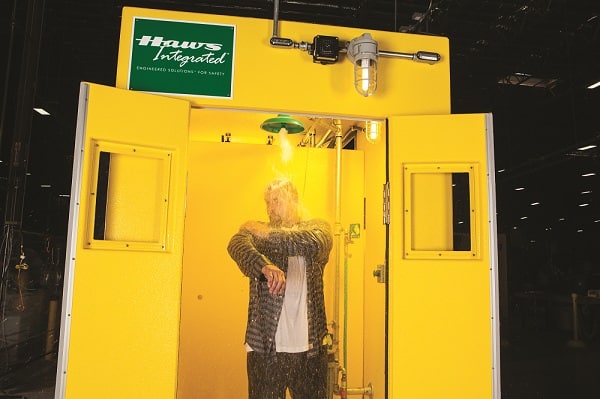

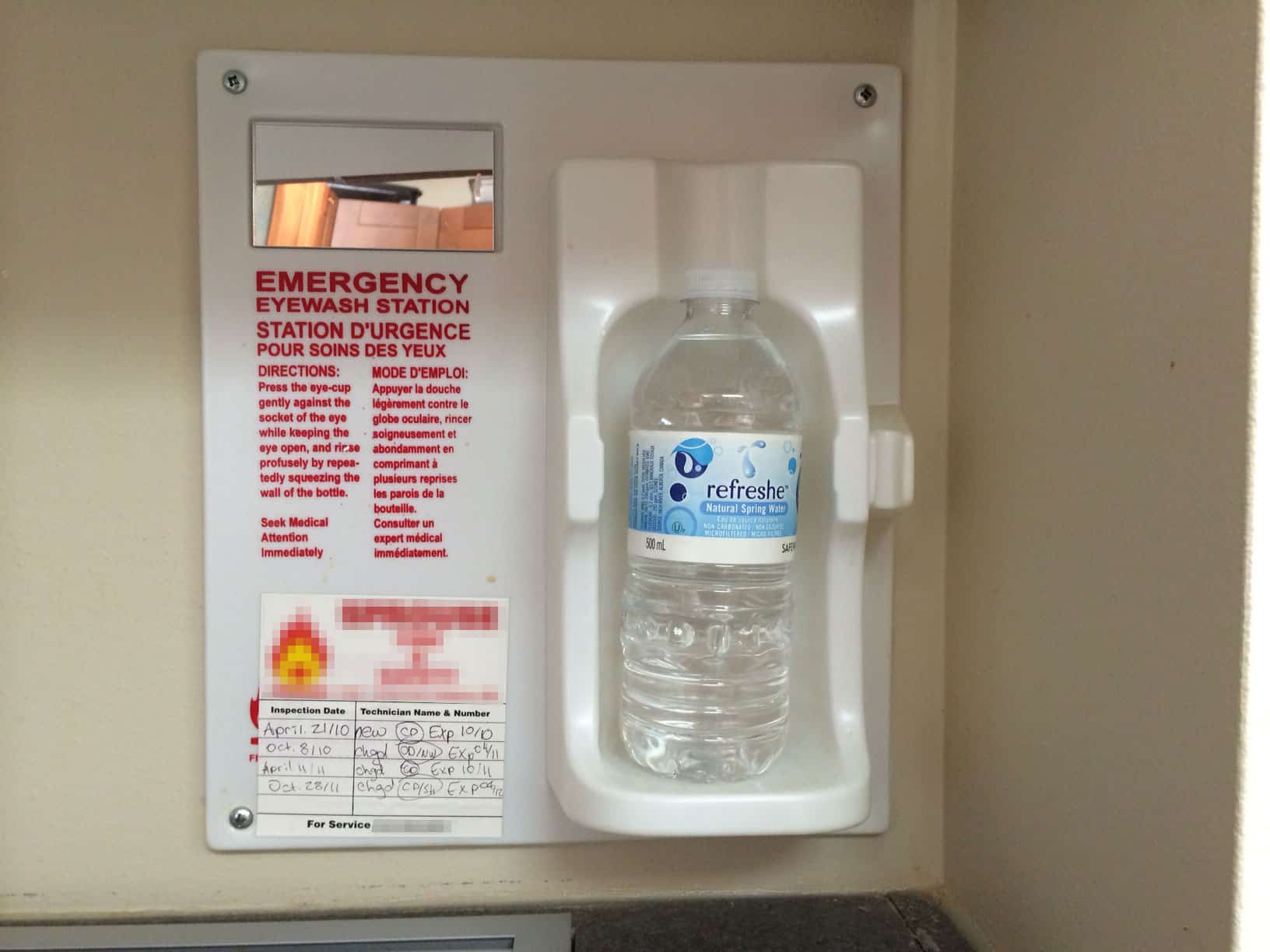

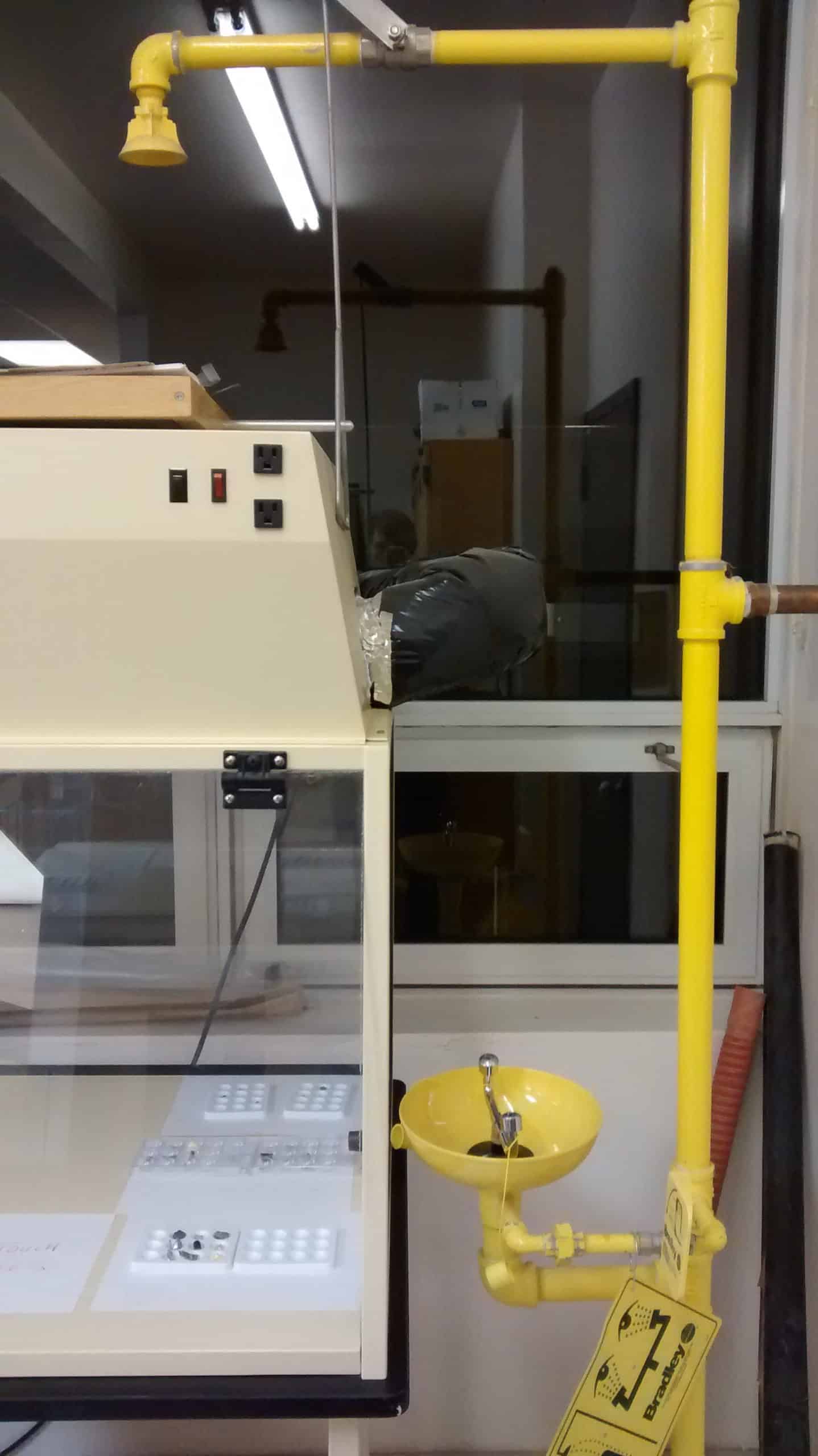

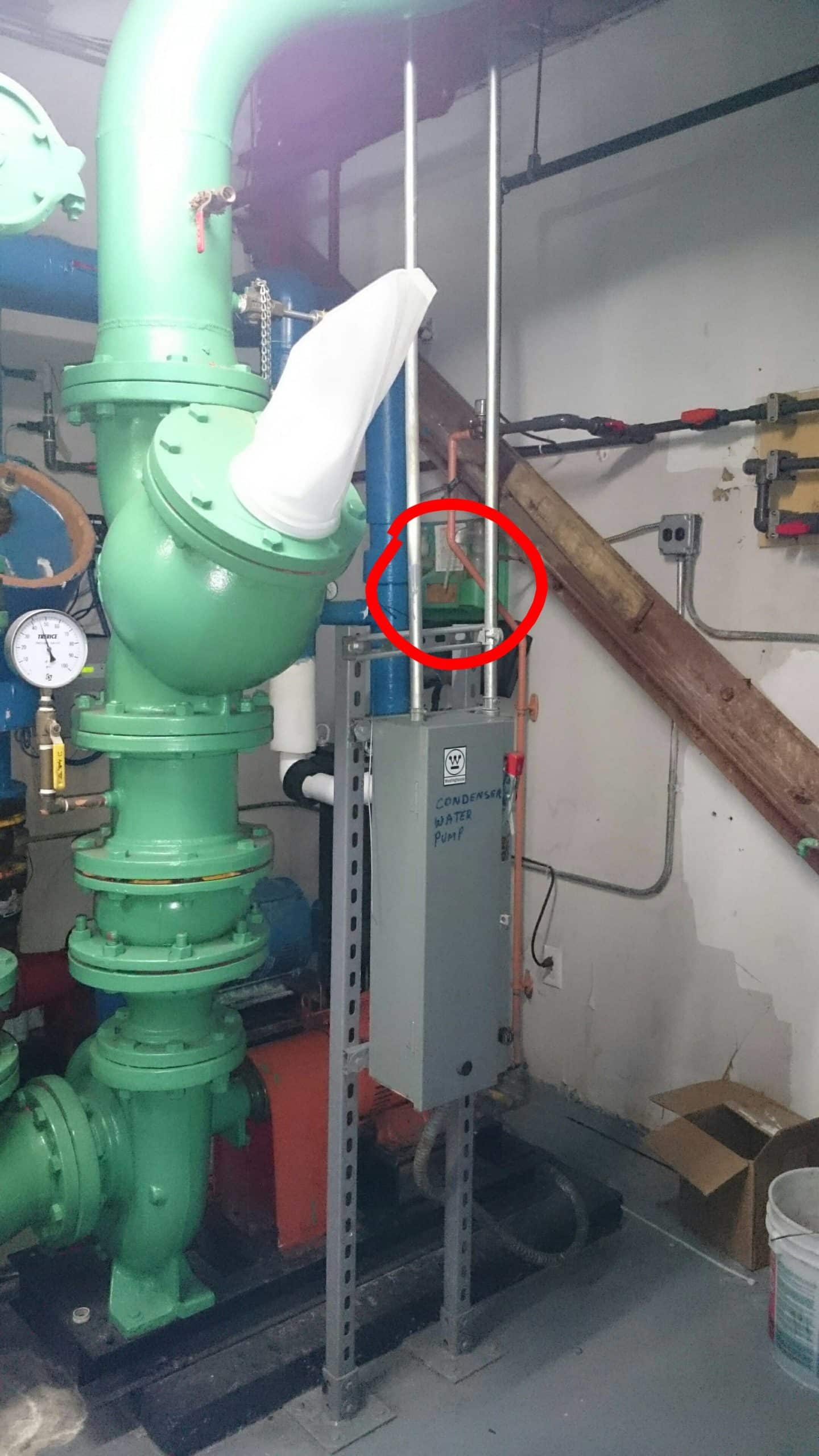

It is interesting to see what some facilities consider to be sufficient in regards to providing proper emergency shower and eyewash equipment. Below are just a few of these not-so-compliant “solutions”.

Not only does this risk potential fines from OSHA for not complying with the ANSI Z358.1 Standard, but it also put workers, students, etc. at risk of not having proper functioning equipment to use in the event of an emergency.

Ummm… not quite an equivalent.

I wonder where the user is supposed to stand?

Ever seen a dual-functioning water cooler and eyewash station? Yeah, neither have we.

Can you spot the eyewash station?

Our tip: When installing an eyewash or shower unit, test out an emergency scenario to make sure you are giving a victim the required distance and access. Choose the path of least resistance to guarantee a victim the best treatment possible and to reduce potential injury damage.

For more information on ANSI installation requirements, visit www.hawsco.com/ANSI .

FACT: 88% of Emergency Showers and Eyewashes Are Not ANSI CompliantAccording to Occupational Health and Safety “The first 10-15 seconds after exposure to a hazardous substance, especially a corrosive substance, are critical. Delaying treatment, even for a few seconds, may cause serious injury. Emergency shower and eyewash stations provide on-the-spot decontamination. Emergency shower and eyewash stations are a necessary backup to minimize the effects of accident exposure to chemicals.”

The American National Standards Institute (ANSI) acquires a list for performance and use requirements for eyewash and shower equipment for emergency treatment of the eyes or body of a person exposed to hazardous materials.

The ANSI Z358.1 standard for emergency showers and eyewashes states that the equipment must be accessible within 10 seconds of a hazard.

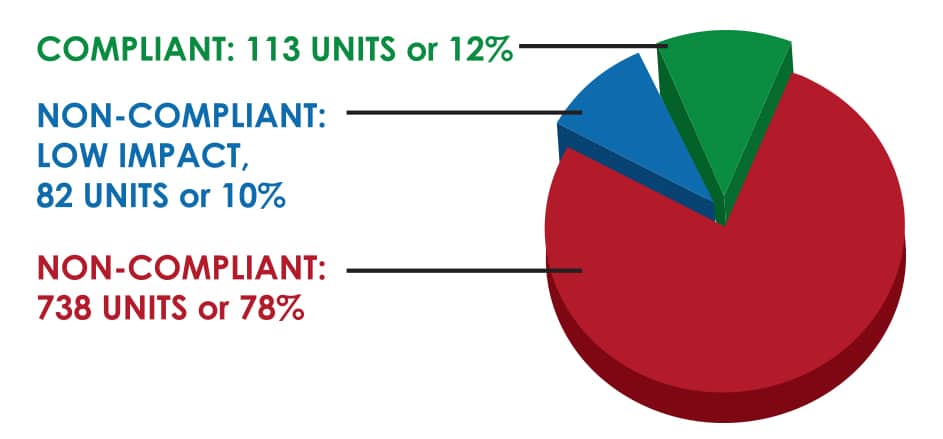

The figure to the left is based on a study of approximately 1,000 emergency showers and eye/face washes tested for compliance to the ANSI Z358.1-2014 Standard.

The figure to the left is based on a study of approximately 1,000 emergency showers and eye/face washes tested for compliance to the ANSI Z358.1-2014 Standard.

As you can see, it is quite common to find that the majority of emergency showers and eyewashes in the field are not compliant with the standard, potentially resulting in fines from OSHA, or worse, a site not being able to provide proper first aid in the event of an emergency. ANSI requires that all emergency showers and eyewashes are inspected on a weekly basis and a full test to be conducted annually, this is a crucial piece of the standard for maximum workplace safety.

Click here to obtain Haws‘ free ANSI Z358.1-2014 checklist. For more information on Haws‘ emergency showers and eyewashes, click here.

Repost: 2014 Emergency Eyewash, Shower Standard Revision RecapBy Roy Maurer, online editor/manager for Society for Human Resource Management

The national consensus standard for the selection, installation and maintenance of emergency eye, face and shower equipment was recently updated.

The International Safety Equipment Association (ISEA) received American National Standards Institute (ANSI) approval for ANSI/ISEA Z358.1-2014, American National Standard for Emergency Eyewash and Shower Equipment, and the update went into effect January 2015.

There is no grandfather clause, and existing equipment must be compliant with the revised standard.

“This globally accepted standard continues to be the authoritative document that specifies minimum performance criteria for flow rates, temperature and drenching patterns,” said Imants Stiebris, chairman of the ISEA Emergency Eyewash and Shower Group and safety products business leader at Speakman Co.

The Occupational Safety and Health Administration (OSHA) has a general requirement specifying where and when emergency eyewash and shower equipment must be available, but it does not specify operating or installation requirements.

That’s where the ANSI/ISEA standard comes in. While it doesn’t have the full force of an OSHA regulation, the standard helps employers meet OSHA requirements.

“Safety showers and eyewashes are your first line of defense should there be an accident,” said Casey Hayes, director of operations for Haws Integrated, a firm that designs, builds and manages custom-engineered industrial water safety systems. “We’ve seen OSHA stepping up enforcement of the standard in the last couple of years and issuing more citations,” he said.

What Is ANSI/ISEA Z358.1-2014?

The standard covers plumbed and self-contained emergency showers and emergency eyewash equipment, eye/face wash equipment, combination units, personal wash units and hand-held drench hoses. These systems are typically found in manufacturing facilities, construction sites, laboratories, medical offices and other workplaces.

The standard specifies minimum performance criteria for flow rates, temperature and drenching patterns for a user to adequately rinse off a contaminant in an emergency situation. It also provides maintenance directives to ensure that the equipment is in proper working condition.

One of the most significant requirements of the standard deals with the location of the equipment, Hayes said, and “It’s probably the most difficult part for employers to comply with.” The equipment must be accessible to workers within 10 seconds—a vague requirement, according to Hayes—but the standard’s appendix references 55 feet, he pointed out.

The wash or shower must be located on the same level as the hazard. “You can’t have somebody working on a stairwell and have to go up or down a flight to get to the shower. The equipment needs to be installed on the same level where the accident could happen,” he said.

The wash station must also be free of obstructions. “Someone needing to get to the shower or eyewash could be in a panic—their eyes could be blinded by chemicals—so employers must ensure that the shower is accessible and free of obstructions,” he said.

All equipment must be identified with highly visible signage, must be well-lit, and needs to be able to go from “off” to “on” in one second or less.

“The volume of water that is required for a 15-minute flow is not always considered,” Hayes said. The standard requires the victim to endure a flushing flow for a minimum of 15 minutes. With water pressure from the drench shower 10 times the amount of a typical residential shower, “that is a significant amount of water, and you need to deal with it on the floor and from a capacity standpoint,” he said.

The comfort of the person using the wash also needs to be considered. “It is not a pleasant experience to put your eyes in the path of water. The controlled flow of flushing fluid must be at a velocity low enough to be noninjurious to the user,” Hayes said.

The standard stipulates minimum flow rates of:

- 0.4 gallons per minute for eyewashes.

- 3 gallons per minute for eye/face washes. A good eye/face wash will have separate dedicated flows of water for your eyes and face, Hayes said.

- 20 gallons per minute for showers. That’s 300 gallons of water required for the 15-minute wash.

Washes must deliver tepid water defined as between 60 degrees and 100 degrees Fahrenheit.

Studies have shown that tepid water increases the chances that a victim can tolerate the required 15-minute wash. Tepid water also encourages the removal of contaminated clothing, which acts as a barrier to the flushing fluid.

“We’re also seeing employers putting showers in enclosed areas or in curtained areas, to promote the removal of clothing and alleviate workers’ privacy concerns,” Hayes said.

2014 Revisions to the Standard

There weren’t that many changes to the 2009 standard, but a few highlights include the following:

- A requirement was included that emergency showers be designed, manufactured and installed in such a way that, once activated, they can be operated without the use of hands.

- The way the height of eyewashes and eye/face washes are measured changed from the floor to the wash basin to from the floor to the water flow. The height should still be between 33 inches and 53 inches. “Something to consider when inspecting washes is to ensure that, even though your wash fits within these limits, it’s still realistically usable,” Hayes said.

- A single step up into an enclosure where the wash is accessed is not considered an obstruction. This had not been addressed previously.

The 2014 version further clarifies that fluid flow location and pattern delivery for emergency eyewashes and eye/face washes is the critical aspect in designing and installing these devices, rather than the positioning of nozzles. Additionally, illustrations have been updated to reflect contemporary design configurations.

Best Practices

Hayes recommended a few best practices that go above and beyond the standard and that he has seen used at companies with strong safety cultures:

- Locate washes and showers in areas with adequate space for emergency responders to fulfill their duties. “If the equipment is in a tight space, you’re preventing responders from helping victims,” he said. Enclosures can be built to allow multiple people to be inside.

- Monitor and evaluate all accessible components of washes and showers on a frequent and routine basis to manage potential problems.

- Use eye/face washes in lieu of simply eyewashes. “It’s highly unlikely that a chemical splash will only land on your eye surface. This is common sense, so put in the right equipment,” he said.

- Check that the washes meet the proper gauge height. The standard’s weekly activation requirement is mainly to ensure that water is available and to clear sediment buildup. “While a quick activation might seem sufficient, it’s not an accurate representation of functionality for the required 15-minute flush,” Hayes said. “If water is there but doesn’t rise up to the proper gauge height, you are compliant, but that equipment may fail you in the event that it’s needed.”

The ISEA’s new Emergency Eyewash and Shower Equipment Selection, Installation and Use Guide is a document that provides assistance on the proper selection, use and maintenance of equipment. The 22-page guide includes a frequently asked questions section and an annual inspection checklist.

The guide is available for download in PDF format.

[via SHRM]

Are You Compliant With the ANSI Z358.1-2014 Revisions?The American National Standards Institute (ANSI) introduced the ANSI Z358.1 – 2014 Standard for Emergency Eyewash and Shower Equipment update in January 2015.

If you missed our free webinar or would like to share the on-demand recording, see the link below:

In addition, below is a link to download the updated ANSI compliance checklist for testing your emergency showers and eyewashes.

Download the ANSI Z358.1 – 2014 Checklist (pdf) »