According to Occupational Health and Safety “The first 10-15 seconds after exposure to a hazardous substance, especially a corrosive substance, are critical. Delaying treatment, even for a few seconds, may cause serious injury. Emergency shower and eyewash stations provide on-the-spot decontamination. Emergency shower and eyewash stations are a necessary backup to minimize the effects of accident exposure to chemicals.”

The American National Standards Institute (ANSI) acquires a list for performance and use requirements for eyewash and shower equipment for emergency treatment of the eyes or body of a person exposed to hazardous materials.

The ANSI Z358.1 standard for emergency showers and eyewashes states that the equipment must be accessible within 10 seconds of a hazard.

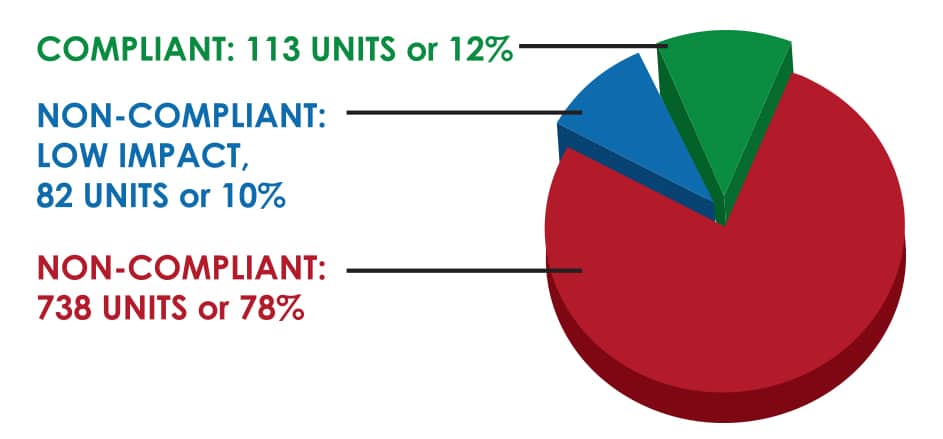

The figure to the left is based on a study of approximately 1,000 emergency showers and eye/face washes tested for compliance to the ANSI Z358.1-2014 Standard.

The figure to the left is based on a study of approximately 1,000 emergency showers and eye/face washes tested for compliance to the ANSI Z358.1-2014 Standard.

As you can see, it is quite common to find that the majority of emergency showers and eyewashes in the field are not compliant with the standard, potentially resulting in fines from OSHA, or worse, a site not being able to provide proper first aid in the event of an emergency. ANSI requires that all emergency showers and eyewashes are inspected on a weekly basis and a full test to be conducted annually, this is a crucial piece of the standard for maximum workplace safety.

Click here to obtain Haws‘ free ANSI Z358.1-2014 checklist. For more information on Haws‘ emergency showers and eyewashes, click here.