What are portable eyewash stations?

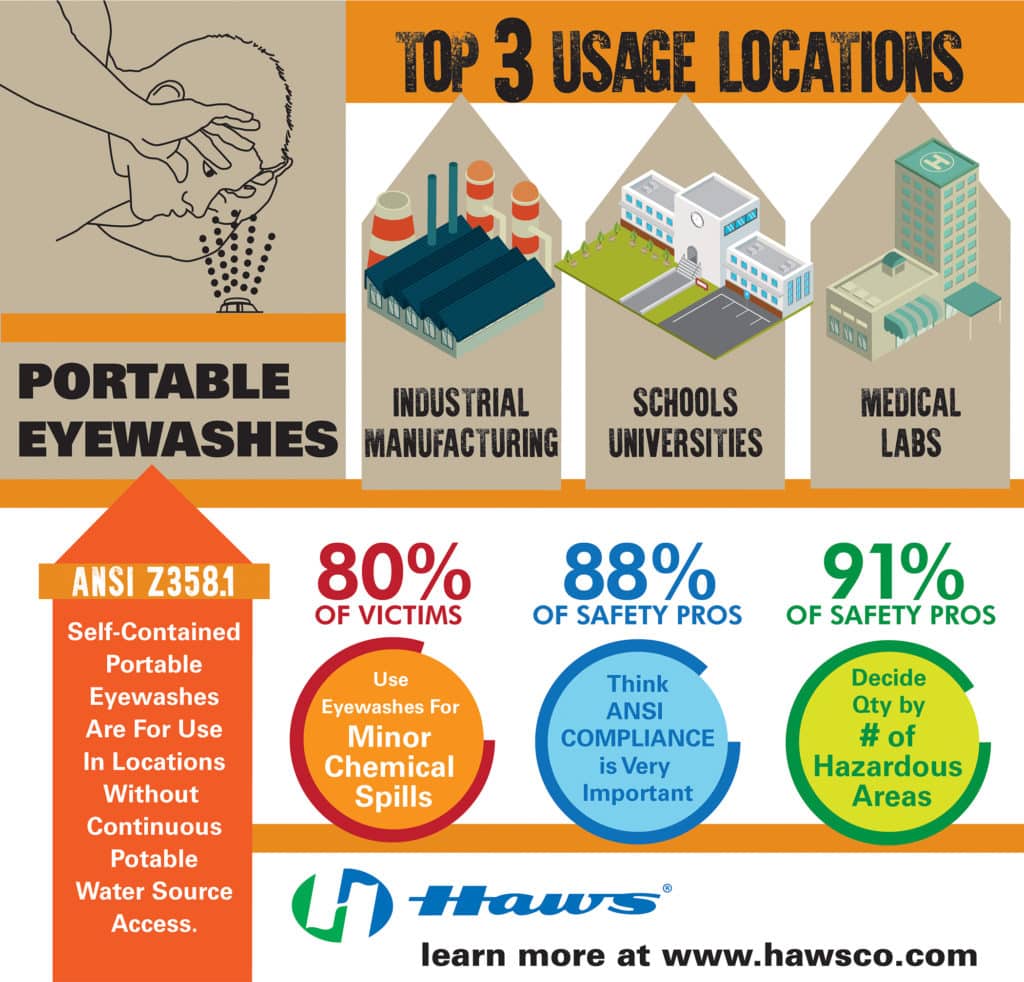

A portable emergency eyewash is a self-contained ANSI Z358.1 compliant emergency response product that is needed for locations without access to water and can be moved at a moments notice to meet the rapidly evolving needs of a chemical, manufacturing, or construction environment.

When is a portable eyewash station needed?

A portable emergency eyewash can be used anywhere an emergency eyewash system is needed but does not have access to a continuous source of potable water. The advantage over plumbed units is the mobility feature. This allows safety professionals to relocate the equipment as needed to stay compliant with ANSI and OSHA emergency equipment distance requirements.

Global Composite Supplier Chooses AXION® to Put Safety First

As a worldwide leader in the manufacturing of resin chemicals, Alpha Owens-Corning (AOC) understands the value of putting safety first.

When one of the North American AOC facilities needed to upgrade aging safety equipment, the decision fell to Catherine Sprigg, Environmental Health and Safety Coordinator at the Lakeland, Florida plant.

After seeing the Haws AXION® MSR eye/face wash and shower technology in a safety supplier catalog and at a trade show, the decision was easy.

After seeing the Haws AXION® MSR eye/face wash and shower technology in a safety supplier catalog and at a trade show, the decision was easy.

AOC retrofitted existing competitive safety equipment with medically-superior AXION inverted-flow technology. “They were easy to install,” she says. “A quality product at a reasonable price.”

Read the full case study here>>