Do you know the protocol to flushing hazardous chemicals off of your body in an emergency? It’s always a good rule of thumb to be knowledgeable on how to properly execute safety shower and eyewash performance in an emergency situation. Take the time to get to know the mechanics of the emergency equipment in your facility before an accident takes place. Casey Hayes, director of Haws Integrated™, recommends the following:

- Get a proper training session on emergency equipment. Be aware of the location of the unit and how long it takes to arrive at the unit from your work space.

- Confirm that it should not take more than 10 seconds to arrive to the emergency equipment.

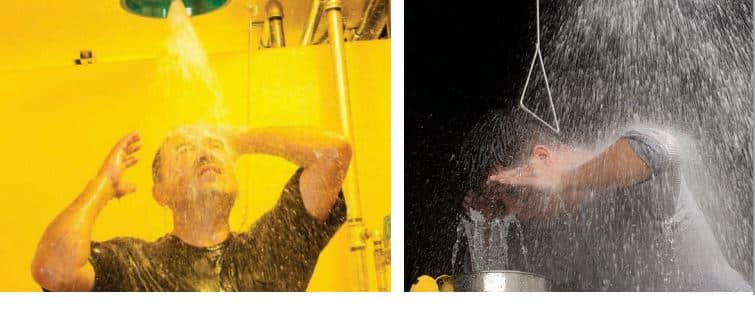

- Upon arrival to the shower, pull lever and remain in shower for a full 15 minutes. This is to ensure the prevention of chemical absorption while it also helps to cool burns and prevent hypothermia.

- When using an eyewash or eye/face wash, hold eyes open during the entire 15 minute flushing period.

- In some cases, it may be appropriate to have a partner with you during the state of emergency. If you work alone, you may not have the opportunity to have someone assist you. We recommend that if you are in a state of shock, have a co-worker assist you to the emergency shower and or eyewash station. If you are saturated in chemicals, it is best not to expose anyone else and to proceed to the emergency station alone.

- Always go to the emergency room following the use of the emergency shower and/or eyewash.

Furthermore, it’s essential to have functional emergency showers and eyewashes throughout your facility. Refer to our previous blog post ANSI Z358.1 FAQ: What is the Weekly vs. Annual Test for a break down on when it is appropriate to perform each test. We also offer a free webinar on the requirements for emergency eyewashes and showers. Click here to watch.

Antsy about ANSI? 5 Common FAQ’s

Questions answered by ANSI subject matter expert and Director of Haws Integrated Operations, Casey Hayes.

Is testing of the safety showers and eyewashes actually required in the standard and not just the appendix?

Yes, it is part of the standard. It is not in the appendix. We talk about the weekly flush and the requirements to get the debris out and to ensure that water is available. And, we also discuss in the standard the requirements for the full ANSI annual test. The annual test ensures things like making sure we have 20 gallons per minute to the showerhead and that the spray pattern of the shower meets the requirements. Same for the eyewash. It is also when you will test to make sure it is 10 seconds from the hazard and nothing is obstructing the pathway of victim reaching the unit.

2. Does the accessible 10 second rule apply to a fast pace walk or run?

In previous revisions, there was a distance in the requirement. At one point, we had 10 seconds and 100 feet. At another point, we had 10 seconds and 55 feet. We have taken out the distance requirement so that we don’t have to determine whether it is a walk or a run. We are putting that back onto the installation aspect for you to determine what 10 seconds looks like. In the appendix, it does talk about 55 feet which is probably the right distance, but the standard does not get into the details.

3. Does EPA prohibit floor drains in college chemistry labs?

I have never been asked about this as far as EPA. I do know that the ANSI Z358.1 standard is strictly a performance standard and does not talk about floor drains because they are concerned about the performance of the shower. So, floor drains have nothing to do with that. If you look at plumbing codes, it specifically says that floor drains are not required. We believe that is due to the fact that they don’t want water that has chemicals in it to go to the sewer drain. I have never seen anything related to EPA.

4. Can you please reference the OSHA standard that requires testing once a week?

CAL OSHA says they only enforce once per month. OSHA specifically does not talk about anything in regards to the performance of the safety shower. It specifically says it must supply a suitable facility. It does not get into specifics as to what a suitable facility is. OSHA is starting to reference the ANSI standard as a guideline as to what a suitable facility is but nowhere in OSHA do they talk about the testing of the equipment. If you are building to the plumbing code, specifically references that the shower must meet ANSI and therefore the requirement for weekly/annual testing comes into play.

5. Are written records of testing required on-site?

This is outside the ANSI standard. This is what I would call a best practice. We are seeing that the testing validation is not on the tag on the shower but not being placed with the health and safety time. Testing has been enhanced so people are collecting and filing it away.

Learn more about ANSI by registering for our upcoming live web seminar on ANSI Z358.1-2014 Compliance.

Web Seminar Invitation: ANSI Z358.1 Compliance GuideWeb Seminar Invitation:

ANSI Z358.1 Compliance Guide

PRESENTER: Casey Hayes, Director of Haws Integrated™ Operations

DATE: Thursday, February 18th

TIME: 10am-11am PT/1pm-2pm ET

Take advantage now by registering.

In November 2015, it was signed into law that OSHA fines are increasing by 80% for the first time since 1990. Ensure you are complaint with the updated ANSI Z358.1 Standard to avoid fines and guarantee you are providing properly functioning emergency equipment.

Hosted by leading ANSI compliance field expert Casey Hayes, this FREE web seminar will cover:

• ANSI Z358.1-2014 revisions and significant requirements

• Compliance best practices

• Live Q and A

Attendees will receive:

• Complimentary OSHA white paper

• ANSI checklist

• Access to on-demand webinar

About Haws IntegratedTM

Haws IntegratedTM designs, builds, and manages custom-engineered industrial safety systems that provide tempered water when and where it is needed.

Featured Editorial: Top considerations for emergency equipment specification, installation Business and Industry Connection’s (BIC) August issue features an editorial by Casey Hayes, Director of Sales and Operations for Haws Integrated™, where he discusses the five factors to consider for emergency specification, installation.

Business and Industry Connection’s (BIC) August issue features an editorial by Casey Hayes, Director of Sales and Operations for Haws Integrated™, where he discusses the five factors to consider for emergency specification, installation.

Recommendations include details on:

- Equipment location

- Assuring visibility

- Product suitability

- Tempered water requirement

- Assuring proper maintenance

To read more from the Haws Integrated™ White Paper feature, you can visit BIC Magazine (page 73). Also, visit Haws Integrated™ for a full range of ANSI-compliant solutions!

And if you’re attending the National VPPPA Conference, come visit us at booth number 1010!

Trends in Emergency Eyewashes and ShowersQuick access to an emergency eyewash/shower station is vital in the event of an incident. “The first 10 to 15 seconds after exposure to a hazardous substance, especially a corrosive substance, are critical,” the Canadian Center for Occupational Health and Safety states. CCOHS goes on to note that delaying treatment, even for just a few seconds, may result in serious injury to a worker. Below, industry insiders discuss common mistakes regarding emergency eyewashes/showers, and what’s new in the field.

How mistakes happen

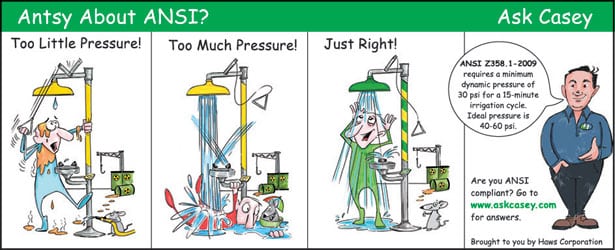

Water temperature issues and lack of testing are common mistakes that occur with emergency eyewashes/showers. If the water is too cold – or too hot – the user is much less likely to withstand the full 15-minute flush.

Casey Hayes, director of integrated sales and operations for Sparks, NV-based Haws Corp., also spoke of issues with not flushing for the full 15-minute period. “This is attributed to either product deficiency or improper training,” Hayes said. “Weekly and yearly testing will mitigate against product issues, but it’s important to frequently train and re-train team members.”

Advancements

Comfort is, not surprisingly, a driving force when it comes to product advancements. “Eyewash and safety showers are transitioning to focus on victim comfort and ease of use as the primary features,” Hayes said. “This includes smooth water flows for comfortable water pressure, internal flow control to match ANSI Z358.1 flow and velocity requirements, and a reasonable water temperature to encourage a full 15-minute flush.”

So what’s the most important thing workers should know concerning emergency eyewashes and showers? According to Hayes, it’s the ability for workers to know how to operate emergency equipment. “If a victim cannot properly use the equipment for the required time there is a potential for increase of injury and associated liabilities,” he said.

ANSI Z358.1 Compliance presentation by Haws® at the Upcoming ASSE Safety ExpoIf you are attending the upcoming ASSE Safety 2015 Expo in Dallas, plan to attend Haws‘ presentation on the ANSI Z358.1 Standard. Our very own Casey Hayes, Director of Haws Integrated™ Sales and Operations, will be the speaker at the show on June 8th from 10:20 am – 11:45 am. The topic of his presentation is “Meeting and Exceeding the ANSI Z358.1 Standard for Emergency Equipment.” This is session 527.

While you’re at it, stop by our Booth #540 and grab a free, reusable Nalgene® bottle! Come learn more about our various product offerings including our emergency eyewash and shower retrofit kits. The AXION Advantage® upgrade systems offer a medically superior response for upgrading existing competitive emergency eyewash and shower equipment while exceeding ANSI compliance.

We look forward to seeing you!

Repost: 2014 Emergency Eyewash, Shower Standard Revision RecapBy Roy Maurer, online editor/manager for Society for Human Resource Management

The national consensus standard for the selection, installation and maintenance of emergency eye, face and shower equipment was recently updated.

The International Safety Equipment Association (ISEA) received American National Standards Institute (ANSI) approval for ANSI/ISEA Z358.1-2014, American National Standard for Emergency Eyewash and Shower Equipment, and the update went into effect January 2015.

There is no grandfather clause, and existing equipment must be compliant with the revised standard.

“This globally accepted standard continues to be the authoritative document that specifies minimum performance criteria for flow rates, temperature and drenching patterns,” said Imants Stiebris, chairman of the ISEA Emergency Eyewash and Shower Group and safety products business leader at Speakman Co.

The Occupational Safety and Health Administration (OSHA) has a general requirement specifying where and when emergency eyewash and shower equipment must be available, but it does not specify operating or installation requirements.

That’s where the ANSI/ISEA standard comes in. While it doesn’t have the full force of an OSHA regulation, the standard helps employers meet OSHA requirements.

“Safety showers and eyewashes are your first line of defense should there be an accident,” said Casey Hayes, director of operations for Haws Integrated, a firm that designs, builds and manages custom-engineered industrial water safety systems. “We’ve seen OSHA stepping up enforcement of the standard in the last couple of years and issuing more citations,” he said.

What Is ANSI/ISEA Z358.1-2014?

The standard covers plumbed and self-contained emergency showers and emergency eyewash equipment, eye/face wash equipment, combination units, personal wash units and hand-held drench hoses. These systems are typically found in manufacturing facilities, construction sites, laboratories, medical offices and other workplaces.

The standard specifies minimum performance criteria for flow rates, temperature and drenching patterns for a user to adequately rinse off a contaminant in an emergency situation. It also provides maintenance directives to ensure that the equipment is in proper working condition.

One of the most significant requirements of the standard deals with the location of the equipment, Hayes said, and “It’s probably the most difficult part for employers to comply with.” The equipment must be accessible to workers within 10 seconds—a vague requirement, according to Hayes—but the standard’s appendix references 55 feet, he pointed out.

The wash or shower must be located on the same level as the hazard. “You can’t have somebody working on a stairwell and have to go up or down a flight to get to the shower. The equipment needs to be installed on the same level where the accident could happen,” he said.

The wash station must also be free of obstructions. “Someone needing to get to the shower or eyewash could be in a panic—their eyes could be blinded by chemicals—so employers must ensure that the shower is accessible and free of obstructions,” he said.

All equipment must be identified with highly visible signage, must be well-lit, and needs to be able to go from “off” to “on” in one second or less.

“The volume of water that is required for a 15-minute flow is not always considered,” Hayes said. The standard requires the victim to endure a flushing flow for a minimum of 15 minutes. With water pressure from the drench shower 10 times the amount of a typical residential shower, “that is a significant amount of water, and you need to deal with it on the floor and from a capacity standpoint,” he said.

The comfort of the person using the wash also needs to be considered. “It is not a pleasant experience to put your eyes in the path of water. The controlled flow of flushing fluid must be at a velocity low enough to be noninjurious to the user,” Hayes said.

The standard stipulates minimum flow rates of:

- 0.4 gallons per minute for eyewashes.

- 3 gallons per minute for eye/face washes. A good eye/face wash will have separate dedicated flows of water for your eyes and face, Hayes said.

- 20 gallons per minute for showers. That’s 300 gallons of water required for the 15-minute wash.

Washes must deliver tepid water defined as between 60 degrees and 100 degrees Fahrenheit.

Studies have shown that tepid water increases the chances that a victim can tolerate the required 15-minute wash. Tepid water also encourages the removal of contaminated clothing, which acts as a barrier to the flushing fluid.

“We’re also seeing employers putting showers in enclosed areas or in curtained areas, to promote the removal of clothing and alleviate workers’ privacy concerns,” Hayes said.

2014 Revisions to the Standard

There weren’t that many changes to the 2009 standard, but a few highlights include the following:

- A requirement was included that emergency showers be designed, manufactured and installed in such a way that, once activated, they can be operated without the use of hands.

- The way the height of eyewashes and eye/face washes are measured changed from the floor to the wash basin to from the floor to the water flow. The height should still be between 33 inches and 53 inches. “Something to consider when inspecting washes is to ensure that, even though your wash fits within these limits, it’s still realistically usable,” Hayes said.

- A single step up into an enclosure where the wash is accessed is not considered an obstruction. This had not been addressed previously.

The 2014 version further clarifies that fluid flow location and pattern delivery for emergency eyewashes and eye/face washes is the critical aspect in designing and installing these devices, rather than the positioning of nozzles. Additionally, illustrations have been updated to reflect contemporary design configurations.

Best Practices

Hayes recommended a few best practices that go above and beyond the standard and that he has seen used at companies with strong safety cultures:

- Locate washes and showers in areas with adequate space for emergency responders to fulfill their duties. “If the equipment is in a tight space, you’re preventing responders from helping victims,” he said. Enclosures can be built to allow multiple people to be inside.

- Monitor and evaluate all accessible components of washes and showers on a frequent and routine basis to manage potential problems.

- Use eye/face washes in lieu of simply eyewashes. “It’s highly unlikely that a chemical splash will only land on your eye surface. This is common sense, so put in the right equipment,” he said.

- Check that the washes meet the proper gauge height. The standard’s weekly activation requirement is mainly to ensure that water is available and to clear sediment buildup. “While a quick activation might seem sufficient, it’s not an accurate representation of functionality for the required 15-minute flush,” Hayes said. “If water is there but doesn’t rise up to the proper gauge height, you are compliant, but that equipment may fail you in the event that it’s needed.”

The ISEA’s new Emergency Eyewash and Shower Equipment Selection, Installation and Use Guide is a document that provides assistance on the proper selection, use and maintenance of equipment. The 22-page guide includes a frequently asked questions section and an annual inspection checklist.

The guide is available for download in PDF format.

[via SHRM]

ASK CASEY: What’s the Proper Pressure For a Safety Shower?