[via LabManager.com]

ANSI standard Z358.1 is detailed in terms of defining what is appropriate for safety showers and eyewash stations.

As lab managers and employees, we know that many inorganic chemicals (such as the mineral acids and alkalis) are corrosive to the skin and eyes. Likewise we are aware that many organic chemicals (such as acid halides, phenols, and so on) are corrosive and often toxic. Yet we Safety Guys are continually shocked by laissez-faire attitudes toward the use and maintenance of basic safety equipment by lab personnel, and the resultant unnecessary injuries.

One extreme example we constantly recall is the tragic UCLA accident just a few years ago, which resulted in a fatality from chemical burns.1 And we recently noticed a post on the American Industrial Hygiene Association pages for Lab Safety Chemical Exposure Incidents, where improper use of an eyewash resulted in a trip to the emergency room.2

The worker was using a fluorescent stain in the cytogenetics lab and felt something splash into his eyes. He was not wearing safety goggles or glasses. (D’oh!) Long story shortened, he flushed his eyes at the nearest eyewash, but they remained irritated and began to swell shut, necessitating a visit to the emergency room. Back at work a few days later, he noticed a coworker using the same eyewash to clean glassware and stainless steel trays, which were left resting in the sink in a cleaning solution. (What?!)

What does OSHA say?

In 29 CFR 1910.151 Medical Services and First Aid, it states that “where the eyes or body of any person may be exposed to injurious corrosive materials, suitable facilities for quick drenching or flushing of the eyes and body shall be provided within the work area for immediate emergency use.”3 OSHA doesn’t provide more specifics regarding what constitutes “suitable” or how “immediate” is defined. So how do we know if we are meeting the intent of the law?

Fortunately, we have the American National Standards Institute (ANSI), and their consensus standard Z358.1, last updated in 2014. This ANSI standard is very detailed in terms of defining what is appropriate for safety showers and eyewash stations. In fact, OSHA uses this reference as a guide when inspecting facilities. So let’s review what is “recommended” for acceptable safety equipment.

Safety shower specs

Begin by checking your facilities for the proper hardware, as recommended by Z358.1. Rest assured that OSHA will, should one or more agents show up for an inspection. For safety showers, the shower head must be capable of flowing 20 gallons per minute (gpm) at 30 psi and producing a 20-inch diameter spray pattern at 60 inches above the surface where the user stands. The center of the sprayhead pattern should be at least 16 inches from any wall, door, or obstruction. It is recommended that the shower head be mounted between 82 and 96 inches off the floor, with the valve no higher than 69 inches.

Eyewash specs

Eyewash stations target just the eyes and therefore have a lower flow requirement. ANSI Z358.1 recommends a flow of 0.4 gpm also at 30 psi. The nozzles should be at least six inches from any obstruction and mounted between 33 and 45 inches above the floor. An eyewash gauge should be used to verify and test the flow pattern.

Requirements for both

Both safety showers and eyewash stations must be able to provide the recommended flow for at least 15 minutes. This usually translates into having the equipment plumbed in with hard connections to the water supply. For example, a quick calculation for the safety shower at 20 gpm yields 300 gallons needed. Self-contained or personal wash devices are allowed, but they are considered supplemental units that can provide immediate flushing while transiting to the permanent fixture.

If the local climate presents potential for freezing conditions, the equipment must be designed to avoid freezing or protected against that situation. Activation valves must open within one second and remain open until intentionally closed or turned off. It goes without saying that these safety devices should be constructed of corrosion-resistant materials.

The 2014 update to Z358.1 added two important criteria. The first is that the requirement for tepid water is now defined as having a temperature of between 60 and 100 degrees Fahrenheit (15 to 37 degrees Celsius). The second change addresses simultaneous operation for combination units. This means that if you have a drench shower combined with an eyewash station, both devices must provide adequate flows and be fully operable at the same time.

Finally and most importantly, consider the location of equipment. We know you have the 10-second rule etched into your brain, as that is the most critical element when it comes to safety showers and eyewashes. This means that travel to the unit should be under 10 seconds for all hazardous areas that need this equipment. This equals about 55 feet. In addition, the drench shower or eyewash must be on the same level as the hazard and have a clear path for travel. We recommend painting or marking the floor area underneath the shower to help keep it clear. Z358.1 also recommends equipment be installed in a brightly lit area and marked with a highly visible safety sign.

Maintenance and training

The last thing you want is to rush to the eyewash or shower, only to be drenched with nasty, sediment-laden water. ANSI recommends flushing all equipment weekly to verify proper flow, and clearing the plumbing of any deposits. If your facility does not have floor drains installed, remember to bring a large, plastic trash can to catch the water. The weekly flushing can also provide a great training opportunity to refresh the operation and travel paths for your employees.

If you want to find out about the ANSI/ISEA Z358.1 significant requirements, attend our free 1-hour webinar on September 21st, 2017.

Register now and become subject matter experts of your emergency eyewash and shower equipment including weekly and annual testing. Request a certificate of attendance after the webinar.

This free webinar will cover:

• ANSI/ISEA Z358.1 significant requirements

• Important 2014 revision highlights

• Compliance best practices

• Live Q&A

WHAT: All You Need to Know About ANSI Z358.1 Webinar

WHEN: September 21, 2017 from 10am-11am PT / 1pm-2pm ET

PRESENTER: Justin Dunn, Product Specialist/Trainer and Samantha Hoch, Marketing Strategist

HOW: Register for free

Attendees will receive these complimentary materials after the webinar:

• OSHA white paper

• Weekly and Annual ANSI Checklist

• Access to On-Demand Webinar

References

1. “tert-Butyllithium Claims Fellow Chemist at UCLA,” Chemistry Blog, January 19, 2009, http://www.chemistry-blog.com/2009/01/20/tert-butyllithium-claims-fellow-chemist-at-ucla/.

2. “Lab Safety Chemical Exposures Incidents,” American Industrial Hygiene Association, https://www.aiha.org/get-involved/VolunteerGroups/LabHSCommittee/Incident%20Pages/Lab-Safety-Chemical-Exposures-Incidents.aspx.

3. “Medical Services and First Aid,” US Department of Labor, Occupational Health and Safety Administration, https://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=STANDARDS&p_id=9806.

Last chance to register: Free Emergency Equipment WebinarWebinar Invitation:

YOUR GUIDE TO CHOOSING

THE PROPER EMERGENCY EQUIPMENT

PRESENTER: Dennis O’Neill, Haws Safety Education Specialist

PRESENTER: Dennis O’Neill, Haws Safety Education Specialist

Preparation: The Best Guard to an Emergency

Do you know the protocol to flushing hazardous chemicals off of your body in an emergency? It’s always a good rule of thumb to be knowledgeable on how to properly execute safety shower and eyewash performance in an emergency situation. Take the time to get to know the mechanics of the emergency equipment in your facility before an accident takes place. Casey Hayes, director of Haws Integrated™, recommends the following:

- Get a proper training session on emergency equipment. Be aware of the location of the unit and how long it takes to arrive at the unit from your work space.

- Confirm that it should not take more than 10 seconds to arrive to the emergency equipment.

- Upon arrival to the shower, pull lever and remain in shower for a full 15 minutes. This is to ensure the prevention of chemical absorption while it also helps to cool burns and prevent hypothermia.

- When using an eyewash or eye/face wash, hold eyes open during the entire 15 minute flushing period.

- In some cases, it may be appropriate to have a partner with you during the state of emergency. If you work alone, you may not have the opportunity to have someone assist you. We recommend that if you are in a state of shock, have a co-worker assist you to the emergency shower and or eyewash station. If you are saturated in chemicals, it is best not to expose anyone else and to proceed to the emergency station alone.

- Always go to the emergency room following the use of the emergency shower and/or eyewash.

Furthermore, it’s essential to have functional emergency showers and eyewashes throughout your facility. Refer to our previous blog post ANSI Z358.1 FAQ: What is the Weekly vs. Annual Test for a break down on when it is appropriate to perform each test. We also offer a free webinar on the requirements for emergency eyewashes and showers. Click here to watch.

FAQ’s on the AXION eyePOD Faucet-Mounted Eyewash

AXION® eyePOD®- An AXION Eyewash Everywhere

The AXION eyePOD offers a thermostatically-controlled, faucet-mounted eyewash that provides facilities with AXION Medically Superior Response eyewash capabilities in an attractive, low profile, cost efficient design.

How does it work?

Using the eyePOD is easy. Simply activate your faucet and rotate the front of the eyePOD one-half turn, either direction, to point the eyewash spouts upward. Water is discharged from the two eyewash ports for a soothing eye-cleansing experience. Once completed, rotate the eyePOD back to its standard position, with the logo facing upward, and water will flow naturally through your faucet.

When is a faucet-mounted eyewash needed?

The need for any eyewash depends on the level of workplace hazards. If there is a risk of splash, irritant or debris into the eyes, then most regulatory bodies mandate an ANSI Z358.1 Standard compliant eyewash with a 1-second activation. A faucet-mounted unit offers economical advantages, ease of use, and location convenience.

Where should it be located?

According to the ANSI Z358.1 Standard, it is recommended that units be in accessible locations not more than 10 seconds away from the hazard, on the same level as the hazard, and free from obstructions that may inhibit its immediate use.

What is included with the AXION eyePOD?

The AXION eyePOD comes with four common faucet adapters to allow the unit to mount onto almost any faucet. It is pre-assembled and has a .5 GPM (1.89 LPM) multi-stream faucet flow and an optional 1 GPM (3.78 LPM) single stream laminar faucet flow. Lastly, the unit comes with the ANSI Z358.1 Standard required signage and easy-to-understand installation, usage and maintenance instructions.

How do I install it?

Included with the eyePOD are a variety of industry standard adapters that allows it to be mounted onto most standard faucets. Unscrew the existing aerator from the bottom of your faucet and replace it with the eyePOD. Installation videos are available at www.axioneyepod.com

What certifications does the AXION eyePOD have?

The AXION eyePOD is certified by CSA to meet ASME A112.18.1/CSA B125.1 and ANSI Z358.1 Standards for Emergency Eyewash and Shower Equipment. Product is compliant to NSF 61, California Health and Safety Code 116875 (AB 1953) and NSF/ANSI 372, along with all current Federal Regulations for the disabled including those in the Americans with Disabilities Act when properly installed on an ADA compliant faucet/sink with knee clearance installation.

How often do I need to test the unit?

As per the ANSI Z358.1 Standard, the unit should be activated weekly to ensure proper performance. The unit can be easily tested witusing our ANSI Z358.1 checklist (available on www.hawsco.com).

Is there a risk of having the water too hot?

Is there a risk of having the water too hot?

No. The eyePOD features a built-in thermostatic safety valve that will automatically shut off eyewash flows at 100°F (37°C), diverting all water out through the aerator faucet at the bottom of the unit. This protects users from accidentally irrigating their eyes with water that is too hot. When water temperatures fall to an acceptable degree (below 100°F), eyewash flows are automatically restored. You do not need to replace the thermostatic safety valve if activated.

How do I clean and care for the unit?

We recommend using a mild soap and water combination when outside cleaning of the unit is required. The AXION eyePOD is self-draining when placed in the downward faucet mode and should always be returned to this mode after eyewash use to allow for drainage.

Why does this unit look so different from others on the market?

It is the only unit to contain a built-in thermostatic safety valve and to feature AXION MSR technology providing an inverted water flow pattern consistent with first aid protocols. This directional flow mitigates the risk of inhalation or ingestion of hazardous contaminants via the tear ducts during eye cleansing. Traditional eyewashes irrigate eyes in the opposite manner, potentially further injuring the victim’s eyes and nasal cavity. The eyePOD is the only faucet-mounted eyewash that duplicates healthcare professional methodology by flushing from the inside-out.

To order your own eyePOD, visit the product page>>

To download this FAQ Document, click here>>

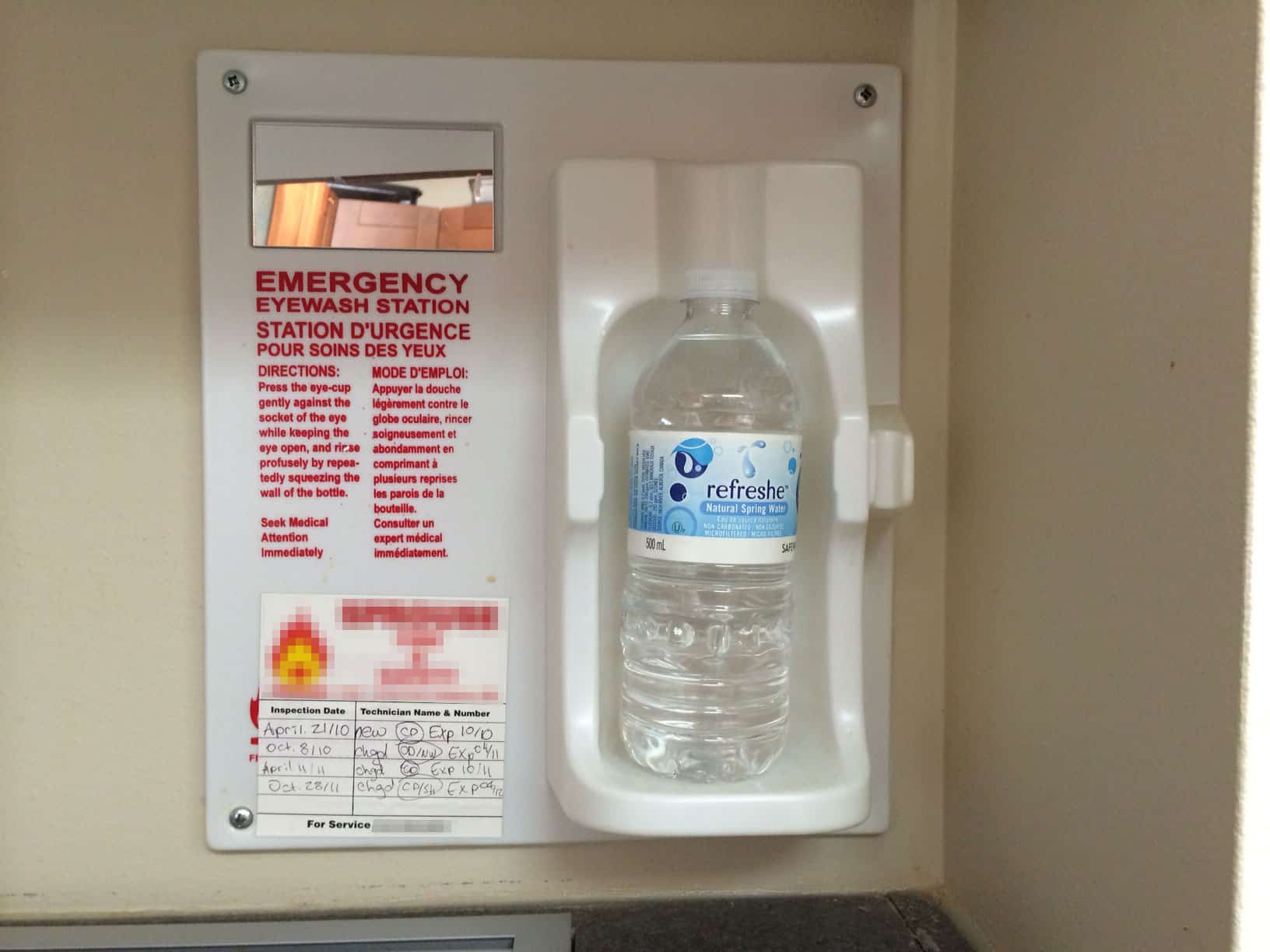

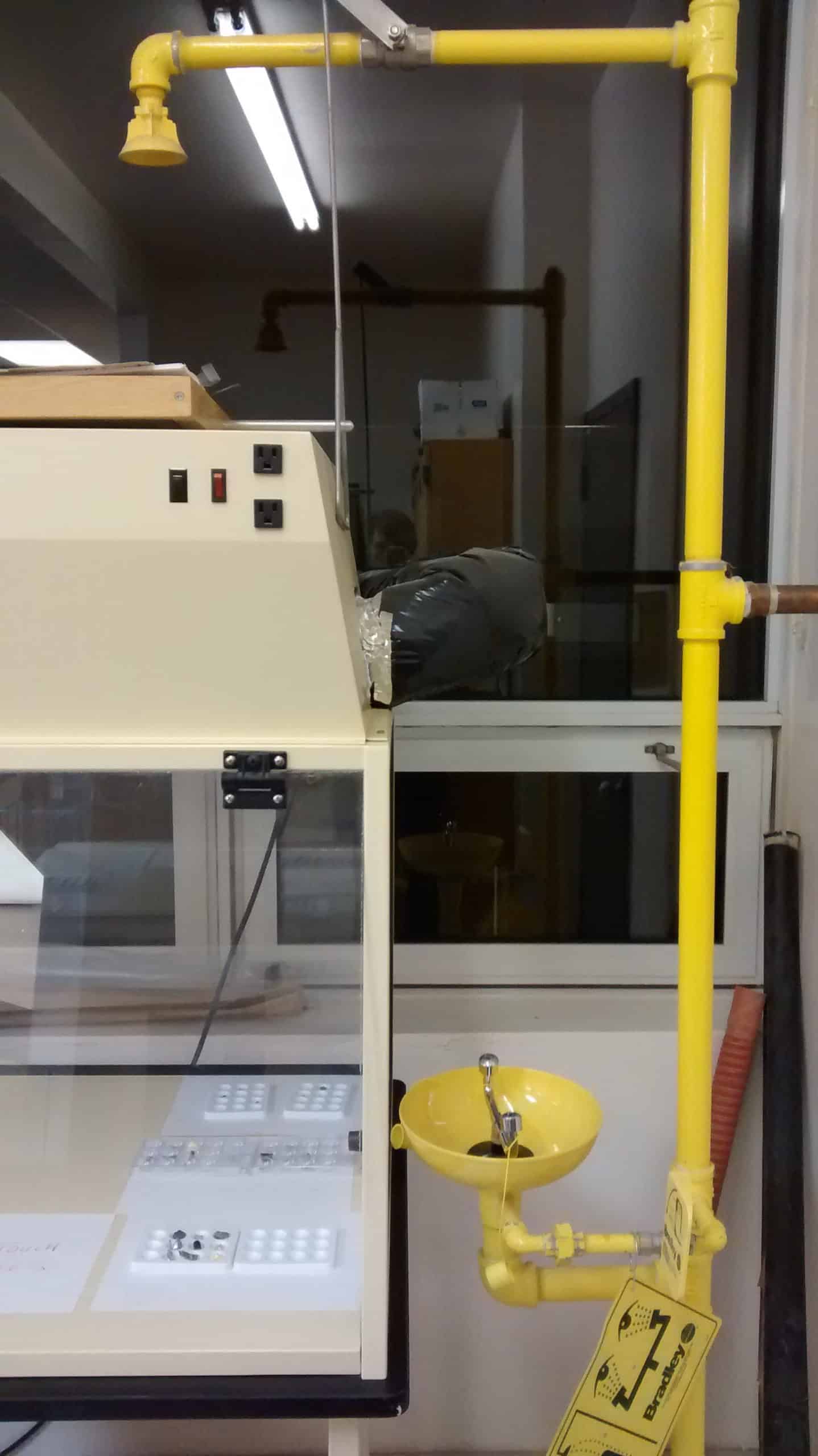

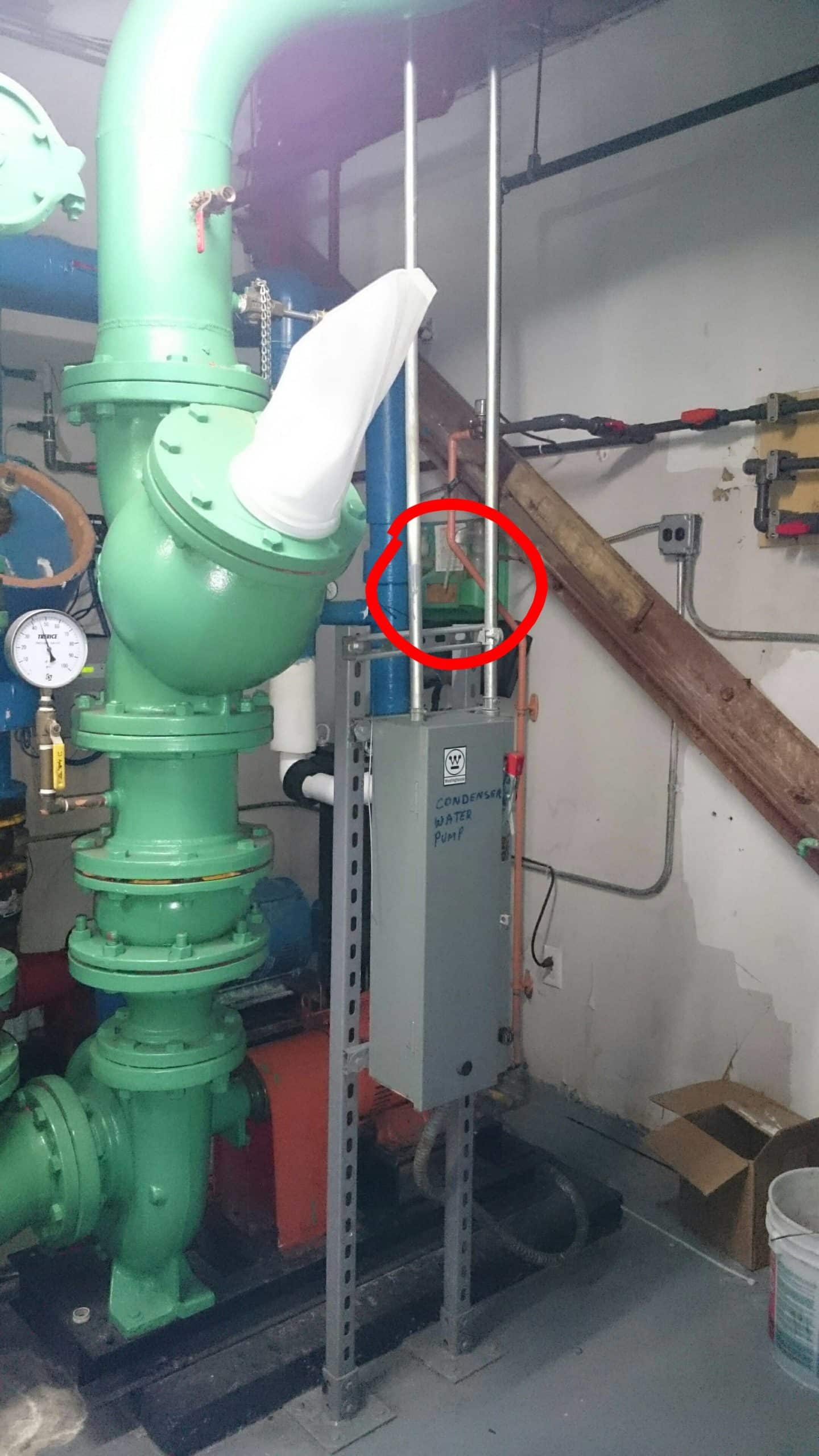

Monday Tip: Emergency Eyewash “No-No’s”It is interesting to see what some facilities consider to be sufficient in regards to providing proper emergency shower and eyewash equipment. Below are just a few of these not-so-compliant “solutions”.

Not only does this risk potential fines from OSHA for not complying with the ANSI Z358.1 Standard, but it also put workers, students, etc. at risk of not having proper functioning equipment to use in the event of an emergency.

Ummm… not quite an equivalent.

I wonder where the user is supposed to stand?

Ever seen a dual-functioning water cooler and eyewash station? Yeah, neither have we.

Can you spot the eyewash station?

Our tip: When installing an eyewash or shower unit, test out an emergency scenario to make sure you are giving a victim the required distance and access. Choose the path of least resistance to guarantee a victim the best treatment possible and to reduce potential injury damage.

For more information on ANSI installation requirements, visit www.hawsco.com/ANSI .

Have You Seen a Haws?Have you seen a Haws product installed out in the field? If so, hashtag #Haws for a chance to win a $25 Starbucks card!

AXION® eyePOD® from a Toronto based dental practice. @targetcontracting

Antique Haws drinking fountain in Arizona. @iamkalin

Brita® Hydration Station® installation on UNLV campus. @ttbtatunlv

Haws bubbler head. @rusticranger

Haws eyewash poster. @moxymoth

Your Guide to 2014 ANSI Z358.1 Revisions & Best Practices by Casey Hayes

Haws Integrated Director Casey Hayes, is featured in Industrial Safety & Hygiene News (ISHN) April issue with an article titled “Emergency Showers and Eyewash Stations: Your Guide to 2014 ANSI Z358.1 Revisions & Best Practices”. In the article, Hayes provides helpful insights on how to properly use emergency showers and eyewash stations, for maximum victim comfort and ANSI compliance.

Haws Integrated Director Casey Hayes, is featured in Industrial Safety & Hygiene News (ISHN) April issue with an article titled “Emergency Showers and Eyewash Stations: Your Guide to 2014 ANSI Z358.1 Revisions & Best Practices”. In the article, Hayes provides helpful insights on how to properly use emergency showers and eyewash stations, for maximum victim comfort and ANSI compliance.

In an effort to establish minimum performance and use requirements for emergency eyewash and shower equipment, the American National Standards Institute (ANSI) created industry standard ANSI Z358.1 in 1981.”

To view the complete article click here!

Upcoming ASSE Safety Expo in DallasAre you attending the upcoming ASSE Safety 2015 Expo in Dallas, Texas? If so, come say hi to us! You can find Haws Corporation® at booth number 540, and grab a free reusable Nalgene® bottle while you’re at it!

Come learn more about our various product offerings including our emergency shower and eyewash retrofit kits. The AXION Advantage® upgrade systems offer a medically superior response for upgrading existing competitive emergency eyewash and shower equipment while exceeding ANSI compliance. You’ll also want to check out our AXION® eyePOD® faucet-mounted eyewash that will be a working display at the show.

We look forward to seeing you!

AXION’S ground-breaking technology continues to change the emergency response landscape by offering the only eye/face wash duplicating the methodology recommended and used by medical professionals.

Listen to the Introduction to AXION MSR Technology by watching this video.

For more information on the AXION Technology and Haws products that have this technology, click here.

The Beginner’s Guide to Eyewash Testing Gauges

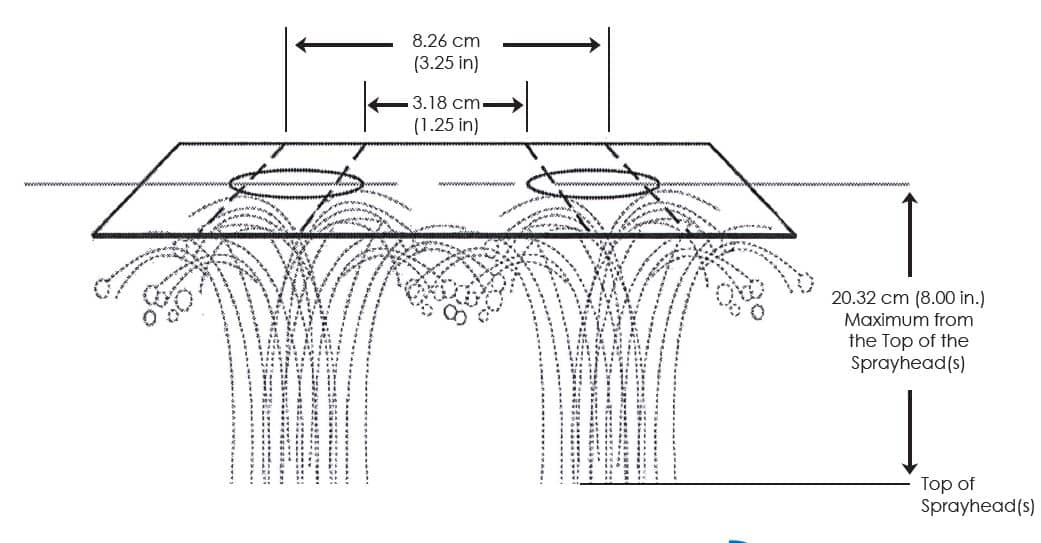

The ANSI Z358.1 Standard states that to determine a suitable eyewash pattern, the eyewash testing gauge should be a minimum of 4 inches in length with two sets of parallel lines equidistant from the center. The interior of the lines should be 3.25 inches apart. (Section 5.1.8)

1. Activate the eye/face wash. Note: If the eye/face wash is a part of a combination unit, ensure all other outlets are activated to confirm proper flow and simultaneous use. (Section 7.1)

2. Place the testing gauge in the streams of the eyewash. (Section 5.1.8)

3. The flushing fluid should cover the areas between the interior and exterior lines of the gauge at some point less than 8 inches above the eyewash nozzle. (Section 5.1.8)

OSHA Fine For Lack of Proper Eyewash EquipmentFebruary 8, 2014

A mining company was fined by OSHA totaling $5,776. In their inspection, they found that employees were exposed to fire hazards and risk of eye injuries.

“The second violation designated as serious states that employees were at risk of eye injuries while handling corrosive chemicals, such as hydrated lime, copper sulfate and sodium hydroxide, without access to a suitable eyewash facility in the immediate area.

This violation brought with it a fine of $1,951.”

To read the full article on Star Mine Operations OSHA citations, click here.

Case Study: Aquatics Center for the City of St. AlbertEye safety can be overlooked in environments that do not often deal with hazardous materials. In the circumstance of an aquatics club, some employees are exposed to pool cleaning chemicals that are dangerous to the eyes if exposed. Looking to transition away from personal eyewash bottles, the Aquatics Department for the City of St. Albert in Alberta, Canada led their eyewash needs to the AXION® eyePOD®.

The design of the AXION eyePOD blends gracefully with the design of the first aid center of the Aquatics Center. The staff are thrilled that the AXION eyePOD is easy to use and has an internal temperature gauge that will shut off the water once it reaches 100° F. In addition, the staff no longer fears being exposed to calcium hypochlorite or sodium hypochlorite. The AXION eyePOD proved to be the perfect first aid solution.

Read more about the The Aquatics Department for the City of St. Albert in Alberta, Canada’s eyePOD.

To learn more visit AXION eyePOD.