 revision highlights

• Compliance best practices

• Live Q&A

WHAT: All You Need to Know About ANSI Z358.1 Webinar

WHEN: September 21, 2017 from 10am-11am PT / 1pm-2pm ET

PRESENTER: Justin Dunn, Product Specialist/Trainer and Samantha Hoch, Marketing Strategist

HOW: Register for free

Attendees will receive these complimentary materials after the webinar:

• OSHA white paper

• Weekly and Annual ANSI Checklist

• Access to On-Demand Webinar

References

1. “tert-Butyllithium Claims Fellow Chemist at UCLA,” Chemistry Blog, January 19, 2009, http://www.chemistry-blog.com/2009/01/20/tert-butyllithium-claims-fellow-chemist-at-ucla/.

2. “Lab Safety Chemical Exposures Incidents,” American Industrial Hygiene Association, https://www.aiha.org/get-involved/VolunteerGroups/LabHSCommittee/Incident%20Pages/Lab-Safety-Chemical-Exposures-Incidents.aspx.

3. “Medical Services and First Aid,” US Department of Labor, Occupational Health and Safety Administration, https://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=STANDARDS&p_id=9806.

ANSI Compliance, Safety & Health for Food ProcessingFrom the oil industry to mining, agriculture to research, any working environment that puts employees in close proximity to occupational hazards such as potentially harmful chemicals must make workplace safety a priority. The food processing, meat packing, and poultry processing industries are no exception.

INDUSTRY RISKS

In addition to physical hazards like high noise levels, cuts, and musculoskeletal disorders, exposure to substances like ammonia, carbon dioxide and carbon monoxide can pose another risk to employees in the meat packing and food processing industries.

In March of 2016, OSHA fined a Texas-based poultry plant for allegedly allowing the release of anhydrous ammonia, a gas commonly used in significant quantities as a refrigerant across a variety of food processing facilities. This colorless gas, classified as hazardous by the OSHA Hazard Communication Standard, is known to be highly irritating, with a very sharp, suffocating odor. Immediate health effects of exposure to anhydrous ammonia include:

• Burning of the eyes, nose and throat

• Coughing and choking

• Swelling of the throat and/or chemical burns to the lungs

Prolonged exposure can lead to eye damage, severe burns, and even death.

Another OSHA violation occurred in December 2012 when a food manufacturing facility did not provide an emergency shower or eyewash in the immediate vicinity of a forklift battery charging station.

MEETING THE STANDARD

Immediate first aid for exposure to anhydrous ammonia or battery acid includes providing fresh air and immediate flushing with water for no fewer than 15 minutes. Safety data sheets for many chemicals require that eyewash stations and safety showers are close to the workstation location as a protective measure. And OSHA 29 CFR 19010.151(c) states “where employees were exposed to injurious corrosive materials, suitable facilities for quick drenching or flushing of the eyes and body.” This kind of emergency response access necessitates appropriate safety equipment and proper employee training – hallmarks of industry guidelines set forth by the American National Standards Institute (ANSI).

ANSI Z358.1 is a comprehensive guideline that outlines specific parameters for the appropriate design, installation, performance, certification, use and maintenance of emergency eyewash and shower equipment across a range of industries. Failure to comply with all aspects of ANSI Z358.1 not only puts employees at risk, it opens a facility to potential liabilities and penalties. When working with chemicals, such as anhydrous ammonia, taking preventative measures is your safest bet. By supplying the appropriate emergency eyewash and shower equipment, you’ll be able to prevent further injury as well as reduce the risk of OSHA and ANSI non-compliance.

Download this white paper to share or save>>

Safety Tip: Equipment Location Installation – Defining Obstructions

If it only takes a single hop, skip, or jump to get to a piece of emergency equipment from any location in your workplace, your workplace is in compliance with one of the ANSI Z358.1 requirements. A walk to the nearest emergency equipment location should total less than 10 seconds and be obstruction free. But what defines obstruction?

Our definition of obstruction is not limited to obstacles or barriers (pipes, closed doors), it also includes impediments or delays (stairs, curbs). An obstruction would be anything that impedes access to the equipment by increasing the time to reach the unit or causing further injury. There are obvious obstructions that would clearly delay access to an emergency response shower unit in 10 seconds or less but other hazards could not only cause a delay but could cause further injury. Stairs (because of the requirement to be on the same level as the hazard), piping, boxes, cabinets, trash, office furniture, etc would all be considered a clear obstruction and should be cleared from the equipment area.

Doors are specifically discussed in the appendix of the standard which is not part of the standard but serves as a guide. The standard states that if a door is used, it must open in the direction towards the shower. Yet, a typical door that opens with a handle would not be accepted per the appendix. Ideally a shower unit that is enclosed will have saloon-type doors that swing in and out for access and don’t require the added motion and added time of twisting a handle. If a door is needed for privacy or temperature control, it must open in the direction of the shower without any type of handle to open the door.

Considerations for equipment location should go into effect before purchasing and installing. It’s important to keep in mind where each individual piece will be stationed and how many pieces will need to be purchased to make sure you are creating a predictable, reliable, stable environment to reduce any unnecessary emergency response problems or delays.

To stay up-to-date on additional safety tips, watch the ”Haws Presents ANSI Z358.1 Answered” on-demand webinar by clicking here.

ANSI Z358.1 FAQ’S: eyewash or eye/face wash? OSHA or ANSI?Casey Hayes, Director of Haws Integrated™, is our go-to expert for questions on ANSI Z358.1. For your quick reference, Casey has responded to your most frequently asked questions to help you stay up-to-date on ANSI compliance.

What is the difference between an eye/face wash and just an eyewash?

An eyewash is specific to eyes, and the water flow rate is designed to hit only the eye surface. It is imperative that the eyewash temperature be 60° – 100° F and have a continuous flow for a full fifteen minutes. Having an eyewash with the right requirements will not only make a difference between temporary blindness and permanent blindness, but increase productivity. Nearly 2,000 eye injuries occur each day in the workplace and with only half of U.S. workplaces in compliance, the cost of an injury can be significant.

An eye/face wash will cover the eyes and a portion of the face. In addition, an eyewash has a .4 gpm minimum flow rate and an eye/face wash has a 3.0 gpm minimum flow rate.

Eye/face washes are beneficial because it’s rare that a victim only has a chemical hit the eye area so using an eye/face wash to flush more of the exposed area will only increase and enhance the emergency response.

Does OSHA use the ANSI standard?

OSHA requires the employer to provide suitable facilities for quick drenching or flushing of the eyes. While OSHA has not formally adopted ANSI Z358.1, they refer employers to the standard as a source of guidance. In other words, OSHA agrees to enforce safety standards presented by ANSI, while ANSI acts as an assistant to OSHA with safety and health standards. ANSI is recognized as an approval agency of voluntary national consensus standards.

It is the employer’s responsibility to assess the particular conditions related to the needs of the site to ensure the eye/face wash and shower unit(s) provide suitable protection for employees.

For more questions regarding ANSI Z358.1, read our white paper here.

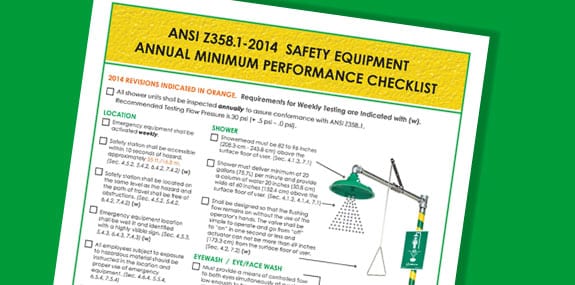

ANSI Z358.1 FAQ: What is the Weekly Test vs. the Annual Test?Are you unsure of when you should test the emergency showers and eyewashes in your facility? Do you know the difference between the weekly and annual testing requirements? In certain cases, a full 15-minute drench period is not required, however it is important to know what is required on a weekly basis versus annually.

ACTIVATE WEEKLY

Per the ANSI Z358.1 standard, you are required to activate the emergency equipment weekly to verify operation and to ensure there is a flushing fluid supply and clear the supply line of any sediment build-up that could prevent the flushing fluid from being delivered due to stagnant water.

How long do you activate for? ANSI states the duration of the weekly activation depends on the amount of water contained in the unit itself and all sections of pipework that are not a part of a constant circulation system, also known as the “dead leg” portions. The goal of the weekly activation is to flush out the stagnant water in the dead leg completely.

TEST ANNUALLY

All emergency eyewashes, eye/face washes, showers and combination units are required to be fully inspected annually to ensure conformance with the installation section of the Z358.1 standard for that type of equipment. The following some of the requirements that need to be met for the annual test:

- The equipment must be assembled and installed in accordance with the manufacturer’s instructions, including flushing fluid delivery requirement.

- Equipment must be accessible within 10 seconds, located on the same level as the potential hazard, and must be free of obstructions that may inhibit immediate use.

- Must be identified with well-lit, highly visible signage.

- Equipment must be connected to a supply of flushing fluid that can produce the required flush time of a full 15 minutes.

- Where the possibility of freezing conditions exists, equipment must be protected from freezing or freeze-protected equipment must be installed.

- Must deliver tepid flushing fluid for the full 15-minute drench period.

- Equipment must go from “off” to “one” in one second or less.

- Must provide a controlled flow of flushing fluid at a velocity low enough to be non-injurious to the user.

How long do you activate for? As stated above, you need to ensure the equipment is is delivering tepid flushing fluid for a full 15 minutes.

For full detailed information on the ANSI Z358.1 requirements for Emergency Eyewashes and Showers, watch the FREE on-demand webinar HERE.

For more ANSI resources such as a testing checklist, click here.

Things to Consider When Choosing Emergency Showers and EyewashesBy Jim Schneider, Plumbing Engineer Magazine

In many work environments, properly installed and utilized emergency fixtures can mean the difference between a minor injury and a major injury or worse. When health and safety is on the line, it’s important to make sure all necessary considerations are taken into account when facilities are being designed and built.

Plumbing Engineer recently spoke to Margo Mee, Product Manager at Haws Corp., about things to think about when choosing emergency fixtures and systems.

PE: Can you tell us about Haws’ background with emergency fixtures?

MM: Haws invents, manufactures and builds drinking fountains and standardized and customized emergency response products. For all our products, we continually focus on quality, service, reliability and complete solution support just as we have done for more than 100 years.

PE: What are some of the primary considerations when selecting emergency fixtures?

MM: When researching and purchasing a unit, a product that mimics medical protocols, offers full ANSI compliance in all scenarios, and really considers victim needs and comfort is the ideal solution to offer a complete emergency response system.

PE: From the manufacturing side, what are some of your primary considerations when designing and making emergency fixtures?

MM: Victim comfort for maximum results is the primary consideration when designing emergency products, but it also important that the product is reliable and durable. Our quality products are thoroughly tested and evaluated at numerous points during design and build.

PE: What kinds of challenges do you face with emergency fixtures? How do you deal with those challenges?

MM: Because they are not used frequently, a lot of facilities will place their importance on the back burner and not evaluate if their site’s needs have changed, if the install location is still ideal, if the units even work or are ANSI compliant. The best way to address these common issues is through continuous education. We offer onsite facility testing and evaluation, detailed informational videos, and on-demand and live webinars with access to our engineering team.

PE: Has the standard and market for emergency fixtures remained pretty constant, or are there many updates and changes?

MM: The last major change in the standard was in 2009. That revision included a definition for tempered water and from there you could see product changes. The market itself continues to grow as people are more educated and are asking the right questions and demand that their site provide the ideal solution. Manufacturers are held accountable for providing a reliable product and if they can’t adhere, their products are being replaced.

PE: Are there any trends or updates to the standard you see on the horizon?

MM: We would hope to see a revision in the next 6-12 months.

PE: You wrote a white paper about exceeding the ANSI Z358.1 Standard. Can you tell us a little about the baseline of the standard itself?

MM: The ANSI Z358.1 Standard defines emergency eyewash and shower design, location, testing, activation, and temperature requirements for proper functionality and usage. Simply providing emergency eyewash and shower products is not enough. Facilities must inspect, test, and monitor emergency equipment system readiness and performance. Even though the most current ANSI Z358.1 standard now dates to 2009, most emergency eyewash and shower units across North America still do not yet comply with these significant provisions.

PE: Why should end users be looking to exceed the standard?

MM: Treat the situation as if you could be a victim. You would only want the best solution that performs as required as well as provides an additional benefits so the emergency response tool doesn’t cause further injury.

PE: How can products and systems exceed that standard?

MM: Haws products go beyond the minimum performances of emergency eyewashes and showers requirements by keeping the victim in mind when in an emergency situation. Haws products include victim comfort with water pressure and flow, effective flushing with the use of our unique AXION directional flow, appropriate and recognizable color coding, and temperature controls to encourage proper usage. In addition, Haws offers a variety of educational tools to help educate and train users.

Preparation: The Best Guard to an Emergency

Do you know the protocol to flushing hazardous chemicals off of your body in an emergency? It’s always a good rule of thumb to be knowledgeable on how to properly execute safety shower and eyewash performance in an emergency situation. Take the time to get to know the mechanics of the emergency equipment in your facility before an accident takes place. Casey Hayes, director of Haws Integrated™, recommends the following:

- Get a proper training session on emergency equipment. Be aware of the location of the unit and how long it takes to arrive at the unit from your work space.

- Confirm that it should not take more than 10 seconds to arrive to the emergency equipment.

- Upon arrival to the shower, pull lever and remain in shower for a full 15 minutes. This is to ensure the prevention of chemical absorption while it also helps to cool burns and prevent hypothermia.

- When using an eyewash or eye/face wash, hold eyes open during the entire 15 minute flushing period.

- In some cases, it may be appropriate to have a partner with you during the state of emergency. If you work alone, you may not have the opportunity to have someone assist you. We recommend that if you are in a state of shock, have a co-worker assist you to the emergency shower and or eyewash station. If you are saturated in chemicals, it is best not to expose anyone else and to proceed to the emergency station alone.

- Always go to the emergency room following the use of the emergency shower and/or eyewash.

Furthermore, it’s essential to have functional emergency showers and eyewashes throughout your facility. Refer to our previous blog post ANSI Z358.1 FAQ: What is the Weekly vs. Annual Test for a break down on when it is appropriate to perform each test. We also offer a free webinar on the requirements for emergency eyewashes and showers. Click here to watch.

ANSI Z358.1 DEBATE: “1-Touch” vs. “1-Second” Activation

The ANSI Z358.1 Standard (American National Standard) mandates that proper eyewash activation – which describes a unit going from “off” to “on”- shall take one second or less. This requirement has held true since the inception of the ANSI Standard in 1981 and throughout all revisions including 1990, 1998, 2004, 2009 and 2014. Despite this, the myth that the eyewash must go from “off” to “on” in one motion continues to be inaccurately shared.

To quote the 2014 Standard: “The valve shall be simple to operate and shall go from “off” to “on” in 1 second or less.”

This disconnect in awareness of the activation requirement has come up especially pertaining to faucet-mounted eyewashes where it is required for the user to turn on the water supply and then activate the unit, hence a two motion activation.

Specifically, the Haws® AXION® eyePOD® faucet-mounted eyewash has proven through testing that it meets the “off to on in one second or less” activation requirement.

Mounting easily to standard faucets, the AXION eyePOD provides healthcare offices, laboratories, schools, and even households with medically consistent inverted eyewash flushing technology.

As seen below, a simple rotation of the unit transforms normal faucet capabilities into a fully-functioning, ANSI compliant eyewash station.

Medically Superior Response®

The trademarked inverted water streams gently flush contaminants away from sensitive glands and ducts that surround the eye. The added protection to these valuable organs helps reduce against unnecessary injury.

Click here to learn more about the AXION eyePOD.

If interested in pricing information or receiving a quote, click here.

For more information on the ANSI Z358.1 Standard for emergency showers and eyewashes, visit our ANSI Resources page.

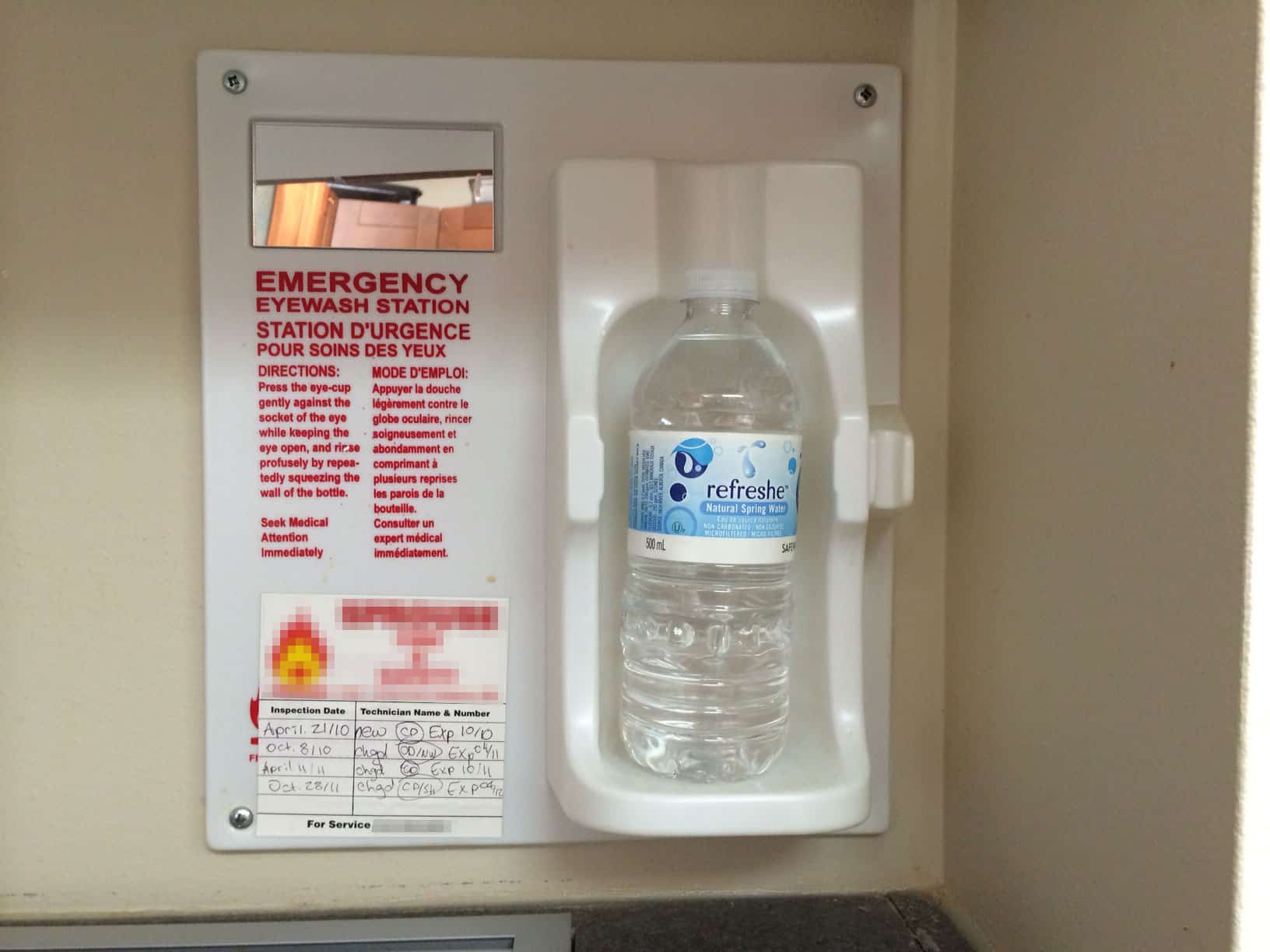

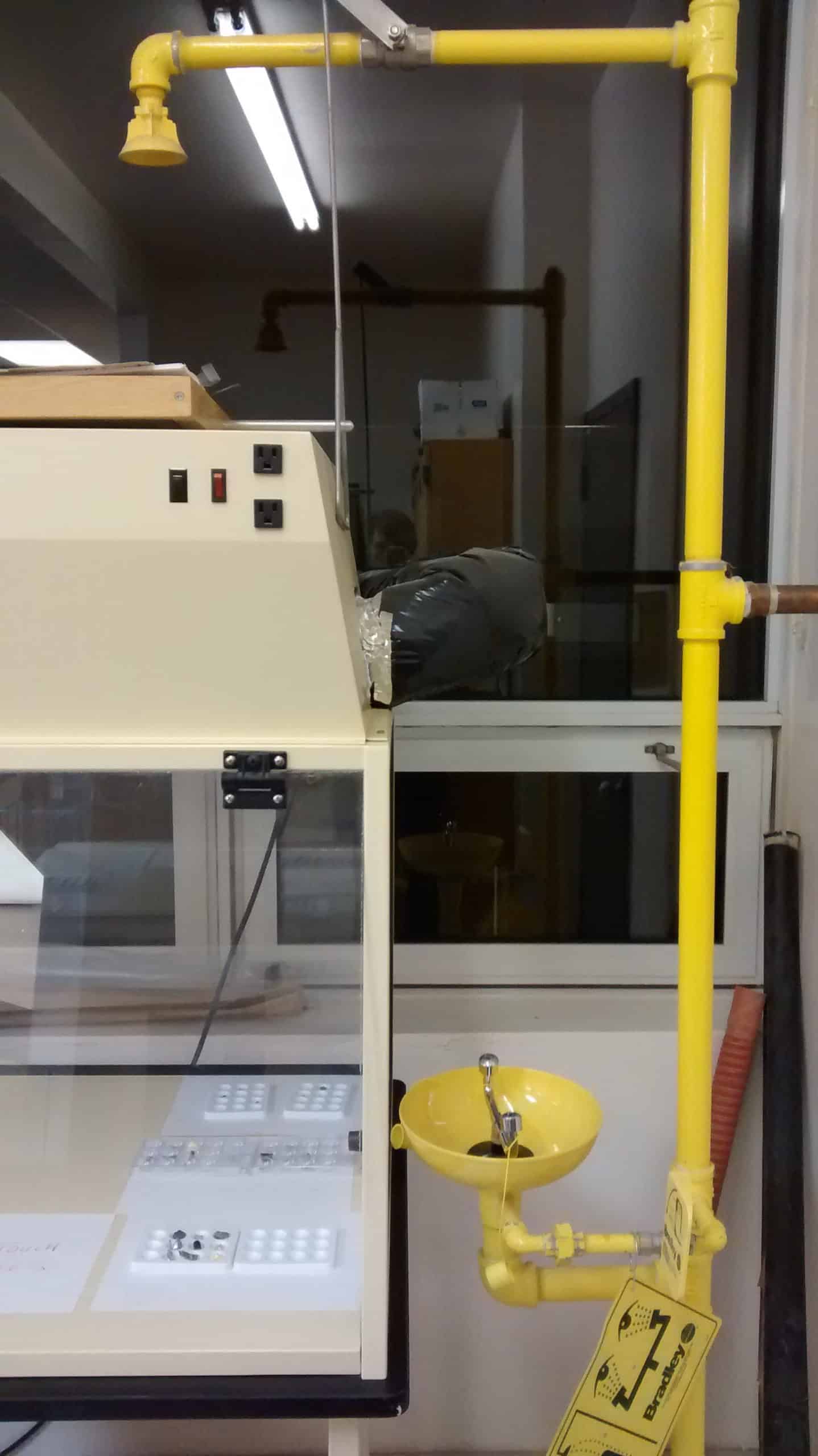

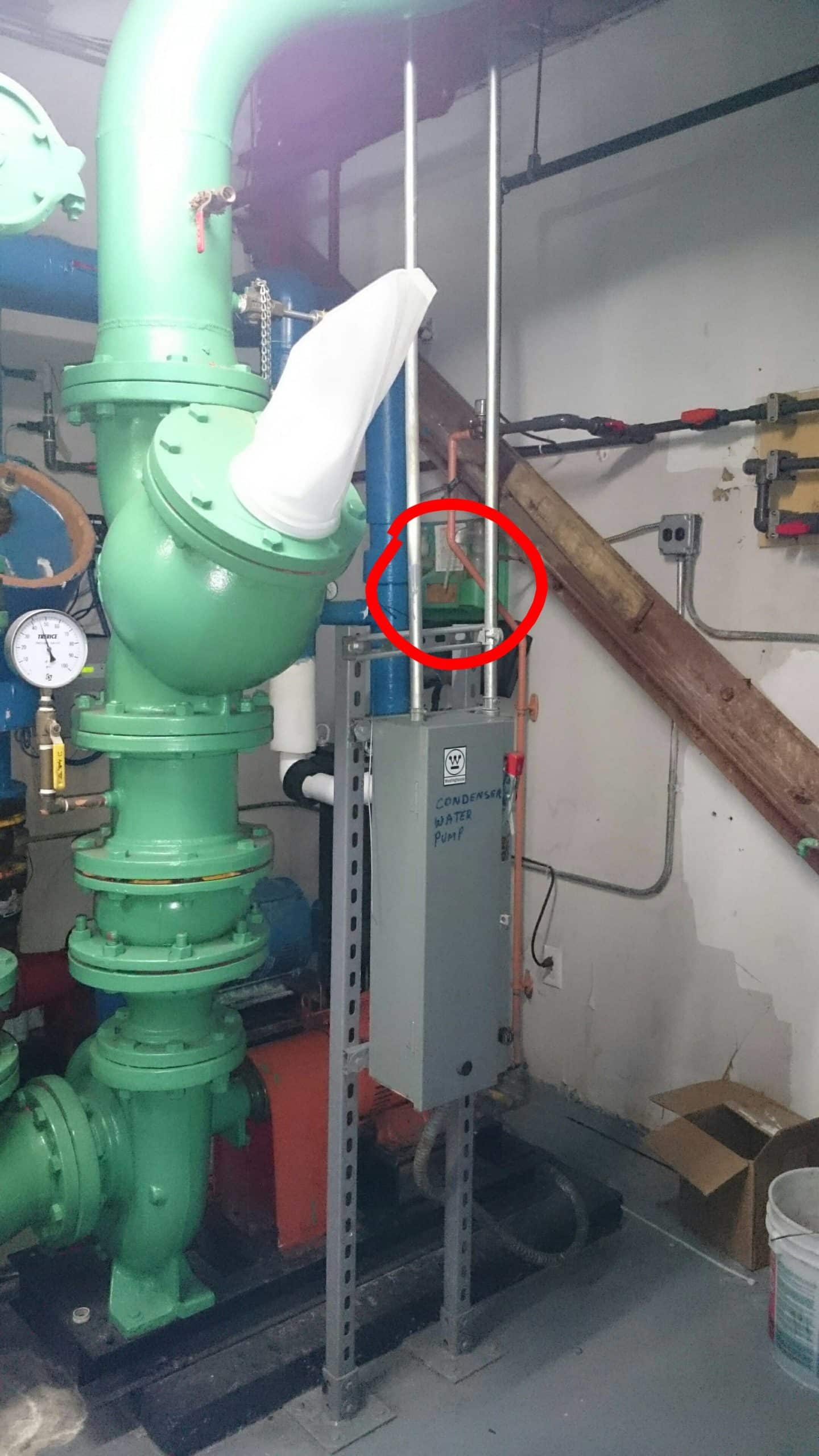

Monday Tip: Emergency Eyewash “No-No’s”It is interesting to see what some facilities consider to be sufficient in regards to providing proper emergency shower and eyewash equipment. Below are just a few of these not-so-compliant “solutions”.

Not only does this risk potential fines from OSHA for not complying with the ANSI Z358.1 Standard, but it also put workers, students, etc. at risk of not having proper functioning equipment to use in the event of an emergency.

Ummm… not quite an equivalent.

I wonder where the user is supposed to stand?

Ever seen a dual-functioning water cooler and eyewash station? Yeah, neither have we.

Can you spot the eyewash station?

Our tip: When installing an eyewash or shower unit, test out an emergency scenario to make sure you are giving a victim the required distance and access. Choose the path of least resistance to guarantee a victim the best treatment possible and to reduce potential injury damage.

For more information on ANSI installation requirements, visit www.hawsco.com/ANSI .

FAQ: Tepid Water for Emergency Showers & EyewashesBelow are some frequently asked questions regarding the ANSI Z358.1-2014 requirement of providing tepid water for emergency showers & eyewashes. Tepid water is defined as flushing fluid between 60°F- 100°F (16°C- 38°C).

If the area is typically 70°F (21°C), is the use of a 300 gallon storage tank an acceptable means of providing tepid water for emergency showers & eyewashes?

Yes and no. Theoretically you could fill a tank without an immersion heater and allow it to reach equilibrium with the ambient environment (70°F [21°C]), and provide tepid water. The issue is that you will need more water than 300 gallons to provide 15 minutes of tepid water because you will have to account for the shower (20 gpm) and eyewash (1 gpm) or eye/face wash (3-5 gpm depending on manufacturer). Based on these, you will require as a minimum 315 gal at a minimum assuming 100% usage for a shower/eyewash or 345 gal minimum assuming 100% for a shower and eye/face wash combination. If this is a self-contained unit, you could do this but would have to add a bacteriostatic solution, have at a minimum a 400 gal tank, and some means for delivering the water (air cylinders or pump). Haws Integrated can provide a plug and play system of this type.

The other thing to consider is that you are now holding water at a temperature that is much more prone to bacterial growth. When Haws Integrated designs a tepid water system, we will hold the water at a minimum of 145°F (62.8°C), but more typically at 165°F (73.9°C), which prevents the growth of bacteria. Also critical to eliminating bacterial growth is the flushing of the showers and piping on a weekly basis. Without a heater, the recovery time could be significant.

If you have cold water plumbing and adequate pressure, then I would recommend that you use a hot water tank system along with a mixing valve to get tepid water for a potable water system.

How do you provide cool water for tempering valves? (e.g. cooling tower water exchanger, air finned cooler, etc?)

The cool water comes from the potable water supply, and is assumed to be below 60°F (16°C). The water will be combined with the hot water in the storage tank to produce tepid water for emergency showers & eyewashes.

My facility uses 65°F (18.3°C) as the low end temperature for Legionella growth and requires mixing valve to pass 160°F (71°C) for shock treatment of tepid systems, but you recommended 80-85°F (26.7-29.4°C)?

Legionella growth range is between 68°F – 122°F (20-50°C). Most potable water coming into a tepid water system is below 60°F (16°C). On the hot water side the water is held at 165°F (73.9°C) or above, therefore lowering the possibility of Legionella growth. There is no mixing valve on the market designed for safety showers that can pass water at 165°F (73.9°C) for shock purposes. This is a dangerous scenario for safety equipment. A process would need to be implemented to ensure the safety equipment could not be used until the piping temperature was reduced to below 100°F (38°C).

ANSI Z358.1 – 2004 code, clause B6 suggested 60°F (16°C) tepid water is suitable as the lower limit of tepid water. Is there a change of concept between 2004 and 2014?

No, there is no change in the tepid water requirement. However, the 2009 and 2014 standards moved the tepid water ranges of 60°F to 100°F (16°C- 38°C) from the appendix to the main section of the standard. We recommend that the temperature be in the middle of the range for user comfort and promoting 15 minutes of usage.

Explore our Tempered Water Solutions

To find out when the next FREE webinar on the ANSI Z358.1 Standard is sign-up for Haws E-Newsletter.

Everything ANSI You Will Ever Need!MARCH 2015 NEWSLETTER

Live ANSI Z358.1 Webinar: Your Complete Guide to Tepid Water

The American National Standards Institute (ANSI) introduced tepid water as an emergency wash requirement in 2009 as an update to the ANSI Z358.1 Standard.

In this FREE webinar, we’ll provide insight into what tepid water is, ANSI requirements for tepid water, and tepid water solutions.

WHAT: Webinar, “Well-Tempered: Your Complete Guide to Tempered Water”

DATE: Wednesday, April 23rd

TIME: 10:00 am PT / 1:00 pm ET ( 1 hour )

Presenter: Casey Hayes, Director of Haws IntegratedTM

ANSI Resources Page with Updated Literature

As the ANSI Z358.1 Standard has updated to its newest 2014 version, we have updated our ANSI resources to include the changes. These useful pieces include:

CHECKLIST: ANSI Z358.1 Checklist for Safety Eyewash and Shower Units ( Spanish and French versions are available)

POSTER: ANSI Z358.1 Large Checklist Poster

WHITE PAPER: ANSI Z358.1 Simplified – Your Checklist for Emergency Eyewash

and Shower Compliance

ACCESS YOUR ANSI LITERATURE HERE»

On-Demand Webinar: Your Simplified Guide to ANSI Z358.1-2014

An ANSI Z358.1-2014 Standard for Emergency Eyewash and Shower Equipment update was introduced in January 2015.

In this on-demand webinar recording, we provide insight into these new ANSI requirements for:

- Emergency Eye/Face Washes

- Emergency Combination Units

- Emergency Drench Showers

- Tepid Water

- Best Practices

CLICK HERE TO WATCH»

VIDEO: How To Test Your Emergency Equipment

Our ANSI Z358.1-2014 Compliance video is a great visual resource, going through step-by-step testing procedures for your emergency showers and eyewashes, helping to ensure ANSI Z358.1 Standard compliance.