Specifications

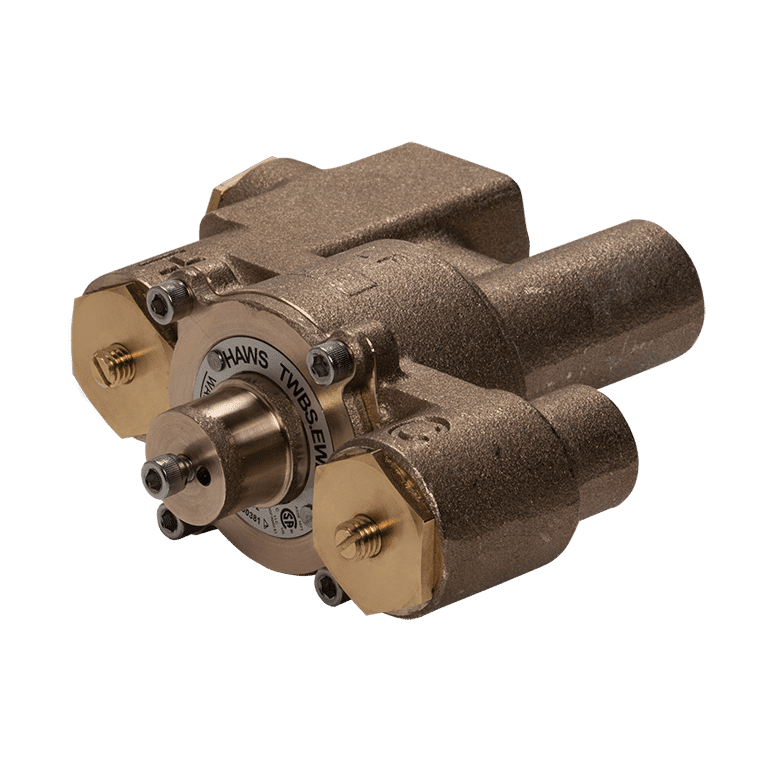

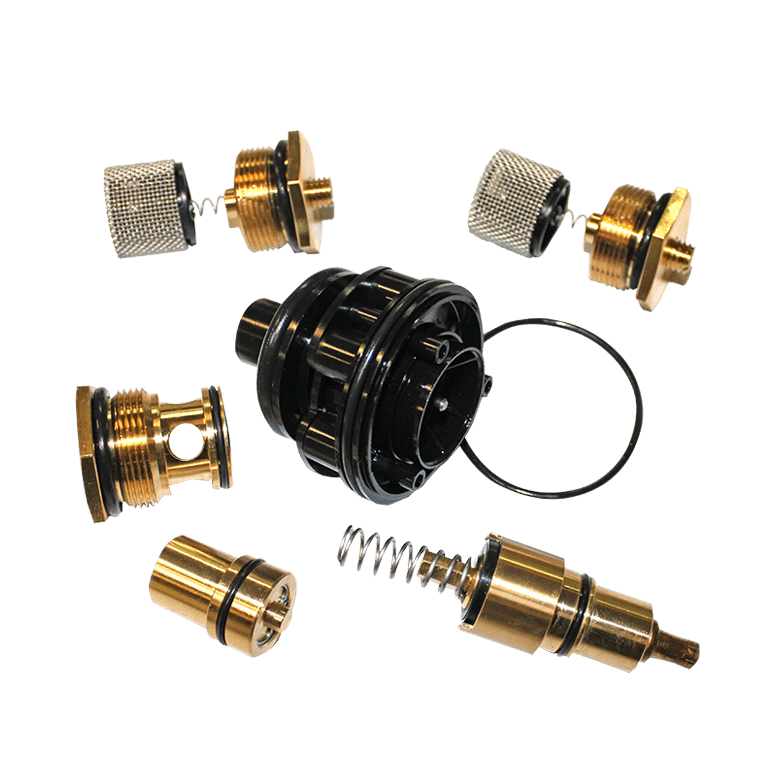

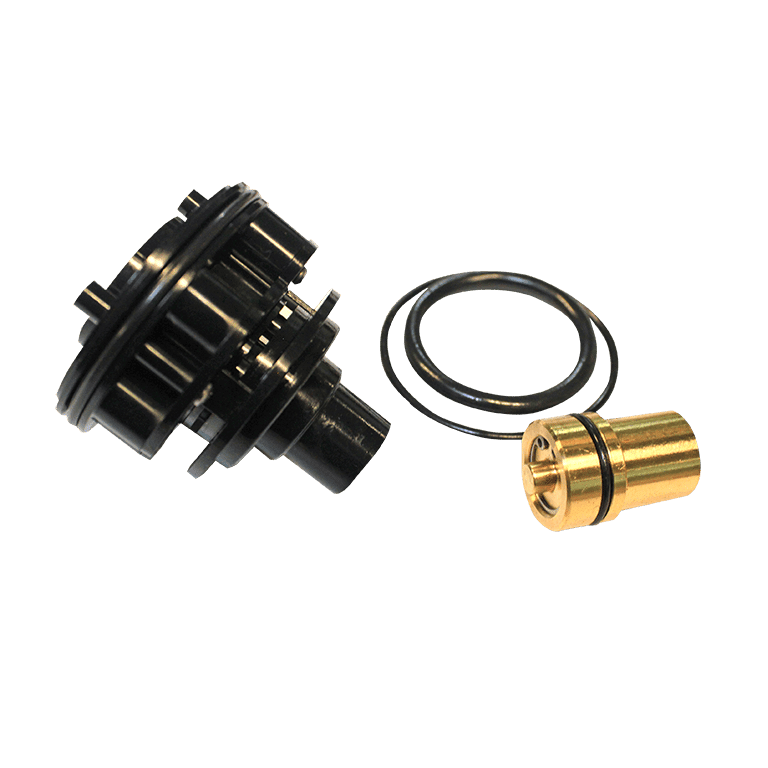

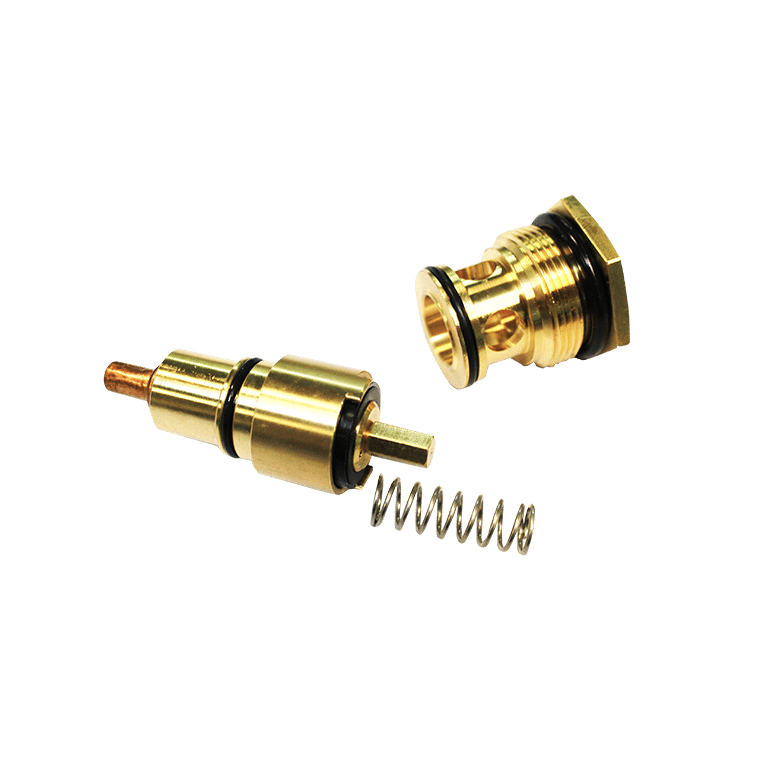

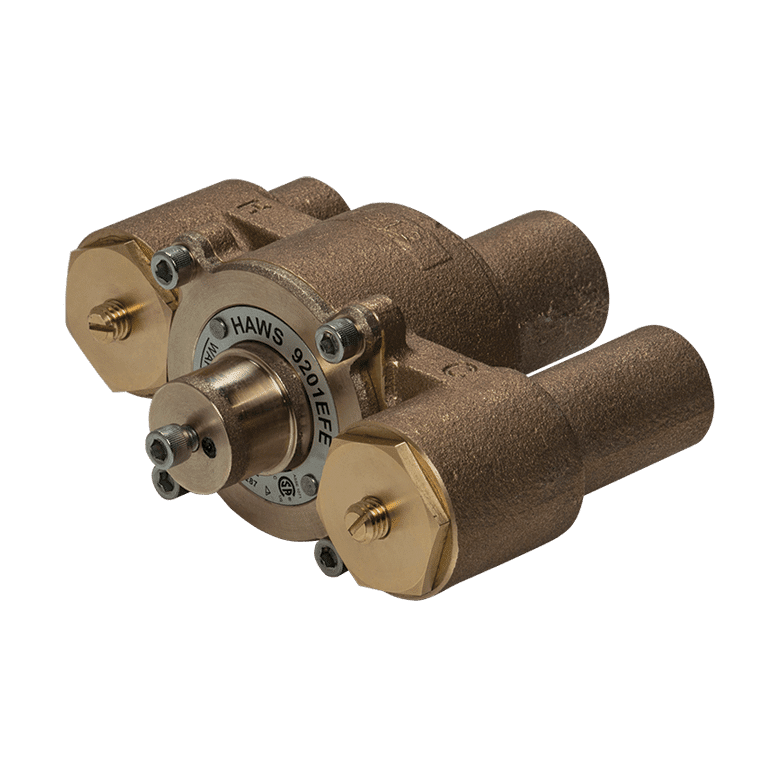

Model TWBS.EWE (patent pending) is a thermostatic mixing valve that mixes hot and cold water to supply tempered water to emergency eyewash fixtures requiring flow up to 12 gpm (45.4 L). Unit employs a paraffin filled thermostatic mixing element. Lowest internal pressure drop where supply pressure is low, and a high Cold Water Bypass flow rate of 10 gpm (37.8 L). The improved low-lead brass design with a one piece casting uses internal check stops, over-sized valve seats, a shuttle design that eliminates valve binding, and a funnel design to improve temperature control with better mixing at low flow rates. Lime and calcium resistant components are used throughout. The outlet temperature factory setting is 85° F (26° C). Maximum operating pressure: 125 psi (8.62 Bar). Temperature adjustment range 60 - 90° F (16 - 35° C). Maximum inlet temperature: 180° F (82° C). Recommended inlet temperature: 140° F (60° C). Minimum inlet temperature: 120° F (49° C) Inlet 1/2" NPT(F). Outlet 3/4" NPT(F).

Pricing Information

- $2852 USD

- Contact Haws Specials