Haws® exhibited at the recent International Facility Management Association (IFMA) World Workplace Conference & Expo October 18-20, 2017 in Houston, Texas. The World Workplace expo is an event geared toward learning and relationship-building within the facility management field. Attendees were able to see hundreds of Facility Management toys, tools, and resources from the leading names in FM solutions, including Haws. The attendees were able to see product demonstrations, attend informational sessions, and have one-on-ones with exhibitors. Haws was in a unique position to be the only Emergency Response Equipment and Hydration Products manufacturer at this event.

Haws AG also displayed at the A+A in Dusseldorf Germany. All aspects of safety, security, and health at work were brought together October 17-20, 2017 at the international trade forum that is A+A. Haws was able to present our emergency equipment and safety solutions to a global and highly qualified expert audience of decision-makers.

[via LabManager.com]

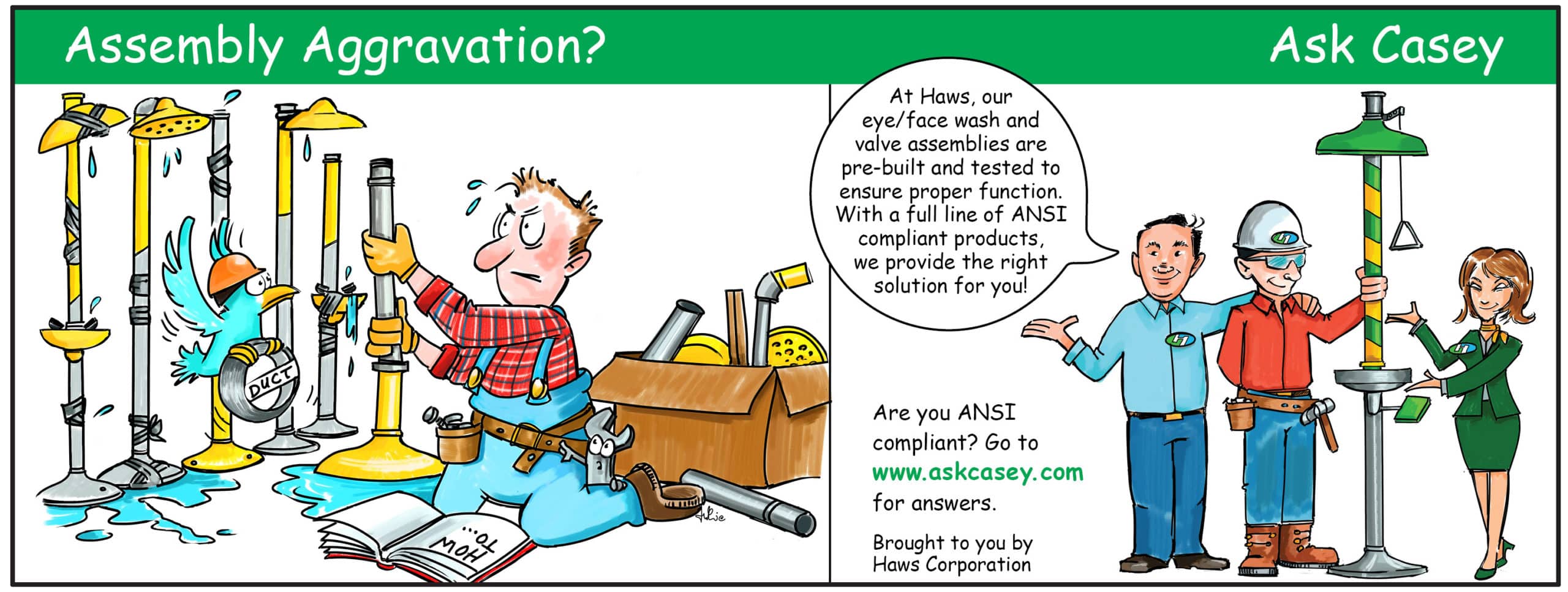

ANSI standard Z358.1 is detailed in terms of defining what is appropriate for safety showers and eyewash stations.

As lab managers and employees, we know that many inorganic chemicals (such as the mineral acids and alkalis) are corrosive to the skin and eyes. Likewise we are aware that many organic chemicals (such as acid halides, phenols, and so on) are corrosive and often toxic. Yet we Safety Guys are continually shocked by laissez-faire attitudes toward the use and maintenance of basic safety equipment by lab personnel, and the resultant unnecessary injuries.

One extreme example we constantly recall is the tragic UCLA accident just a few years ago, which resulted in a fatality from chemical burns.1 And we recently noticed a post on the American Industrial Hygiene Association pages for Lab Safety Chemical Exposure Incidents, where improper use of an eyewash resulted in a trip to the emergency room.2

The worker was using a fluorescent stain in the cytogenetics lab and felt something splash into his eyes. He was not wearing safety goggles or glasses. (D’oh!) Long story shortened, he flushed his eyes at the nearest eyewash, but they remained irritated and began to swell shut, necessitating a visit to the emergency room. Back at work a few days later, he noticed a coworker using the same eyewash to clean glassware and stainless steel trays, which were left resting in the sink in a cleaning solution. (What?!)

What does OSHA say?

In 29 CFR 1910.151 Medical Services and First Aid, it states that “where the eyes or body of any person may be exposed to injurious corrosive materials, suitable facilities for quick drenching or flushing of the eyes and body shall be provided within the work area for immediate emergency use.”3 OSHA doesn’t provide more specifics regarding what constitutes “suitable” or how “immediate” is defined. So how do we know if we are meeting the intent of the law?

Fortunately, we have the American National Standards Institute (ANSI), and their consensus standard Z358.1, last updated in 2014. This ANSI standard is very detailed in terms of defining what is appropriate for safety showers and eyewash stations. In fact, OSHA uses this reference as a guide when inspecting facilities. So let’s review what is “recommended” for acceptable safety equipment.

Safety shower specs

Begin by checking your facilities for the proper hardware, as recommended by Z358.1. Rest assured that OSHA will, should one or more agents show up for an inspection. For safety showers, the shower head must be capable of flowing 20 gallons per minute (gpm) at 30 psi and producing a 20-inch diameter spray pattern at 60 inches above the surface where the user stands. The center of the sprayhead pattern should be at least 16 inches from any wall, door, or obstruction. It is recommended that the shower head be mounted between 82 and 96 inches off the floor, with the valve no higher than 69 inches.

Eyewash specs

Eyewash stations target just the eyes and therefore have a lower flow requirement. ANSI Z358.1 recommends a flow of 0.4 gpm also at 30 psi. The nozzles should be at least six inches from any obstruction and mounted between 33 and 45 inches above the floor. An eyewash gauge should be used to verify and test the flow pattern.

Requirements for both

Both safety showers and eyewash stations must be able to provide the recommended flow for at least 15 minutes. This usually translates into having the equipment plumbed in with hard connections to the water supply. For example, a quick calculation for the safety shower at 20 gpm yields 300 gallons needed. Self-contained or personal wash devices are allowed, but they are considered supplemental units that can provide immediate flushing while transiting to the permanent fixture.

If the local climate presents potential for freezing conditions, the equipment must be designed to avoid freezing or protected against that situation. Activation valves must open within one second and remain open until intentionally closed or turned off. It goes without saying that these safety devices should be constructed of corrosion-resistant materials.

The 2014 update to Z358.1 added two important criteria. The first is that the requirement for tepid water is now defined as having a temperature of between 60 and 100 degrees Fahrenheit (15 to 37 degrees Celsius). The second change addresses simultaneous operation for combination units. This means that if you have a drench shower combined with an eyewash station, both devices must provide adequate flows and be fully operable at the same time.

Finally and most importantly, consider the location of equipment. We know you have the 10-second rule etched into your brain, as that is the most critical element when it comes to safety showers and eyewashes. This means that travel to the unit should be under 10 seconds for all hazardous areas that need this equipment. This equals about 55 feet. In addition, the drench shower or eyewash must be on the same level as the hazard and have a clear path for travel. We recommend painting or marking the floor area underneath the shower to help keep it clear. Z358.1 also recommends equipment be installed in a brightly lit area and marked with a highly visible safety sign.

Maintenance and training

The last thing you want is to rush to the eyewash or shower, only to be drenched with nasty, sediment-laden water. ANSI recommends flushing all equipment weekly to verify proper flow, and clearing the plumbing of any deposits. If your facility does not have floor drains installed, remember to bring a large, plastic trash can to catch the water. The weekly flushing can also provide a great training opportunity to refresh the operation and travel paths for your employees.

If you want to find out about the ANSI/ISEA Z358.1 significant requirements, attend our free 1-hour webinar on September 21st, 2017.

Register now and become subject matter experts of your emergency eyewash and shower equipment including weekly and annual testing. Request a certificate of attendance after the webinar.

This free webinar will cover:

• ANSI/ISEA Z358.1 significant requirements

• Important 2014 revision highlights

• Compliance best practices

• Live Q&A

WHAT: All You Need to Know About ANSI Z358.1 Webinar

WHEN: September 21, 2017 from 10am-11am PT / 1pm-2pm ET

PRESENTER: Justin Dunn, Product Specialist/Trainer and Samantha Hoch, Marketing Strategist

HOW: Register for free

Attendees will receive these complimentary materials after the webinar:

• OSHA white paper

• Weekly and Annual ANSI Checklist

• Access to On-Demand Webinar

References

1. “tert-Butyllithium Claims Fellow Chemist at UCLA,” Chemistry Blog, January 19, 2009, http://www.chemistry-blog.com/2009/01/20/tert-butyllithium-claims-fellow-chemist-at-ucla/.

2. “Lab Safety Chemical Exposures Incidents,” American Industrial Hygiene Association, https://www.aiha.org/get-involved/VolunteerGroups/LabHSCommittee/Incident%20Pages/Lab-Safety-Chemical-Exposures-Incidents.aspx.

3. “Medical Services and First Aid,” US Department of Labor, Occupational Health and Safety Administration, https://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=STANDARDS&p_id=9806.

Haws Receives Safety 2017 Attendee Choice Award

ISHN’s annual hands-on safety and health products and services awards – a complement to the Reader’s Choice Awards — are based on voting by attendees at the American Safety of Safety Engineers (ASSE) annual professional development conference.

Haws is proud to announce that our Tempered, Gravity-Fed, Portable Eyewash model 7501T is a winner in the category of Emergency Eyewashes at this year ASSE Safety 2017 conference Attendees Choice Award.

Model 7501T is a compact portable tempered eyewash and is ideal for remote locations. The 9-gallon (34 L), gravity-fed, eyewash uses a heated, insulated blanket to provide ANSI compliant tempered potable water in operating temperatures between -30° F (-34° C) and 100° F (38° C) for locations without access to a continuous potable water source. The self-contained heating blanket electrical system uses NEMA 3R rated components. 120V electrical requirement with supplied 8′ power cord.

- Featuring an FDA approved high-density green polyethylene tank easily activated by pulling the yellow activation arm down to the open position

- A wide-fill opening with threaded cap permits easy inspection, cleaning, and filling

- Relocation is simple due to the easily mounted bracket (included) and light design of this 9-gallon (34 L) portable

To see a complete line of Portable Eyewash solutions visit our website.

A Legacy of Innovation

By Stephanie Kilroy

One hundred and ten years ago, Luther Haws created a drinking solution that would become the first product for Haws Sanitary Drinking Faucet Company. Luther saw children drinking from a common cup on a playground at a public school; as a result, he invented a bubblerhead drinking faucet. This innovation sparked what would eventually be an enterprise business employing over two hundred employees globally.

The product innovation initiated by Luther Haws continued across generations. In the 1940’s, maintenance men from an oil refinery in Richmond, CA would come by the Haws plant in Berkeley to shop for parts: round ball type bubblers, flow regulator and fittings. After inquiring about the need for these spare parts instead of completed models, Haws was informed that these parts were being used to build equipment to flush eyes. Employees at Haws sought to understand the needs of the customer and began making these emergency eyewashes and drench showers for them. This was the unofficial launch of Haws emergency equipment products; the earliest drawings date back to 1949.

Haws employees have great pride in our innovative spirit which continues to thrive in 2017. One of Haws’ recent accomplishments has been the development of a professionalized R&D department. Under the leadership of Michael Joyer, new ideas are being generated regularly with many of these innovative ideas already introduced to the market. For example, the 7501T Tempered, Gravity-Fed, Portable Eyewash was one of the first products borne out of the R&D lab.

Haws employees have great pride in our innovative spirit which continues to thrive in 2017. One of Haws’ recent accomplishments has been the development of a professionalized R&D department. Under the leadership of Michael Joyer, new ideas are being generated regularly with many of these innovative ideas already introduced to the market. For example, the 7501T Tempered, Gravity-Fed, Portable Eyewash was one of the first products borne out of the R&D lab.

Haws is also called to innovate, not simply with new products, but in the way we do business. We are a stable, multigenerational family company, we are learning to change and improve processes. Haws employees are looking for internal efficiencies and ways in which we can best meet the needs of our customers. Recently, the Production team has developed a cross-training initiative aimed at flexing team work assignments to serve business demands.

These types of cross-functional, support teams are increasing and delivering impactful deliverables. In Q1, Marketing and Customer Service launched a Live Chat program on the Haws website to provide immediate access to customers. The Haws China website launch is another joint effort initiative intended to widen our global marketplace coverage. Launched in Q2 2017, this was a true collaboration between the Haws China and Corporate Marketing teams. And these are just a few of the examples of all the successful small and large activities that are helping drive change to redefine how we innovate, how we grow and how we foster a culture that is rewarding for all.

One hundred and ten years later, Haws continues our commitment to inventing, designing and manufacturing hydration products as well as standardized and customized emergency response products. With more than 8,000 distribution locations and 200 employees worldwide, we continually focus on quality, service, reliability and complete solution support. Headquartered in Sparks, Nevada, USA, Haws is globally represented with locations in Switzerland, Singapore, China, India, and Brazil. For more information on Haws, visit www.Hawsco.com.

Preparation: The Best Guard to an EmergencyDo you know the protocol to flushing hazardous chemicals off of your body in an emergency? It’s always a good rule of thumb to be knowledgeable on how to properly execute safety shower and eyewash performance in an emergency situation. Take the time to get to know the mechanics of the emergency equipment in your facility before an accident takes place. Casey Hayes, director of Haws Integrated™, recommends the following:

- Get a proper training session on emergency equipment. Be aware of the location of the unit and how long it takes to arrive at the unit from your work space.

- Confirm that it should not take more than 10 seconds to arrive to the emergency equipment.

- Upon arrival to the shower, pull lever and remain in shower for a full 15 minutes. This is to ensure the prevention of chemical absorption while it also helps to cool burns and prevent hypothermia.

- When using an eyewash or eye/face wash, hold eyes open during the entire 15 minute flushing period.

- In some cases, it may be appropriate to have a partner with you during the state of emergency. If you work alone, you may not have the opportunity to have someone assist you. We recommend that if you are in a state of shock, have a co-worker assist you to the emergency shower and or eyewash station. If you are saturated in chemicals, it is best not to expose anyone else and to proceed to the emergency station alone.

- Always go to the emergency room following the use of the emergency shower and/or eyewash.

Furthermore, it’s essential to have functional emergency showers and eyewashes throughout your facility. Refer to our previous blog post ANSI Z358.1 FAQ: What is the Weekly vs. Annual Test for a break down on when it is appropriate to perform each test. We also offer a free webinar on the requirements for emergency eyewashes and showers. Click here to watch.

Now Hiring: Senior Digital Marketing Specialist

Haws is hiring!

If you are interested in joining a forward thinking company that offers competitive wages, excellence benefits, a positive culture that allows the opportunity to learn and grow, and rewards for results, please apply.

We are looking to fill the position of Senior Digital Marketing Specialist.

If you or someone you know feels they are fit for this position, please apply. Click the link below to view the job description.

APPLY NOW

The Only Eyewash Video You Will Ever Need!

As you can tell we are pretty excited to introduce our brand, spanking new AXION® Videos.

And medical experts agree, AXION® MSR is a victim’s best choice for comfort, reliability and safety. Learn more in our new AXION MSR videos.

Advanced Safety Features of the Haws® Tankless Water Heater

By Casey Hayes, Director of Haws Integrated™

Tankless water heaters, also known as instantaneous water heaters, are designed to deliver a constant supply of hot water as needed without the use of a storage tank. When a water source is activated, cold water travels through a pipe, into the unit, and an electric element heats the water. Tempered water is a crucial component to victim comfort during emergency response. Not only does appropriately tempered water prevent hypothermia, enhanced victim comfort increases the user’s desire to stay in the shower for the full 15 minutes as prescribed by ANSI Z358.1.

To read the full white paper, click here.

AXION Advantage™: New Product of the Year2013 and 2014 have been great years as we launched various products including the Model 1900 Bottle Filler, the 9400 Steam Water Heat Exchanger, and the AXION Advantage™ System which have all received strong recognition within the industry. The AXION Advantage™ system offers health and safety professionals a medically superior response for upgrading existing emergency eyewash and shower equipment while exceeding ANSI compliance. With four Advantage kits providing the necessary pieces to convert 80% of existing eyewashes and showers, facilities will have the tools to upgrade older Haws® products, replace ineffective products and test for continued ANSI compliance.

Since it’s launch, AXION® MSR products new product has received numerous award for its ingenuity and ability. In fact, this new AXION Advantage™ System has recently received several occupational safety awards including the 2014 ISHN Readers’ Choice Award, the 2014 American Society of Safety Engineers – Safety Show’s Attendee Choice Award, the ISHN New Product of the Year Award, and the OH&S New Product of the Year Award. To learn about more of our innovative products, visit our Smart Innovation pages.

Look for Haws® on Autodesk®The Haws® team is excited to announce that we are now on Autodesk® Seek®. A program designed to provide detailed Revit® Files on our products, Autodesk® Seek® will help contractors, architects, and engineers gain valuable insight of how our products will fit into their projects. Autodesk® Seek® allows design professionals to search for specific product design files in the form of 3D models, 2D drawings, visual images, and part and product specification data. With more detailed project data, users are able to make better informed decisions throughout the project duration.

Users are able to work directly within the programs of AutoCAD and Revit®. The search engine is versatile with the ability to search for products by performance, equipment, sustainability, and dimensions. Visit our Autodesk® Seek® page and view our products here!