Haws® exhibited at the recent International Facility Management Association (IFMA) World Workplace Conference & Expo October 18-20, 2017 in Houston, Texas. The World Workplace expo is an event geared toward learning and relationship-building within the facility management field. Attendees were able to see hundreds of Facility Management toys, tools, and resources from the leading names in FM solutions, including Haws. The attendees were able to see product demonstrations, attend informational sessions, and have one-on-ones with exhibitors. Haws was in a unique position to be the only Emergency Response Equipment and Hydration Products manufacturer at this event.

Haws AG also displayed at the A+A in Dusseldorf Germany. All aspects of safety, security, and health at work were brought together October 17-20, 2017 at the international trade forum that is A+A. Haws was able to present our emergency equipment and safety solutions to a global and highly qualified expert audience of decision-makers.

Haws® is proud to introduce the new Performance Series Overhead Tank Shower to our extensive line of emergency response tempering solutions by Haws Integrated®. Model 8740 is a pre-engineered and self-contained overhead tank shower designed for indoor and non-extreme outdoor climate installations. Starting with a standard base model, the 8740 allows for many enhanced options to meet customers’ needs.

The compact height and modular frame design allows for placement in areas not normally considered for shower installations or in areas where there is no or insufficient water supply. This model is ideal for projects where mobility, fast delivery, and low-cost solutions are needed. The unit is ANSI/ISEA Z358.1-2014 and EN 15154 compliant as a stand-alone unit at 60- 100°F (16-38°C) ambient temperature.

Some of the enhanced options include AXION® MSR Eye/Face Wash, Fiberglass Privacy Panels, Tank Temperature Gauge, Scald and Freeze Valves, Light and Alarm, Immersion Heaters, Auto-Fill Valve, Level Indicator, Proximity Switches, and Chillers.

To learn more:

- watch the short 8740 Product Overview Video

- download the 8740 Product Flyer

Spec sheets and supplemental information for this model and all options is available to download on the Hawsco.com website.

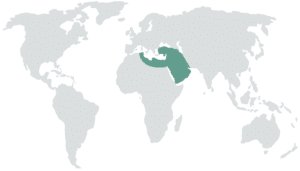

Haws Corporation expands access in Middle East

Haws – Switzerland announced its expansion into new markets in the Middle East, increasing its investment and presence to come closer to partners in key markets. This new extension will provide immediate access for customers in the region to help Haws better serve their needs and to develop stronger partnerships with local entities.

Haws – Switzerland announced its expansion into new markets in the Middle East, increasing its investment and presence to come closer to partners in key markets. This new extension will provide immediate access for customers in the region to help Haws better serve their needs and to develop stronger partnerships with local entities.

Recently, Haws welcomed two regional sales team members, Sampeep Verma and Michael Alex, as Business Development Managers – Middle East. Mr. Verma and Mr. Alex split territory coverage with specific regions assigned.

“Over the last 30 years, we have made tremendous progress in establishing Haws as a significant player in the EMEA safety equipment marketplace and expanding our reach to local markets. As one of the fastest growing markets globally, Middle East is an important and strategic region to continue our growth plans,” said Urs Weder, Manager Director of Haws – AG.

The Haws team will be showcasing new products and services at the A+A International Trade Fair and Congress in Dusseldorf in October in Hall 7A at Booth F13.

For more information, visit www.Haws.ch or [email protected].

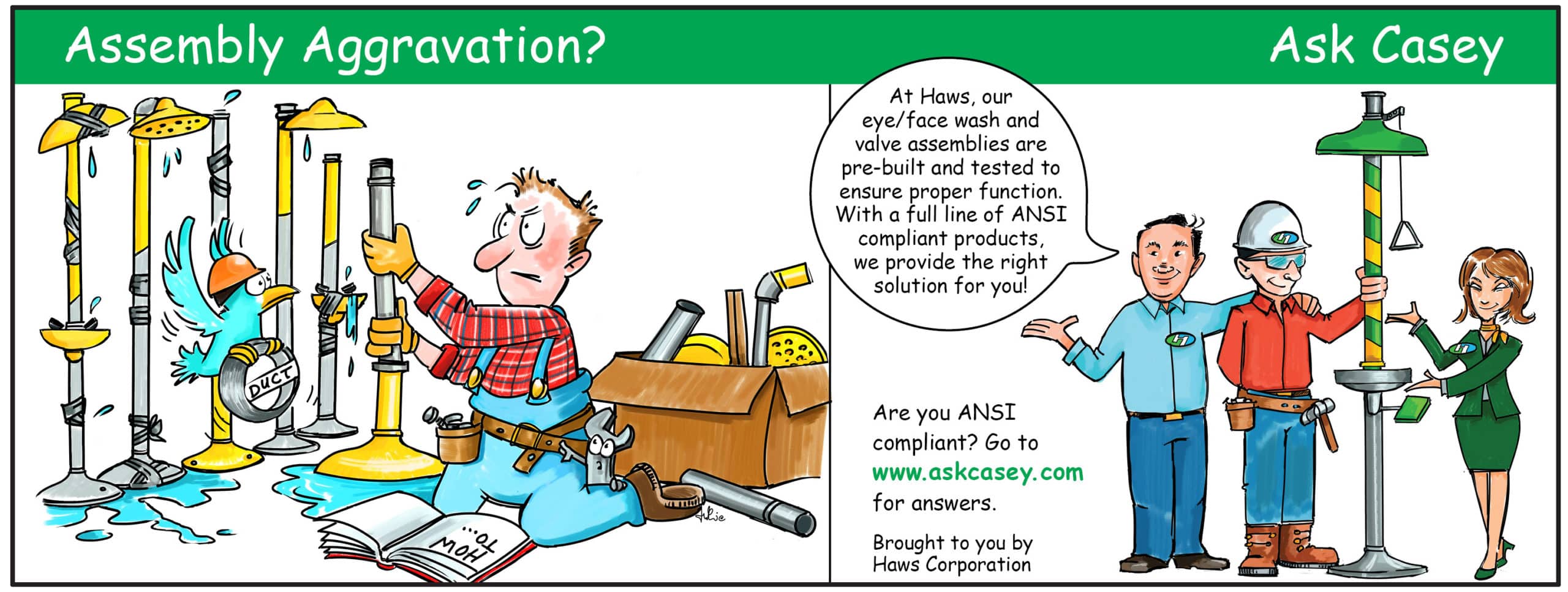

ANSI Z358.1 FAQ’S: eyewash or eye/face wash? OSHA or ANSI?Casey Hayes, Director of Haws Integrated™, is our go-to expert for questions on ANSI Z358.1. For your quick reference, Casey has responded to your most frequently asked questions to help you stay up-to-date on ANSI compliance.

What is the difference between an eye/face wash and just an eyewash?

An eyewash is specific to eyes, and the water flow rate is designed to hit only the eye surface. It is imperative that the eyewash temperature be 60° – 100° F and have a continuous flow for a full fifteen minutes. Having an eyewash with the right requirements will not only make a difference between temporary blindness and permanent blindness, but increase productivity. Nearly 2,000 eye injuries occur each day in the workplace and with only half of U.S. workplaces in compliance, the cost of an injury can be significant.

An eye/face wash will cover the eyes and a portion of the face. In addition, an eyewash has a .4 gpm minimum flow rate and an eye/face wash has a 3.0 gpm minimum flow rate.

Eye/face washes are beneficial because it’s rare that a victim only has a chemical hit the eye area so using an eye/face wash to flush more of the exposed area will only increase and enhance the emergency response.

Does OSHA use the ANSI standard?

OSHA requires the employer to provide suitable facilities for quick drenching or flushing of the eyes. While OSHA has not formally adopted ANSI Z358.1, they refer employers to the standard as a source of guidance. In other words, OSHA agrees to enforce safety standards presented by ANSI, while ANSI acts as an assistant to OSHA with safety and health standards. ANSI is recognized as an approval agency of voluntary national consensus standards.

It is the employer’s responsibility to assess the particular conditions related to the needs of the site to ensure the eye/face wash and shower unit(s) provide suitable protection for employees.

For more questions regarding ANSI Z358.1, read our white paper here.

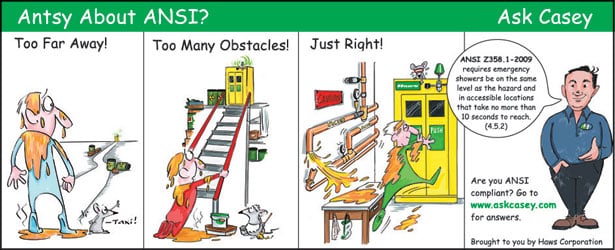

Safety Tip: Equipment Location Installation – Defining ObstructionsIf it only takes a single hop, skip, or jump to get to a piece of emergency equipment from any location in your workplace, your workplace is in compliance with one of the ANSI Z358.1 requirements. A walk to the nearest emergency equipment location should total less than 10 seconds and be obstruction free. But what defines obstruction?

Our definition of obstruction is not limited to obstacles or barriers (pipes, closed doors), it also includes impediments or delays (stairs, curbs). An obstruction would be anything that impedes access to the equipment by increasing the time to reach the unit or causing further injury. There are obvious obstructions that would clearly delay access to an emergency response shower unit in 10 seconds or less but other hazards could not only cause a delay but could cause further injury. Stairs (because of the requirement to be on the same level as the hazard), piping, boxes, cabinets, trash, office furniture, etc would all be considered a clear obstruction and should be cleared from the equipment area.

Doors are specifically discussed in the appendix of the standard which is not part of the standard but serves as a guide. The standard states that if a door is used, it must open in the direction towards the shower. Yet, a typical door that opens with a handle would not be accepted per the appendix. Ideally a shower unit that is enclosed will have saloon-type doors that swing in and out for access and don’t require the added motion and added time of twisting a handle. If a door is needed for privacy or temperature control, it must open in the direction of the shower without any type of handle to open the door.

Considerations for equipment location should go into effect before purchasing and installing. It’s important to keep in mind where each individual piece will be stationed and how many pieces will need to be purchased to make sure you are creating a predictable, reliable, stable environment to reduce any unnecessary emergency response problems or delays.

To stay up-to-date on additional safety tips, watch the ”Haws Presents ANSI Z358.1 Answered” on-demand webinar by clicking here.

Preparation: The Best Guard to an EmergencyDo you know the protocol to flushing hazardous chemicals off of your body in an emergency? It’s always a good rule of thumb to be knowledgeable on how to properly execute safety shower and eyewash performance in an emergency situation. Take the time to get to know the mechanics of the emergency equipment in your facility before an accident takes place. Casey Hayes, director of Haws Integrated™, recommends the following:

- Get a proper training session on emergency equipment. Be aware of the location of the unit and how long it takes to arrive at the unit from your work space.

- Confirm that it should not take more than 10 seconds to arrive to the emergency equipment.

- Upon arrival to the shower, pull lever and remain in shower for a full 15 minutes. This is to ensure the prevention of chemical absorption while it also helps to cool burns and prevent hypothermia.

- When using an eyewash or eye/face wash, hold eyes open during the entire 15 minute flushing period.

- In some cases, it may be appropriate to have a partner with you during the state of emergency. If you work alone, you may not have the opportunity to have someone assist you. We recommend that if you are in a state of shock, have a co-worker assist you to the emergency shower and or eyewash station. If you are saturated in chemicals, it is best not to expose anyone else and to proceed to the emergency station alone.

- Always go to the emergency room following the use of the emergency shower and/or eyewash.

Furthermore, it’s essential to have functional emergency showers and eyewashes throughout your facility. Refer to our previous blog post ANSI Z358.1 FAQ: What is the Weekly vs. Annual Test for a break down on when it is appropriate to perform each test. We also offer a free webinar on the requirements for emergency eyewashes and showers. Click here to watch.

How To Protect Your Workers From Hypothermia

EMERGENCY RESPONSE BEST PRACTICES :: PROTECTION AGAINST HYPOTHERMIA

Low ambient temperature and wind chill may simply be part of the job in cold climates, but they can have a lethal effect on exposed skin – particularly when combined with hazardous conditions where safety showers are required. This problematic combination creates a scenario for an ineffective and injurious emergency shower response. In some cases, inappropriate safety equipment can actually speed up the potential for cold-temperature related injuries like hypothermia. To ensure everyone’s safety, awareness and adherence to proper procedures and safety standards is critical.

UNDERSTANDING COLD-TEMP RELATED INJURY RISKS

Occupational Safety & Health Administration (OSHA) defines hypothermia as a cold-temp related injury in which normal body temperature drops to or below 95°F/35°C. Symptoms include drowsiness or fatigue, bluish skin, uncontrollable shivering, slurred speech and clumsy movements. Permanent tissue damage and death can result if hypothermia is left untreated.

EXPOSED FLESH in 0°F/17.8°C with 10mph wind

speed is in danger of hypothermia within 1-minute

Specific conditions in cold-weather climates can increase the risk of cold-temp related injuries, including hypothermia, which can affect a person even when land temperatures are above freezing or water temperatures are below 98.6oF/37oC. Factors influencing these injuries include:

• Low ambient temperatures and/or wind chill

• Wet skin, which freezes at a higher temperature than dry skin

• Exposed skin

While the ANSI Z358.1 Standard outlines suitable water temperatures as tepid – with a defined range of 60 to 100°F/15.5 to 37.77°C – and requires a full 15-minute drench period, the low end of this accepted temperature range can exacerbate the effects of hypothermia, particularly when exposure lasts the entire drench period. In addition, ANSI Z358.1 Appendix B6 states: Colder ambient temperatures might require an enclosure for added protection – even with water supplied in the ANSI Z358.1 specified temperature range, there is a high risk of hypothermia for wet victims exposed

to frigid ambient temperatures where loss of body heat is intensified by the effects of evaporative cooling and wind chill. It is crucial that the proper safety shower system is provided to prevent an incident where hypothermia could intensify an injury to a victim already in a hazardous situation.

SAFETY SOLUTIONS FOR COLD-WEATHER CLIMATES

Haws Integrated™ offers a variety of customized, ANSI compliant enclosed safety solutions for all climates. Features specific to equipment intended for use in cold-weather climates include combination units enclosed in booths with all-weather insulation, water-proof exterior coating, self-closing shower doors, built-in heaters, internal hot water supply and medically superior, non-injurious water flow, all of which qualify as industry best practices. Enclosures eliminate frigid environments by providing a shower area at a safe ambient temperature, out of the elements. Properly preparing a site for the use of climate specific equipment can mean the difference in minimizing or increasing the severe effects of cold-temperature injuries.

For more information, visit HawsIntegrated.com.

Last chance to register: Free ANSI Web SeminarYour Guide to ANSI Z358.1 Compliance

DATE: JUNE 23rd, 2016

TIME: 10:00-11:00am PT/ 1:00-2:00pm ET

DESCRIPTION: In November 2015, it was signed into law that OSHA fines are increasing by 80% for the first time since 1990. Ensure you are  compliant with the updated ANSI Z358.1 Standard to avoid fines and guarantee you are providing properly functioning emergency equipment.

compliant with the updated ANSI Z358.1 Standard to avoid fines and guarantee you are providing properly functioning emergency equipment.

Hosted by leading ANSI compliance field expert Casey Hayes, this free web seminar will cover:

• ANSI Z358.1-2014 revisions and significant requirements

• Compliance best practices

• Live Q&A

Attendees will receive:

• Complimentary OSHA white paper

• ANSI checklist

• Access to on-demand webinar

Your Guide to ANSI Z358.1 Compliance

DATE: JUNE 23rd, 2016

TIME: 10:00-11:00am PT/ 1:00-2:00pm ET

DESCRIPTION: In November 2015, it was signed into law that OSHA fines are increasing by 80% for the first time since 1990. Ensure you are  complaint with the updated ANSI Z358.1 Standard to avoid fines and guarantee you are providing properly functioning emergency equipment.

complaint with the updated ANSI Z358.1 Standard to avoid fines and guarantee you are providing properly functioning emergency equipment.

Hosted by leading ANSI compliance field expert Casey Hayes, this free web seminar will cover:

• ANSI Z358.1-2014 revisions and significant requirements

• Compliance best practices

• Live Q&A

Attendees will receive:

• Complimentary OSHA white paper

• ANSI checklist

• Access to on-demand webinar

You are aware that you need to provide tepid/tempered flushing fluid to your emergency showers and eyewashes in order to comply with the ANSI Z358.1 Standard requirement of 60-100°F for a full 15 minutes, but how you ask?

In this short video, we discuss just one of many ways to temper the flushing fluid of an emergency fixture: Thermostatic Mixing Valves. Haws offers multiple models to suit your needs, from a single eyewash to a full tempered booth package, Haws has the valve for you.

Please visit HawsIntegrated.com for more information or click here to contact Haws Integrated about your project.

For other ways to temper such as by steam, click here.

Readying Emergency Equipment For The Cold

With winter officially upon us, freezing temperatures can be expected across many parts of the country. In some areas, exceptionally cold weather will linger indefinitely, while other regions will experience freeze-thaw cycles. If you haven’t already done so, take the time now to ensure that your emergency equipment is ready for the cold weather, no matter how long it’s expected to last.

In the event of an accident, frozen safety equipment that cannot be operated properly, or at all, will turn an emergency into a disaster. It’s precisely this scenario that drives many plant safety managers to inspect and re-inspect their respective emergency equipment environments all the more diligently at this time of year – as well they should. While the best approach to ensuring that safety equipment is always in prime operating condition is with proper product installation, preventative maintenance and routine inspection and testing, there are other methods that are often taken to remedy emergency equipment prone to freezing.

If you live and work in a part of a country in which it’s common to have long periods of time with the temperature staying firmly below freezing, consider these approaches to keeping your emergency equipment operating properly.

The Bury Valve

This approach has been used for years. It involves burying the actuation valve for the equipment beneath the frost line in the ground. A mechanical linkage connects the buried valve to a mechanical paddle or other method of point-of-use actuation. Also incorporated into this design is a pressure valve, which is located below the frost line as well, that releases all water above the pressure valve when it is not actuated. With this design configuration, all water is left below the frost line until it is needed and remaining water is drained to the ground below the frost line once the equipment is turned off. It is appropriate to test the bury valve, linkage and the pressure valve prior to the onset of winter. If the pressure valve is inoperative – allowing water to stand above the frost line – it may not be noticeable until it’s already too late.

Electric Heat-Traced Tape

A popular technology set these days involves the use of electric heat-traced tape wrapped around the pipes and emergency equipment componentry above the frost line. With this alternative, water is available instantaneously, as it is resident in the equipment at all times. While we’ve seen many examples of plants in which standard emergency equipment was modified by the use of heat-traced tape in an effort to make it freeze-proof, it’s not always a recommended approach. The electric heat-traced tape systems use matched components specifically designed for that purpose, but the issue here is that you may have no idea that there’s a freeze problem until someone in dire need tries to use the equipment! Another method that can backfire extraordinarily involves “shade-tree” installations. In this set-up, steam pipes are run close to emergency equipment or emergency equipment supply pipes in an effort to prevent freezing. This presents two potential complications. Hot spots, or scalding hot water at the point of use, or freezing in areas not quite close enough to the warmth, both have the potential to create hidden problems – hidden, that is, until you use the equipment.

All of that said, heat-traced tape emergency equipment systems remain the most cost-effective answer in areas that experience significant below freezing periods. And in fact, the same heat-tracing technology that makes this approach effective (even if wrapping standard equipment with tape can mask potential problems) can be found on safety equipment that was designed specifically to withstand severe temperatures. The AXION® MSR Freeze-Protected Shower and Eye/Face Wash has safety features including insulation surrounding all piping and an outside jacket designed to prevent freezing. It will operate in temperatures as low as -30°F (-34.4°C). A system such as this effectively eliminates the need for modifications in the colder months – with proper maintenance, it will perform as well in the winter as it does in the summer. An all-weather model like Outdoor Tempered Shower and Eye/Face System is another option. This standard decontamination booth supplies tempered water to the heated shower and eye/face wash no matter how cold it gets outside.

What about parts of the country where prolonged periods of freezing are unlikely, but the occasional snap freeze is a likelihood? In that case, there is a range of anti-freeze valves available to suit varying equipment. These valves, each using a variety of different technologies, turn on a trickle of water during a snap freeze to minimize the possibility of freezing. For example, the Freeze Protection Bleed Valve is a fully engineered freeze-protection valve constructed of a single piece of brass. The automatic thermal actuator bleed valve opens when water temperatures drop below 35°F (1.7°C). It closes completely when the water temperature is above 42°F (5.6°C).

Products in this category are clearly aimed at snap-freeze environments only, due to both water waste with prolonged use and the possibility of pooling and then freezing in many applications. While there is no way of knowing what winter has in store this or any year, failure to prepare can mean significant problems in the event of an emergency. Maintain routine inspections and testing on your safety equipment, and consider alternatives that will ensure your plant’s ability to withstand freeze temperatures – just in case. As with many things, better safe than sorry.

More information on our full range of freeze-resistant equipment.

Download our white paper here>>

Web Seminar Invitation: ANSI Z358.1 Compliance Guide

Web Seminar Invitation:

ANSI Z358.1 Compliance Guide

PRESENTER: Casey Hayes, Director of Haws Integrated™ Operations

DATE: Thursday, February 18th

TIME: 10am-11am PT/1pm-2pm ET

Take advantage now by registering.

In November 2015, it was signed into law that OSHA fines are increasing by 80% for the first time since 1990. Ensure you are complaint with the updated ANSI Z358.1 Standard to avoid fines and guarantee you are providing properly functioning emergency equipment.

Hosted by leading ANSI compliance field expert Casey Hayes, this FREE web seminar will cover:

• ANSI Z358.1-2014 revisions and significant requirements

• Compliance best practices

• Live Q and A

Attendees will receive:

• Complimentary OSHA white paper

• ANSI checklist

• Access to on-demand webinar

About Haws IntegratedTM

Haws IntegratedTM designs, builds, and manages custom-engineered industrial safety systems that provide tempered water when and where it is needed.